- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

Single Station Benchtop Dispensing Machine GR-300S

The GR300S is an automated desktop type dispensing robot with a variety of dispensing valve and material feeding system to meet different material dispensing requirement.

Available Options

Single Station Benchtop Dispensing Machine GR-300S

×|

|

Built-in a fully-integrated dispensing controller with independent air regulator and suck back function. |

|||||||||||

|

|

Hand-held teach pendant with powerful software is easy for programming. |

|||||||||||

|

|

Virous valves with glue feeding system meet different fluid dispensing requirement, for examples: UV adhesive, EPOXY (black adhesive), white adhesive, SILICON, epoxy resin, grease, conformal coating fluid, and other kinds of fluid dispensing.

Application:310ml cartridge with GR-H25 valve for, grease and thermal conductive sillicon dispensing. |

|||||||||||

|

|

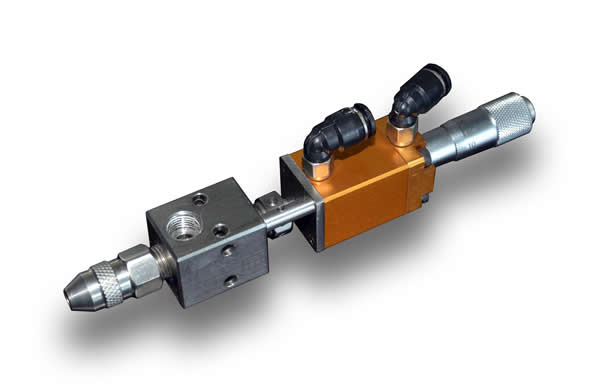

Micrometer high precision valve GR-D2121 Plunger structure, flow rate can be ajusted precisely by micrometer, small size and corrosion-resistant, it is suitable for UV glue, paint, oil etc. low viscosity, and good fluidity glue. |

|||||||||||

|

||||||||||||

|

|

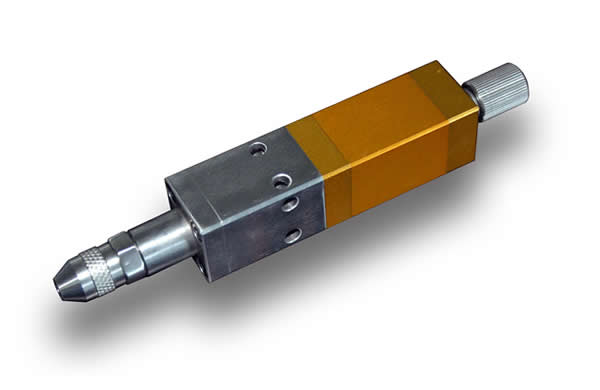

Adjustable precision valve GR-H2222 Plunger structure, small flow rate valve, flow rate can be ajusted, small size and corrosion-resistant, it is suitable for midium-high viscosity, and poor fluidity glue, such as silicon glue, epoxy glue, grease, red glue, etc. |

|||||||||||

|

||||||||||||

|

|

Suck back valve GR-H25 The GR-H25 Suck-Back Valve is designed to prevent extra protection against post-dispense dripping when dispensing medium to high viscosity liquids such as sillicon, grease, etc. |

|||||||||||

|

||||||||||||

|

|

V-1000 Coating thickness can be adjusted by changing air pressure and moving speed. Coating width can be adjusted by changing air pressure. V-1000 coating valve is applied to areas where: 1.most of coating. |

|||||||||||

|

||||||||||||

|

Single Station Benchtop Dispensing Machine GR-300S Features: |

|

● The GR300S is an automated desktop type dispensing robot with a variety of dispensing valve and material feeding system to meet different material dispensing requirement. |

|

● High quality step motor with high precision linear guide rail and it's driving system, ensure stable and precise run of motion system. |

|

● Machine can fit various quality dispensing valve which can meet different requirement. |

|

● Built in dispensing controller with independant air regulator. |

|

● Customized glue feeding system like cartridge with cylinder pusher, pressure tank, syringe with heating device is optional to meet different dispensing requirement. |

|

● handheld teaching pendant with powerful software, all english interface, easy to operate. |

|

● Powerful software has the painting point, straight line, multi line segment, three-dimensional arc (spatial arc), round, rectangular, runway, coating, automatic corner rounding, irregular 3D spline curve and other graphical elements; rich handmade teaching function and graphical preview function. |

|

● Powerful software has route copy and array copy fuction, park loaction setting function, coordinate offset correction function, different dispensing height and lifting height setting function, pause and continue running fuction etc. |

|

Single Station Benchtop Dispensing Machine GR-300S specification: |

|||||

|

Item |

Model | GR300S | GR300D | GR300S2Y | GR300D2Y |

|

Stroke(mm) |

Numberof Axis | 3 | 3 | 4 | 4 |

| (SingleheadX,Y,Z) | (DoubleheadX,Y,Z) | (SingleheadX,Y1,Y2,Z) | (DoubleheadX,Y1,Y2,Z) | ||

| X-aixs | 300 | 300 | 300 | 300 | |

| Y-aixs | 300 | 300 | 300 | 300 | |

| Z-aixs | 80 | 80 | 80 | 80 | |

|

Speed (mm/s) |

Zaixs | 2.5-250 | 2.5-250 | 2.5-250 | 2.5-250 |

| XYaixs | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | |

|

Repeatability(mm) |

Z-aixs |

±0.05mm |

±0.05mm |

±0.05mm |

±0.05mm |

|

Dimensions(mm) |

WxDxH |

550x640x660 |

550x640x660 |

850x650x660 |

850x650x660 |

|

Weight |

NetWeight |

50kg |

55kg |

80kg |

85kg |

|

Power source |

Voltage/Frequency | AC220V, singlephase, 50/60Hz | |||

| Capacity | 750W | 750W | 800W | 800W | |

|

Motor |

Type | Step motor | |||

| Operation | MicroStep | ||||

|

Programming |

Techingmethod | Hand-heldteachpendant, ManualDatainput | |||

| Motioncontrol | PTP, CP(3dimensionalstraightline/circulararcinterpolation) | ||||

| Programcapacity | 2G memory,100 programs or instruction ≤8000 | ||||

|

MaximumLoad |

X-YAxes:15Kg(33lbs.) ZAxis:6Kg(13lbs.) |

||||

|

WorkingTemperature |

0-40°C (32-104°F) |

||||

|

AirInput |

5Kg/cm² (approx.70psi) |

||||

|

4 Axis Benchtop Dispensing Machine includes: |

|

Standard configuration: |

|

● X/Y1/Y2/Z/ 4Axis dispensing Machine. |

|

● Handheld teaching pendant. |

|

Optional configuration: |

|

● Double dispensing head. |

|

● GR-H2222 presicion dispensing valve. |

|

● GR-D2121 presicion dispensing valve. |

|

● GR-H25 suck back valve. |

|

● V-1000 selective coating valve. |

|

● 310ml silicon cartridge with cylinder pusher. |

|

● 2L SUS pressure tank. |

|

● 5L SUS pressure tank. |

|

● Safety over |

|

● Fume extractor QBDX-1001 |

|

● Syringe heating device |

0 review for Donec eu furniture

Related Products

High Speed Dispensing Machine SD-450

- Model: SD-450

Ultra Speed Dispensing Machine JD-450

- Model: JD-450

Benchtop Dispensing Machine SD-400i

- Model: SD-400i

Double Station Benchtop Dispensing Machine GR-300S2Y

- Model: GR-300S2Y

5 Axis Benchtop Dispensing Machine GR-400B

- Model: GR-400B

Add a review

Your email address will not be published. Required fields are marked