- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

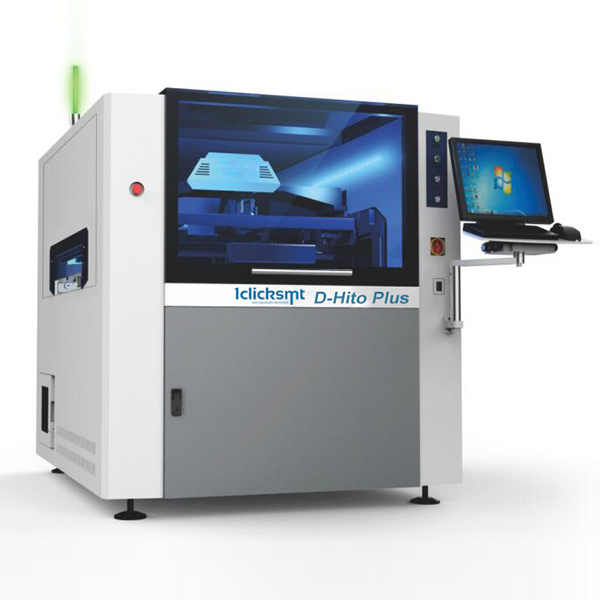

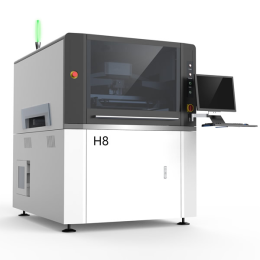

Automatic Screen Printer Machine D-Hito plus

Full automatic visual printing machine D-HITO PLUS Milestone, high precision customized product Product features: ▲The whole machine is fully controlled by servo system; ▲Automatic pressure feedback system; ▲Multifunctional image processing system;

Available Options

Automatic Screen Printer Machine D-Hito plus

×|

Automatic Screen Printer Machine D-Hito Plus Product Options Configuration: |

|

|

|

The rest of solder paste on the stencil monitoring system ● The solder paste inspection sensor before the scraper below remaining paste rolling diameter, intelligent prompt customers to join the solder paste. |

|

|

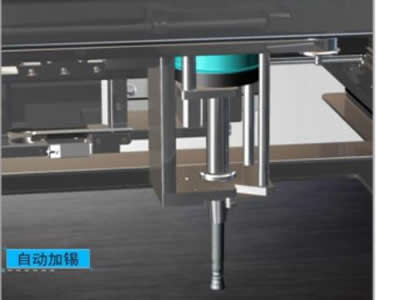

Automatic supply solder paste function ● General solder paste pot add directly ● Can be added at a fixed times ● Can be real-time monitoring the roll diameter of the solder paste on screen, trigger automatically add functionality |

|

|

Magnetic scraper ● The magnetic adsorption blade, replace the screw positioning, convenient and quick |

|

UPS power off protection ● After power off a certain time(10minutes)PC can keep the power supply, the protection of prduction data |

|

|

|

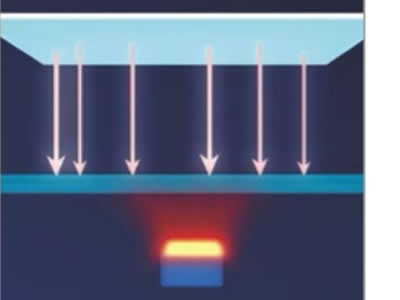

Intelligent temperature control system ● Temperature can be shown and adjustable on the overhead control system ● Temperature can be shown and adjustable on the external control system |

|

|

Stencil hole inspection ● Realization of plugging hole, hint whether clean steel net, steel net detect 2 consecutive failure, prompt the customer whether to replace cleaning mode, the frequency or manual cleaning. |

|

|

Industry 4.0 ● Production analysis and real-time statistical information function operation ● Alarm intelligent prompt system and processing solutions |

|

|

Automatic dispensing function ● It can realize dot, area filling the pount |

|

Manufacturing Execution System ● Custom different communication modes of customers and realize intelligent opertion management |

|

|

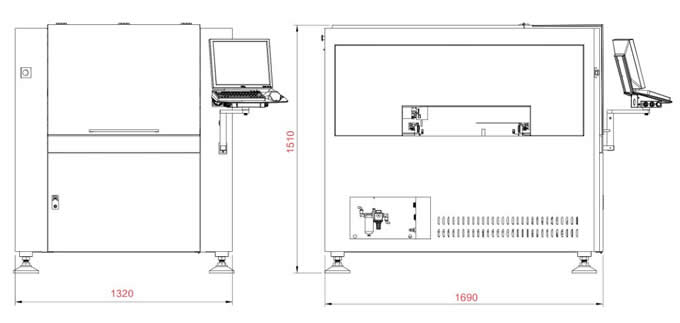

Automatic Screen Printer Machine D-Hito plus Product size : |

|

|

|

Automatic Screen Printer Machine D-Hito plus Specification : |

|

|

Model |

D-Hito plus |

|

Process Parameters |

Specification |

|

Printing Accuracy |

> 2Cpk@±20μm@,6☌ |

|

Repeat Position Accracy |

>2Cpk@±10μm@,6☌ |

|

Cycle Time |

7s |

|

Maximum Print Area |

510mm(X)×510mm(Y) |

|

Screen Frame Size |

470mm×370mm-750mm×750mm |

|

Screen Frame Thickness |

25mm-40mm |

|

Print Pressure |

0kg-10kg |

|

Ptint Speed |

1mm/sec-200mm/sec |

|

Print Gap |

0mm-20mm |

|

Substrate Separation |

Speed: 0.1mm/sec to 20mm/sec |

| Distance:0mm to 3mm | |

|

Separation option |

Separation after squeegee up; Squeegee up after separation |

|

Apply paste option |

Solder paste, printing ink, silver paste |

|

Transfer System |

Specification |

|

Belt Type |

U gear belt, front rail fixed |

|

ESD Compatibility |

Black transport belts and guides with surface resistivity of greater than 110Ω |

|

Width Adjustment |

Programmable motorized rear rail |

|

Transport Direction |

L→R,L→L,R→L,R→R |

|

Substrate Handling Size(Minimum) |

50mm(X)×50mm(Y) |

|

Substrate Handling Size(Maximum) |

510mm(X)×510mm(Y) |

|

Substrate Thickness |

0.4mm-6mm |

|

Substrate Weight(Maximum) |

≤ 3kg |

|

Substrate Warpage |

≤1% diagonal |

|

Substrate Fixture |

Flexible side clamp, Z to the wafer clamp device |

|

Substrate Underside Clearance |

≤25mm |

|

Vision |

Specification |

|

Multi function image process system |

Fiducial Mark software measurement, twice position, device identification function, Digital camera:1.3million pixels, the camera scene depth 2mm FOV:10*8mm |

|

Fiducial Recognition |

Automatic fiducial teach and find incorporating 0.1mm fiducial capture |

|

Fiducials |

Two or Four Fiducial marks Alignment System |

|

Fiducial Types |

□ spuare, ○ round, △ triangle, + cross, user-defined types |

|

Fiducial Size |

0.1mm-3mm |

|

Fiducial Locations |

Anywhere on substrate |

|

Fiducial Error Recovery |

Auto lighting adjustment |

| Auto fiducial search | |

|

Camera Lighting |

Automatic adjustment |

|

2D inspect system |

2D detect soldr printing quality |

|

Electrical configuration and environmental requirements |

Specification |

|

Voltage |

220Volts+/-10%. Single phase 50/60Hz |

|

Power |

3kw |

|

Air Supply |

0.45-0.6kg/cm² |

|

Temperature |

25±3℃ |

|

Humidity |

30%-70% relative humidity (non condensing) |

|

Certification |

Specification |

|

CE |

98/37/EC, 89-336/EEC, 73/23/EEC |

|

Acoustic Noise Level |

Less than 87dB |

|

Standatd Configuration |

Specification |

|

Printer Construction |

One piece optimized welded frame |

|

Machine Control |

Four control motion control card |

|

Operation System |

Windows XP, Win7(option) |

|

Operator Interface |

17" DELL display screen, keyboard and mouse and DESEN V2 software, display on the right hand side. |

|

Closed loop feedback system of squeegee pressure |

Program control and screw direct integration closed loop control |

|

Autmatic positioning module of stencil |

Put the stencil into the support frame, the squeegee automatically realizes the positioning of the stencil |

|

PCB Support positioning system |

support block, support pin, Free splicing type vacuum cavity |

|

Intelligent cleaning system |

The diffrent sizd of wipe paper can be used, less paper consumption, solvent agent control module |

|

Machine Iterface |

SEMI Input/Output 4 core internatiol standard interface |

|

Connectivity |

RJ-45LAN(networking)and USB2 interface available |

|

Three color intelligent LED warning light |

Programmable with audible alarm |

|

Documentation |

Hard coopy manuals comprising:Opeartor, Installation, and Electrical Drawings. On board technical manuals and tutorals supporting operator functions. |

|

Aoutomatic platform detection system |

The platform height is automticlly calibrated according to the thickness of the plate |

|

Intelligent closed-loop compensation platform |

UVW full servo platform, Shaft drive independent adjustment |

|

High performance and high precision platform |

The platform processing method adopts the annealing process and the knife quick milling method, and the residual of the metal stress in the platform is reduced. Easy deformation, precision assurance |

|

Approximate Dimensions |

1320(L)×1690(W)×1510(H)mm |

|

Approximate Weight |

1600kg boxed (dependent upon configured options selected wiht machine) |

| 1450kg unboxed (dependent upon configured options selected wiht machine) | |

|

Software & Communications |

Specification |

|

Software intelligent backup module |

Database automatic backup, software upgrade is not lost |

|

Maintenance early warning function |

Machine wire rod, slide block, motor and other automtic maintenance message |

|

Printing parameter intelligent module |

Customer select the type of production, like FPC, LED, Phone PCB the printer can give the parameter automatically. |

|

Recovery system of solder paste |

The fixed frequency to recovery the solder paste into the printing area. |

|

Handing & Cleaner Options |

Specification |

|

Substrate Handing Size(maximum) |

Long board options--maximum extend to 510*510mm, CCD scope biggest 510*510mm |

|

Under Stencil Cleaning |

Largest clean drops drench type 510mm size |

0 review for Donec eu furniture

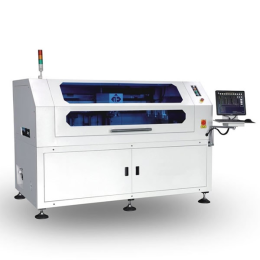

Related Products

Fully Automatic Screen Printer H12 & H15

- Model: H12 & H15

Thick Film Screen Printer Series

- Model: WZ-1202RS

Add a review

Your email address will not be published. Required fields are marked