- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

Intelligent Component Insertion System AI-400

AI-400 Standard Insertion platform with various component feeder which can easily help you realize insertion automation especially for combined standard and odd shape components.

Available Options

Intelligent Component Insertion System AI-400

×Intelligent Component Insertion System AI-400 Features: |

| ● Compact machine size, can be easliy intergrated into production line help you realize insertion automation especially for combined standard and odd shape components. |

● High rigidity beam structure design, X/Y/Z axis driven by servo motor, equipped with 6 heads, advanced motion control algorithm and visual algorithm to achieve high speed, high quality insertion. |

● Modular design, according to different feeding methods to provide virious feeding solutions. according to production requirements to provide flexible configuration, to meet pin components, irregular components of continuous feeding. |

● Cutomized clamping head can install maximum 6 clamping jaws satisfy multiple odd shape components insertion requirement. |

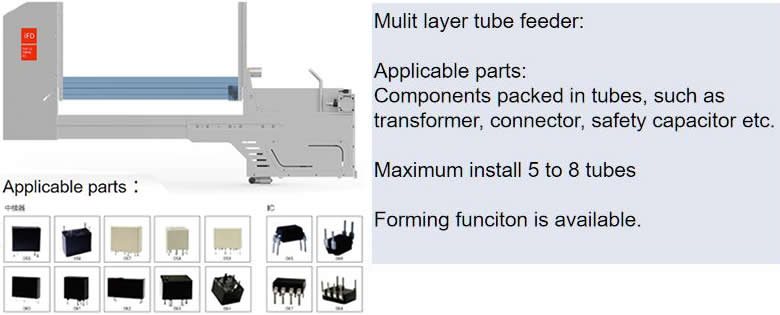

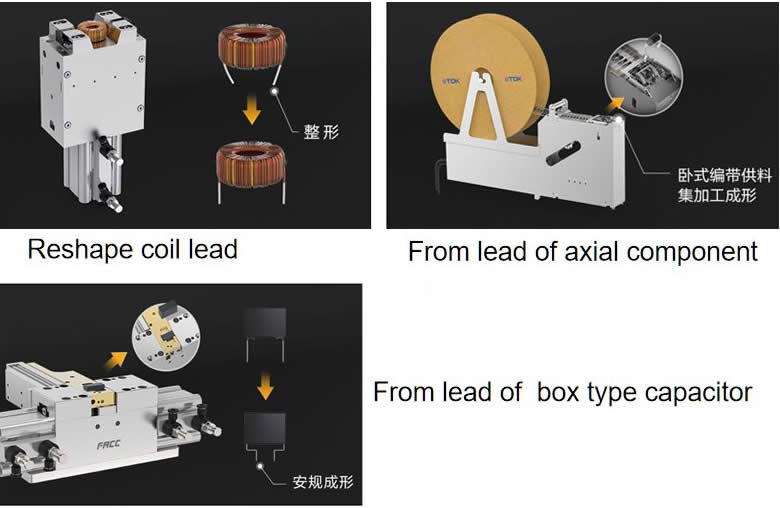

● Various feeder type even with forming funciton can meet mutiple component feeding and forming requirement. |

● 3 section conveying system with motorized width adjustment and clamping mechanism is applicable for max L400*W400mm PCB. |

● Insertion abnoramal detect function can realize machine alarm, by pass and immediate re-insertion function. |

● Extraordinary vision system, pin quality, appearance contour and coordinate position of components can be accurately detected and positioned. realize ±0.05mm insertion accuracy. |

● Windows based software, full English interface, easy to operate. |

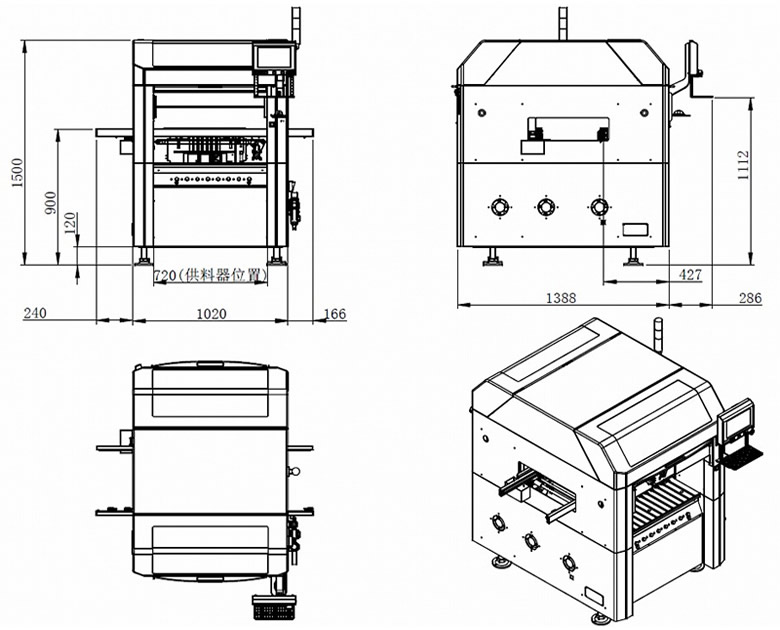

| Intelligent Component Insertion System AI-400 Dimension |

|

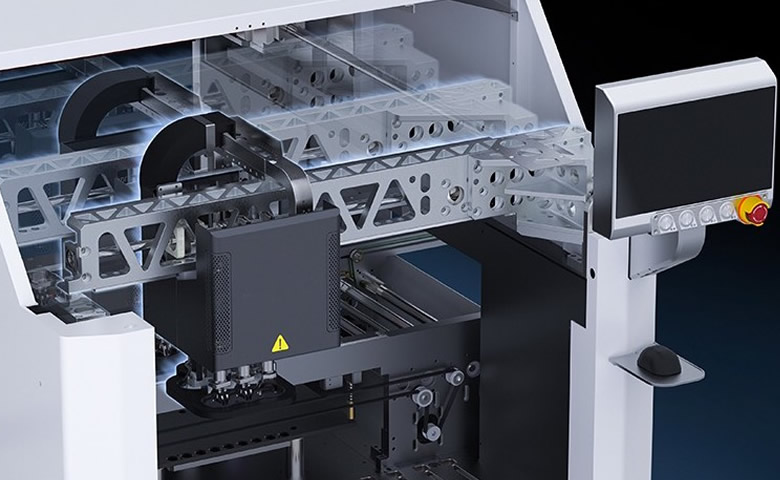

| Intelligent Component Insertion System AI-400 Robot |

| High rigidity beam structure design, X/Y/Z axis driven by servo motor, equipped with 6 heads, advanced motion control algorithm and visual algorithm to achieve high speed, high quality insertion. |

|

| Intelligent Component Insertion System AI-400 Clamping head: |

Multi functional clamping Heads with optional automatic changing function: |

----Leading performance, an abundant choices of clamping jaws and suction cups to offer protection for complicated insertion work. |

|

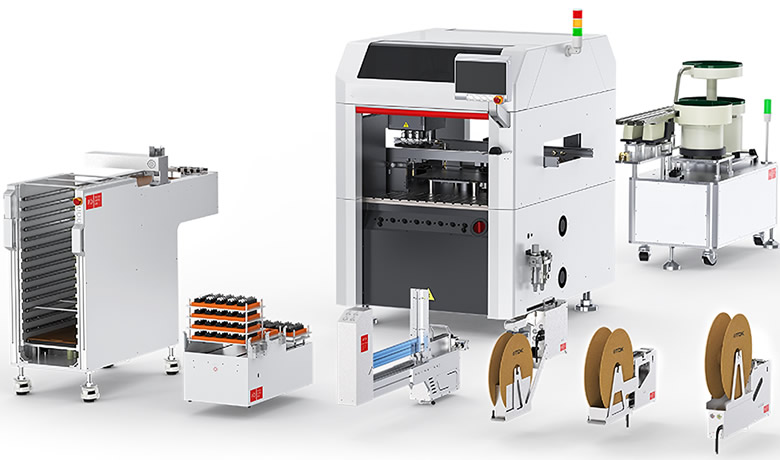

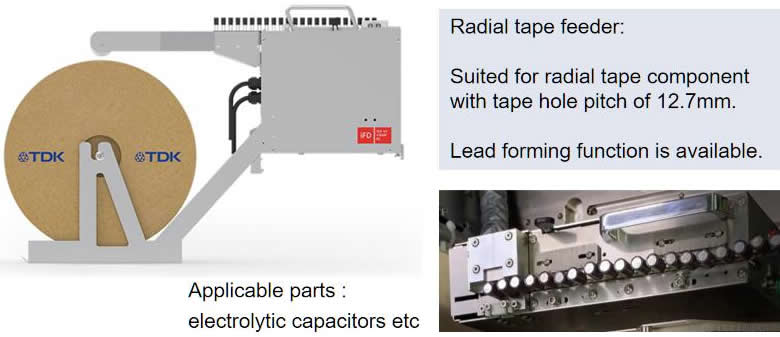

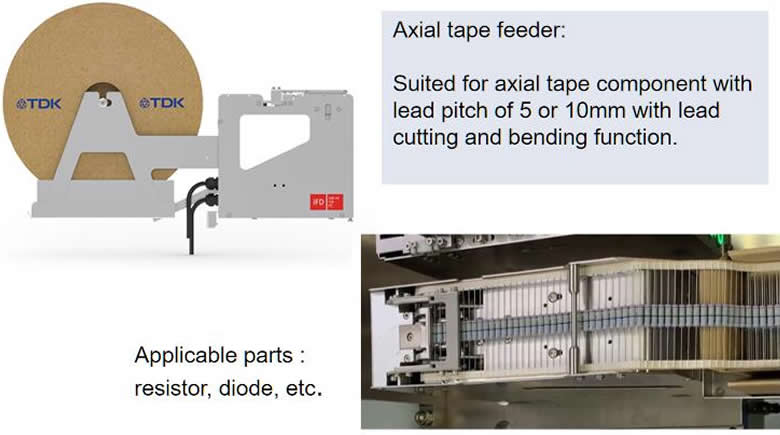

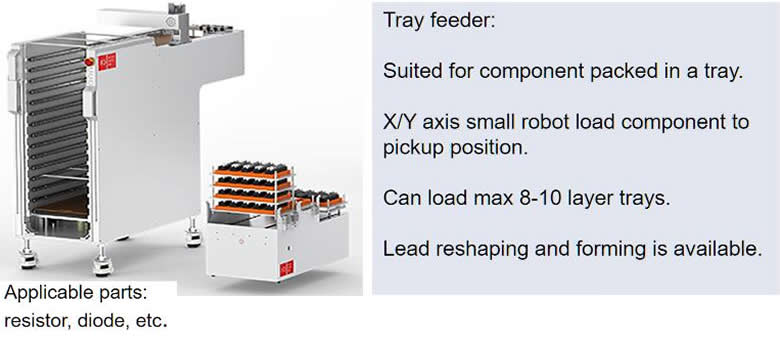

| Intelligent Component Insertion System AI-400 Feeders |

| Various feeder type even with forming funciton can meet mutiple component feeding requirement and easily help you realize high insertion automation . |

|

|

|

|

|

|

|

| Intelligent Component Insertion System AI-400 Software |

Easy to Program and Operate |

● Graphical User Interface ● CAD and CSV Import fucntion ● English interface available |

|

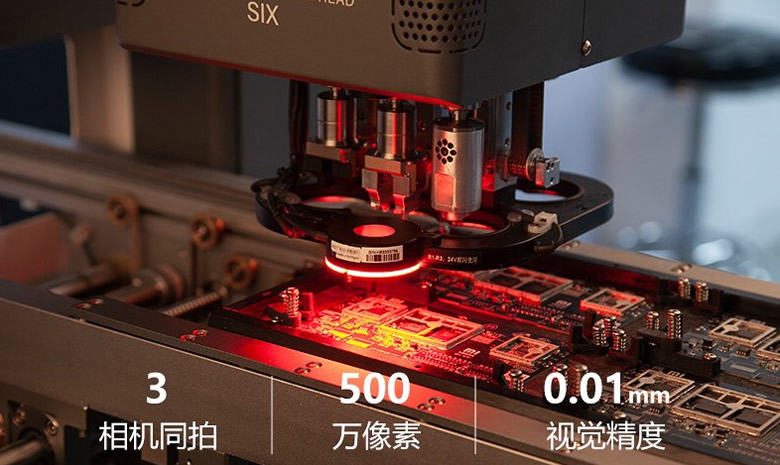

| Intelligent Component Insertion System AI-400 Vision System: |

| Extraordinary vision system, pin quality, appearance contour and coordinate position of components can be accurately detected and positioned. realize ±0.05mm insertion accuracy . |

|

● 3 camera photograph simultaneoously ● 5 million pixel ● 0.01mm vision accuracy |

Intelligent Component Insertion System AI-400 Specification | ||||

MACHINE Model | AI-400 | |||

PCB dimension | PCB size | maximum size | standard (W)400 x (D)400mm | |

| minimum size | W50*D70mm | |||

PCB transport direction | Left to right, 3 section conveyor | |||

Driving method | X/Y/Z/R | Driven by servo motor | ||

Insertion parameter | Insertion speed | theoretical speed | 6000 CPH | |

| actual speed | 0.8 s/pc to 1.2 s/pcs | |||

| Insertion accuracy | ±0.05mm | |||

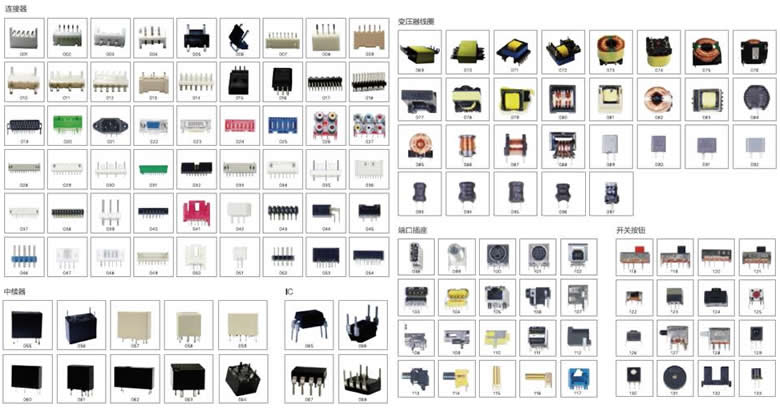

| Insertion species | resistor, capacitor, diode, triode, fuse, connector, relay, inductor, network connector, and other odd shape components etc. | |||

Clamping head | Picking method | Gripper /suction nozzle | ||

| Gripper quantity | Max 6 pcs | |||

| Max component size | W30*L38*H35mm | |||

| Insertion angle | flat, 0 degree. | |||

Feeder | Feeder type | tape feeder, tube feeder, tray feede, vibration feeder and other customized feeder | ||

| Feeder quantity | Max 16 feeders | |||

Utility | Working power supply | 1 Phase AC220V, 50HZ | ||

| Rated power | 2KW | |||

| Work pressure | 80 psi(0.5 Mpa) | |||

| Machine size | (W)1426x (D)1674 x (H)1500mm (not including light tower ) | |||

| Machine weight | About 900KG | |||

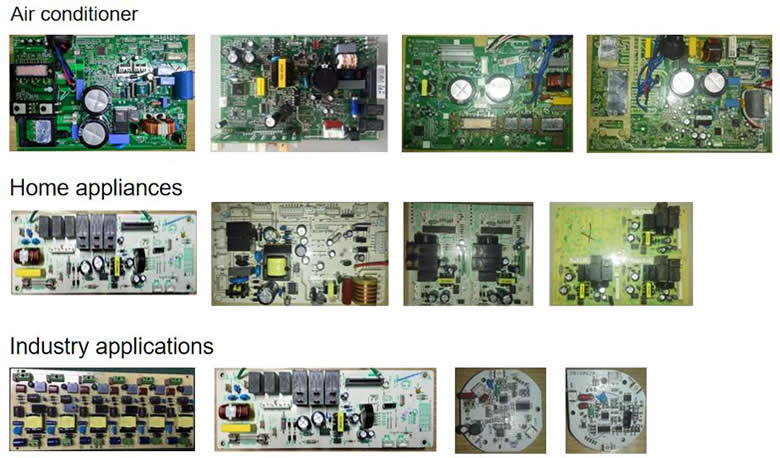

| Intelligent Component Insertion System AI-440 Application |

Application from our customers |

|

| Examples of possible Components |

|

0 review for Donec eu furniture

Related Products

Intelligent Component Insertion System AI-550

- Model: AI-550

Intelligent Pin Insertion System TI-750

- Model: TI-750

Intelligent Terminal Insertion System TI-880

- Model: TI-880

Add a review

Your email address will not be published. Required fields are marked