- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

Full Automatic Solder Paste Printing Machine G9+

The G9+ automatic tin paste printing press is a high-end model for SMT high-end application, which can satisfy the printing process requirements of 03015, 0.25 pitch, high precision and high speed.

Available Options

Full Automatic Solder Paste Printing Machine G9+

×|

|

CCD digital camera system ● Total new optical path system, uniform circular light and high brightness of coaxial light source. With both light source system, brightness can adjust to an infinite loop, slowing different mark point can be easily recognize (induding uneven mark point) such as tin plating, copper plating, silver plating, hot air soldering, FPC and various types of different PCB color. |

|

|

Highly precise PCB thickness adjustment table ● Advance design, compact structure, high reliability, Smooth and stable lift up/down platform, pin height automatically adjust by software control. Precisely realize different types of PCB thickness position height adjust. |

|

|

Guide Rail positioning System ● New pattern patented guide rail can detachable, programmable flexible side clamp, specific to FPC, PCB warpage, perform a unique clamping plate device. Through software programming can automatically stretch out and draw back unaffected PCB thickness. |

|

|

Innovative squeegee structure design ● Adopt a comprehensive squeegee system which enhances stability and shelf-life. |

|

|

High speed stencil cleaning ● Downward dispensing deaning structure successfully prevents cfogged opening (which is always the root cause for ineffective cleaning) from taking place. The length of solvent dispensed can also be easily amended with software control. |

|

|

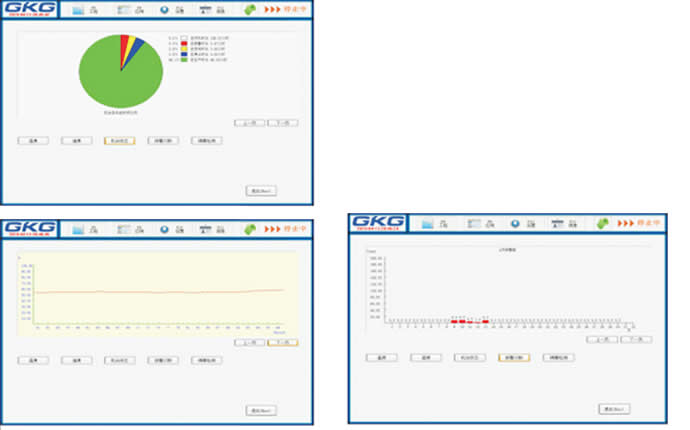

New multi-function interface ● Simplicity, Clearly understand, friendly user. ● Actual temperature and humidity monitor function. |

|

|

Stencil check System ● Through light source compensation at stencil and CCD real time inspection check on stencil holes which can rapidly detect, judge stend after deaning whether stencil holes is been block and auto dean. Is complement for PCB 2D inspection. |

|

|

Automatic Dispensing System ● In view of the different printing requirement, dispensing through glue, solderpaste, dispense Ine, padding etc can be performed after the printing process. Dispensing head te equip with heating function to maintain glue viscosity with better flowability. |

|

|

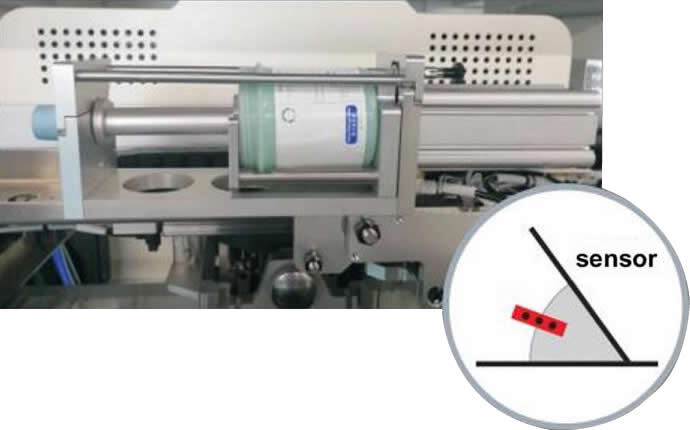

Cylindricallype automatic add solder and solder paste inspection Mion ● MobSe automatic add solder paste to ensure the qualty of solder paste and the amount of solder paste In sted mesh. To ensure the quality and productivity of customers. ● Closed looped system involving paste roling diameter monitoring and auto paste dispensing, creating an entirely smart and hassle free quality control technique. |

|

|

SPI Onlint ● With SPI dose loop connection, when received SPI feedback on poor printing Information, machine wil automatic adjust per SPI data and correct. XY shifted auto adjust complete by within 3 pieces and clean stencil This wil improve printing quaity and production efficiency. It form a complete printing feedback system. |

|

|

4.0 the compatibility ofleading industry ● Through to the machine status, parameters can be automatically upload or output support customer Industrial 4.0 intelligence production much more guarantee. With industrial 4.0 it can seamless connection and realized with customer MES system, product traceability, intelligence control machine maintenance. Distribution according to the on-site management implementation engineers at the level of access. |

|

|

BTB ● BTB provides greater flexibility for the user production line configuration, and now you can use G9+ BToB's excellent print performance to get dual channel output in less total area. |

|

Full Automatic Solder Paste Printing Machine G9+ Specification: |

|

|

Model |

G9+ |

|

Substrate processing |

|

|

Maximum board size: |

450*340mm |

|

Minimum board size: |

50*50mm |

|

Board thickness: |

0.4~5mm |

|

Camera Mechanical range: |

450*310mm |

|

Maximum board weight: |

3kg |

|

Board edge clearance: |

25mm |

|

Board height: |

15mm |

|

Transport speed: |

900 ± 40mm |

|

Transport speed: |

Segmented control, 1500mm/s (Max) Program Control |

|

Transport direction: |

One stage |

|

Board clamp: |

Automatic retractable pressing Paerted. Put on the top clan-phg |

| Side clamprig | |

| Adsorption function | |

|

Support System: |

Magnetic Pin |

| Support Block | |

| Manual up-doMi tabte | |

|

Printing Parameters |

|

|

Snap-off: |

0-20mm |

|

Print Mode: |

One/Twice |

|

queegee Type: |

0.5~20Kg |

|

Print Mode: |

One/Twice |

|

Queegee Type: |

Rubber/Squeegee Blade (angle 45/55/60) |

|

Print Speed: |

10~200mm/sec |

|

Print Pressure: |

0.5~10Kg |

|

The template frane size: |

470*370mm~737*737mm(thickness: 20-40mm) |

|

Cleaning System: |

Drops of ran type cleaning system |

| Reinforced Vacuum absorption | |

| Dry, Wet Vacuum three modes | |

|

Vision |

|

|

CCD FOV: |

10*8mm |

|

Fiducial maik types: |

Standard shape datum, custom images |

| Pad | |

| Hole | |

|

Camera System: |

Look up/down optics structure |

| CCDdigital camera | |

| Geomedy pattern match | |

|

Machine Performance |

|

|

Repeat Position Accuracy: |

±12.5um@6o, CPK>2.0 |

|

PrintAccuracy: |

±18um@6o, CPK>2.0 |

|

Based on the third party test system(CTQ)Verify the actual solder paste printing position repeat precision |

|

|

Cycle time: |

< 7.5sec |

|

Machine parameter |

|

|

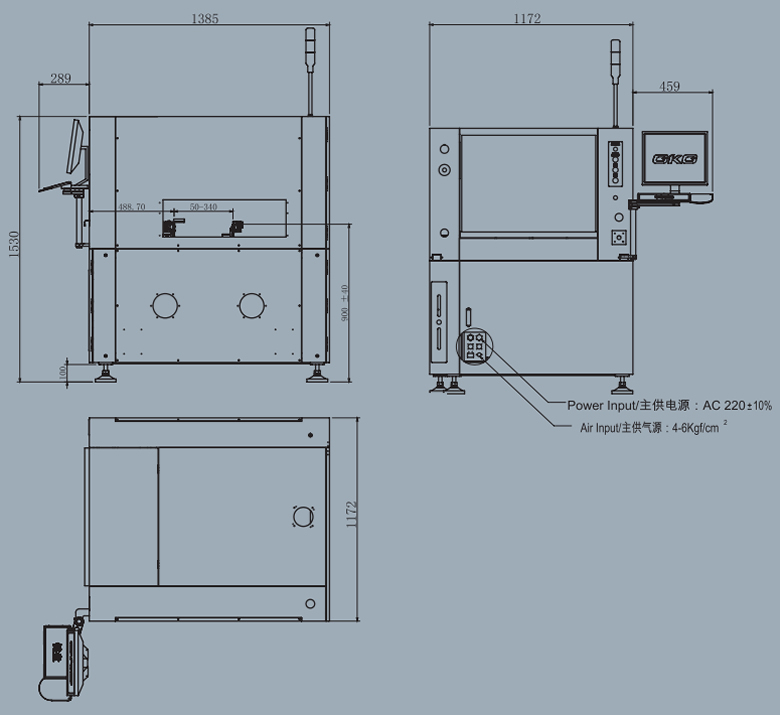

Power Source: |

AC:220 ±10%, 50/60HZ 2.5KW |

|

Air Pressure: |

4-6Kgf/cm2 |

|

Air Consumption: |

5L/min |

|

Operating Temperature: |

-20℃~+45℃ |

|

Working environment humidity: |

30%~60% |

|

Machine dimension (without Tower light): |

1530(H) mm |

|

Machine Length: |

1172(L) mm |

|

Machine Width: |

1385(W) mm |

|

Machine Weight Approx: |

Approx: 1000Kg |

0 review for Donec eu furniture

Related Products

Full Automatic Solder Paste Printing Machine GSE

- Model: GSE

Full Automatic Solder Paste Printing Machine GSK

- Model: GSK

Full Automatic Solder Paste Printing Machine K870

- Model: K870

Full Automatic Solder Paste Printing Machine GTS

- Model: GTS

Full Automatic Solder Paste Printing Machine GT++

- Model: GT++

Add a review

Your email address will not be published. Required fields are marked