- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

Double liquid Potting Machine DLP-400A

Gear pump for metering, screw pump is optional. Material loading by vacuum pump. Material agitating and deforming by vacuum pump. Metering ratio is adjustable. Metering accuracy :±3%. Dynamic mixing head. PLC and touch screen control. Full English interface.

Available Options

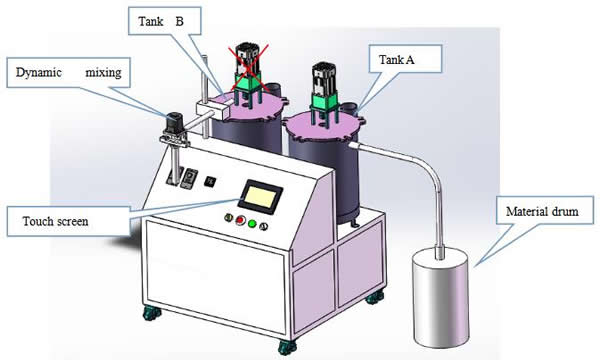

Double liquid Potting Machine DLP-400A

×|

Working principles of dual fluid potting machine: |

|

|

1. Vacuum pump suck material A, B from 5KG drum to the storage tank . |

|

|

2. Set the mixed proportion on the software. |

|

|

3. Material A, B metering by gear pump are delivered to mixing head. |

|

|

4. Mix material A/B with dynamic or static mode, so as to ensure an adequate mixing. |

|

|

5. Mixed material be potted into the product trough mixing tube. |

|

|

Details: |

|

|

|

|

|

1. Dynamic mixing head The tube mixer is driven by a mixing motor, so as to make the glue mixed uniformly |

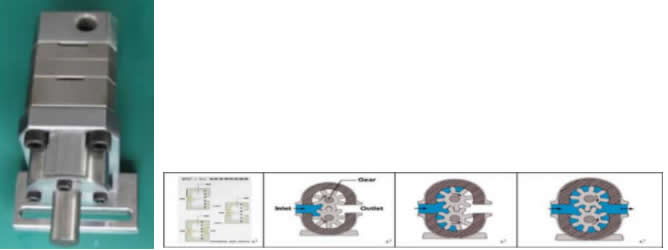

|

2.Gear pump 1.Stable pressure, not stirred by vortex flush. 2.Compact size, simply structure, easy for maintenance. 3.Controlled by precise step motor with high glue pumping accuracy. |

|

|

|

Features of the A B glue potting system : |

|

● The A B potting system adopt touch screen and PLC operating system. |

|

● Material A adopt gear pump for metering controlled by step motor. |

|

● Material B adopt gear pump for metering controlled by step motor. |

|

● Tank A is equipped with material agitating device to prevent precipitation. |

|

● Metering ratio is adjustable by required ratio ±10%. |

|

● Potting speed is adjustable. |

|

● A /B material mixing accuracy is ±3%. |

|

● Equipped with dynamic mixing driven by AC motor,or static mixing tube which can make a uniform potting process. |

|

● Equipped with vacuum pump for loading material and material deforming. |

|

● Equipped with 2L cleaning tank for valve and mixing tube cleaning. |

|

● Equipped with Pipe A/B pressure sensor to prevent exploding by high pressure. |

|

● Full English software, easy to operate. |

|

Parameters of the A/B glue potting part specification : |

|

|

Model |

DLP-400A |

|

Metering ratio |

Adjustable, required ratio ±10% |

|

Material A tank capacity |

15L, 25L |

|

Material B tank capacity |

15L, 25L |

|

Material A tank agitating |

Yes |

|

Material B tank agitating |

Optional |

|

Material A tank with hose heating |

Optional |

|

Material B tank with hose heating |

Optional |

|

Cleaning tank |

2L |

|

Material A metering |

Volume metering by gear pump or screw pump with step motor control |

|

Material B metering |

Volume metering by gear pump or screw pump with step motor control |

|

Mixing mode |

Dynamic mixing or static mixing |

|

Control mode |

PLC control |

|

Air supply |

0.4~0.7MPa |

|

Power supply |

1P, AC220V 50Hz |

|

Dimensions |

Approx 700L*650W*1100H(mm), the machine size might differ according to tank dimension |

|

Weight |

180kg |

|

Option: |

|

● Material A tank with hose heating. |

|

● Material B tank with hose heating. |

|

● Material B tank agitating. |

|

● GR-400S 3 axis dispensing platform. |

Add a review

Your email address will not be published. Required fields are marked