- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

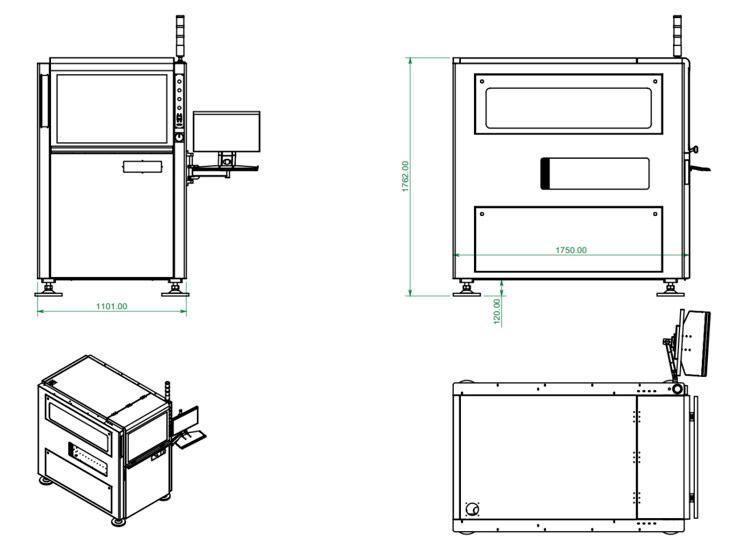

Falcon SA-510F SMT Component Automated Inspection System With Flipper

Falcon SA-510F is a Top AOI equipment for SMT component inspection and chip component inspection.The software adopts the function of image comparison for programming, which is simple to program, it greatly reduce the programming and debugging work.The machine is equipped with a flipper conveyor, and the PCB board can be flipped to detect the bottom.

Available Options

Falcon SA-510F SMT Component Automated Inspection System With Flipper

×

|

|

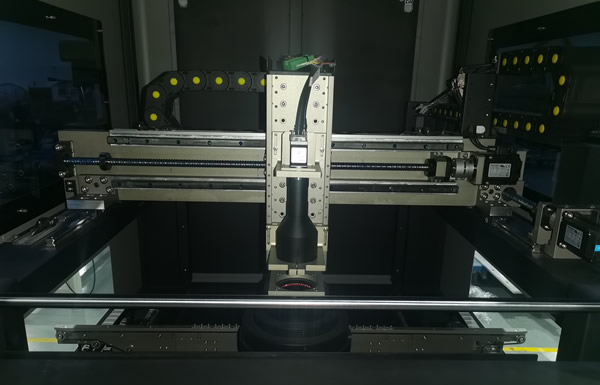

Hardware ● High stability platform ensure machine running fast and stably. |

|

|

Hardware ● X/Y servo motor with high precision ball screw driving system ensures running accuracy. |

|

|

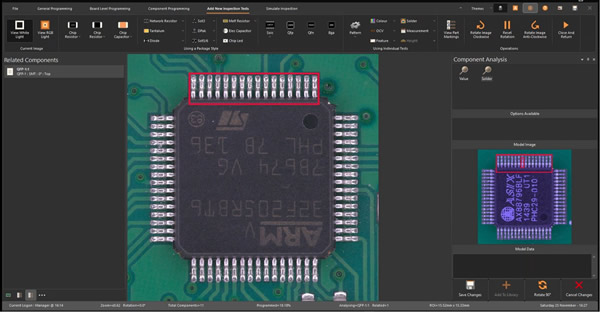

Hardware ● Equipped with 12M pixels CCD with RGB+W+UV 5 color light source to ensure inspection accuracy. |

|

|

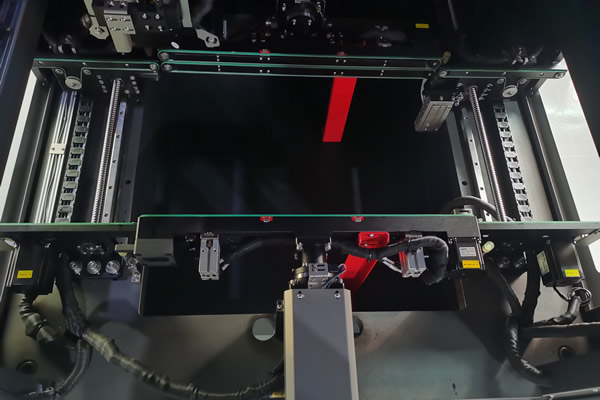

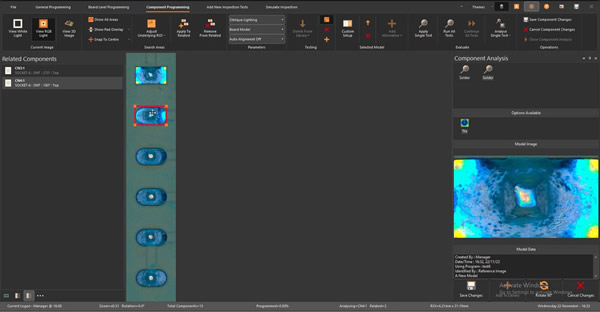

Hardware ● The machine is equipped with a flipper conveyor, and the PCB board can be flipped to detect the bottom.The machine uses a three-section adjustable width track to control PCB transportation, and is equipped with automatic positioning and automatic clamping devices to ensure accurate positioning of the PCB. |

|

|

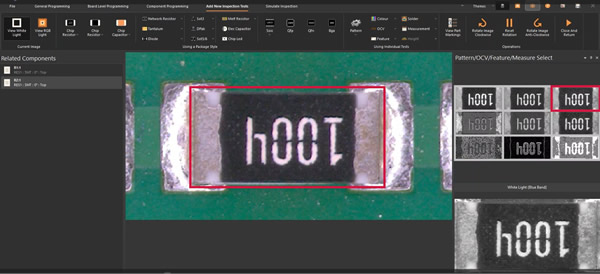

Algorithm Intelligent programming way: ● The traditional algorithm is mainly to compare the color of the reflected light of the soldering joint, and then to judge whether it has bad quality. In this case, the programmer is required to be experienced and familiar with the various forms of bad products. ● The software adopts the function of image comparison for programming, which is simple to program. |

|

|

Programming ● Easy programming:The machine has a library of components, and commonly used components can be programmed directly using the parameters in the library. |

|

|

Programming ● The system automatically matches the detection parameters of solder joints, No need to draw separate pin frames and solder frames, just draw the overall detection box of the solder pad, and the software will automatically identify the solder area and pins. |

|

|

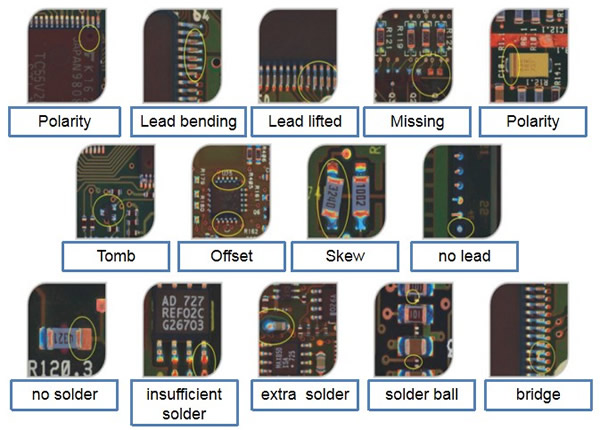

Detection item SMD Component Detection item: ● Missing, Reversed, Shift, Damaged, Skew, Redundant, Foreign material. |

|

|

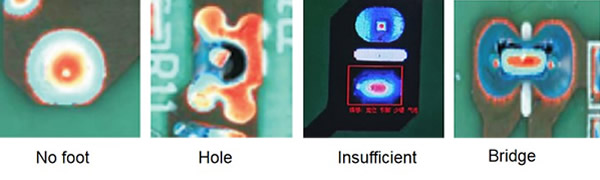

Detection item ● THT Solder Joint Detection item: excess, insufficient, no foot, bridge, hole etc. |

|

Falcon SA-510F SMT Component Automated Inspection System With Flipper Features |

|

● High stability platform ensure machine running fast and stably. |

|

● X/Y servo motor with high precision ball screw driving system ensures running accuracy. |

|

● Equipped with 12M pixels CCD with RGB+W+UV 5 color light source to ensure inspection accuracy. |

|

● Detection items: Chip components: Wrong, Miss, Reversed, Skew, Redundant, shift, foreign matter. Solder joint: excess, insufficient, no foot, bridge, not wetting. |

|

● The software adopts the function of image comparison for programming, which is simple to program, it greatly reduce the programming and debugging work.Support CAD file fast programming. |

|

● Equipped with Data statistics software, easy to search and export detailed statistical data. |

|

● Automatically read barcode with camera. |

|

● The machine is equipped with a flipper conveyor, and the PCB board can be flipped to detect the bottom. |

|

Falcon SA-510F SMT Component Automated Inspection System Specification: |

|

|

Model |

Falcon SA-510F |

|

Camera: |

Basler 12MP 5GigE Camera |

|

Lens Options: |

Standard: 15um, Optional 10um (Customisable Lens Options Available) |

|

Lighting: |

5 Colour Lighting Ring (RGBW/UV) |

|

X / Y Movement: |

AC Servo Motor Ball Screw and Linear Rail |

|

PC Configuration: |

Intel Core i5 Processor, 16GB DDR4 Memory, 1TB M.2 SSD |

|

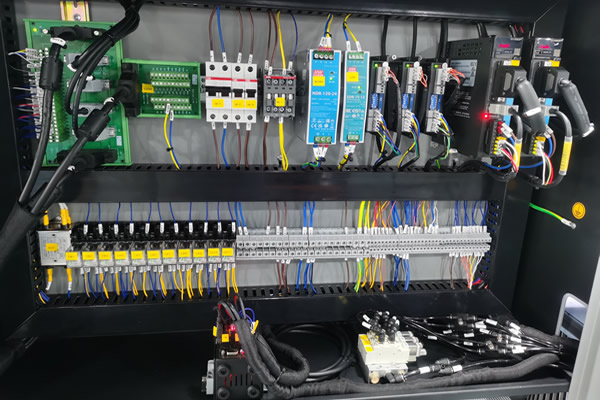

Power Supply: |

1P, 220V, 50/60Hz, 10A |

|

Machine Dimensions: |

1101mm x 1750mm x 1762mm (W x D x H) Excluding PC and three color lights |

|

Machine Weight: |

795Kg |

|

Operating System: |

Windows 11 64Bit |

|

Programming: |

CAD File Loading, Manual Teaching |

|

Statistic Data Function: |

Integrated SPC Software with Automatic Program Optimisation |

|

Minimum PCB Size: |

50mm x 50mm (L x W) |

|

Maximum PCB Size: |

510mm x 460mm (L x W) |

|

Maximum PCB Thickness: |

< 6.0mm |

|

Component Clearance: |

Top: 70mm, Bottom: 40mm |

|

Clamping Edge: |

> 3.0mm |

|

Component Inspection Tests : |

Missing, Reversed, Shifted, Damaged, Skew, Tombstone |

|

Solder Inspection Tests : |

No Solder, Insufficient/Extra Solder, Bridge |

|

Smallest Component Inspection: |

Chip: 0201 |

|

Barcode Recognition: |

1D or 2D Barcode Reading Via The Camera |

|

Conveyor: |

The machine is equipped with a flipper conveyor, and the PCB board can be flipped to detect the bottom |

|

Optional Stations: |

Offline Programming Station, Rework Station and Remote Review Station |

|

Software function |

|

Multiple detection and debugging modes: |

|

● Support panel board detection. |

|

● In a program, it can program both the A and B sides of the PCB simultaneously. |

|

● Online programming and debugging without stopping the production line. |

|

● Offline programming (optional). |

|

Falcon SA-510F SMT Component Automated Inspection System Includes: |

|

Standard configuration: |

|

1. Falcon SA-510F SMT Component Automated Inspection System. |

|

2. Online programming software (combined with AOI software). |

|

3. Data statistic software (combined with AOI software). |

|

|

|

Option configuration: |

|

1. Offline programming software. |

|

2. Repair station software |

0 review for Donec eu furniture

Related Products

Merlin A-400P Offline Automated Inspection System

- Model: Merlin A-400P

X-Ray Counter SoYi-C3

- Model: SoYi-C3

X-Ray Counter SoYi-C2

- Model: SoYi-C2

SA-500 SMT Component Automated Inspection System

- Model: SA-500

S-350/S-600 Series Desktop SPI Machine

- Model: S-350/600

Add a review

Your email address will not be published. Required fields are marked