- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

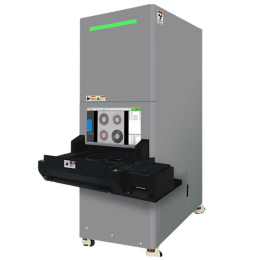

Offline Automated Inspection System A-400

A-400 is an offline AOI equipment for SMD component & THT component sodering joint inspection. it's equipped with HD digital camera and advanced algorithm, which can precisely and quickly detect SMD components and soldering joint, reduce the misjudgement rate. At the same time, the machine uses intelligent color algorithms to assist the operator in debugging the program, making programming easier.

Available Options

Offline Automated Inspection System A-400

×|

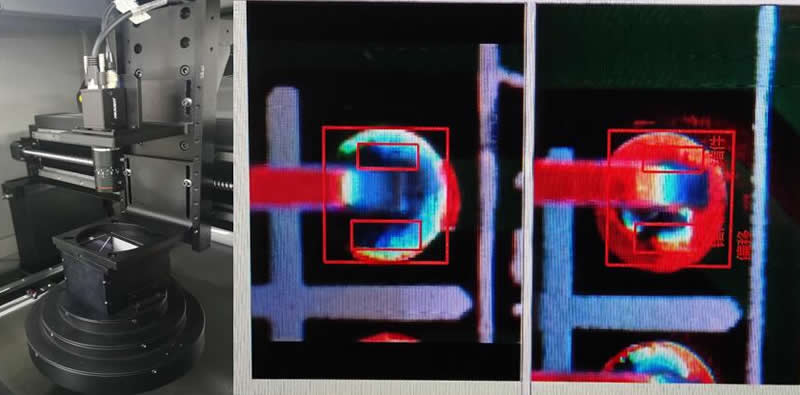

4-channel lighting source system ● 4-channel light source system is specially designed for PCBA inspection. RGB multi-angle ring light can reflect the 2D information of solder joint. Professional optic architecture design ensures the evenness of light distribution within each FOV, which reduces the false call rate significantly while ensure to catch the defects.

|

|

|

|

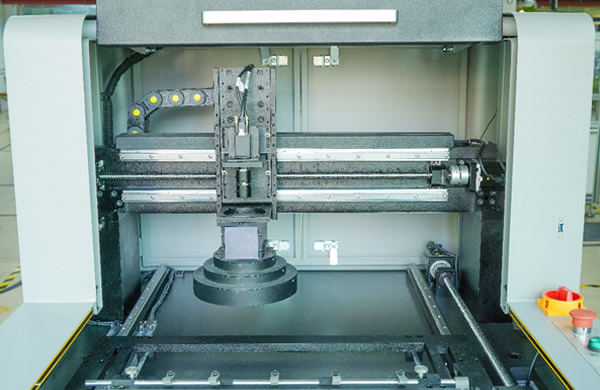

● The X/Y axis of the machine is controlled by servo and grinding screw, and the positioning accuracy of the machine is high. |

|

|

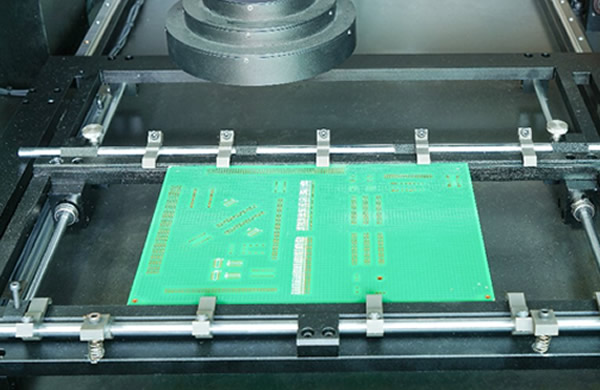

● A fully automatic device for clamping PCB boards, it is very convenient to install and pick up PCB boards |

|

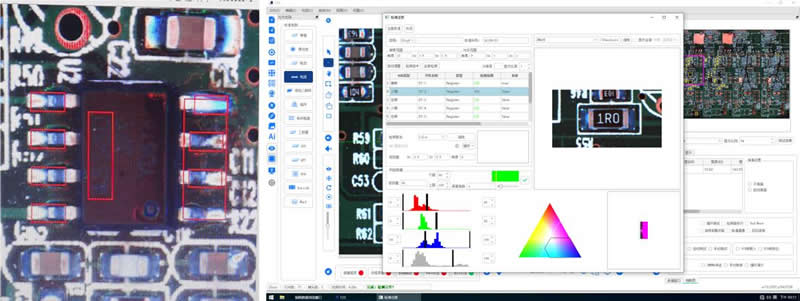

The software adopts the color algorithm, the software can automatically adjust the range of detection acquaintance according to the color of the solder joints, and the programming is simple.In the software, each detection position can be edited separately, and different upper and lower limit detection acquaintance values can be set to ensure the accuracy of detection.

|

|

|

SMD Component Detection item: Missing, Reversed, Shift, Damaged, Skew, Redundant, Foreign material.

|

|

|

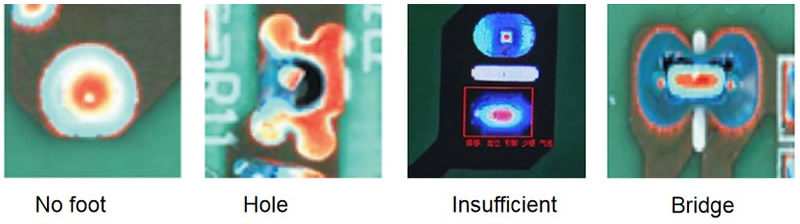

THT Solder Joint Detection item: excess, insufficient, no foot, bridge, hole etc.

|

|

|

Offline Automated Inspection System A-400 Features |

|

● High stability platform ensure machine running fast and stably. |

|

● X/Y servo motor with high precision ball screw driving system ensures running accuracy. |

|

● Equipped with 5M pixels CCD with RRGB 3 color light source to ensure inspection accuracy. |

|

● Detection SMT items: Wrong,Miss, Reversed, Skew, Redundant, shift, foreign matter. Solder detect: excess, insufficient, no foot, bridge. |

|

● THT solder joint detection:excess , insufficient , no foot , bridge ,hole etc. |

|

● Easy programming: Automatically load CAD data to position component ,and search component library. |

|

● Equipped with Data statistics software, easy to search and export detailed statistical data. |

|

● Equipped with barcode reading system. |

|

Offline Automated Inspection System A-400 Specification: |

||

|

Model |

A-400 |

|

|

Image System |

Camera | Top 5M pixels Camera |

| Resolution | Standard :15um | |

| Lighting | 3 color ring shape LED(RGB) | |

|

Motion System |

X/Y Movement | AC Servo motor ball screw and linear rail. |

|

Hardware |

PC configuration | I5, 4 core, 8G RAM, hard disk: 500G ROM |

| Power Supply | 1P, 220V,50/60Hz , 1KW | |

| Machine Size | W953*D1160*H1533mm | |

| Weight | 486kg | |

|

Software |

Operation System | Windows 10 |

| Programming | CAD file loading, manual teaching. | |

|

PCB Size |

Size | 50*50-450*360mm |

| Thickness | ≤6.0mm | |

| Clearance | Top/Bottom:40/60mm | |

| Clamping Edge | >3.0mm | |

|

Inspection Catagories |

SMT Component | Wrong, Miss, Reversed, Skew, Redundant, shift, foreign matter. Solder detect: excess, insufficient, no foot, bridge |

| THT solder joint | excess, insufficient, no foot, bridge,hole etc. | |

| Inspection Component | Chip:0201 ( 15um lens). | |

|

Offline Automated Inspection System A-400 Includes: |

|

Standard configuration: |

|

1.A-400 Automated Optics Inspection Machine |

|

|

|

Optional: |

|

1. Offline programming software |

0 review for Donec eu furniture

Related Products

X-Ray Counter SoYi-C2

- Model: SoYi-C2

SMT Component Automated Inspection System SA-500

- Model: SA-500

S-350/S-600 Series Desktop SPI Machine

- Model: S-350/600

S-460i/600i Inline SPI Machine

- Model: S-460i/600i

Add a review

Your email address will not be published. Required fields are marked