- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

|

|

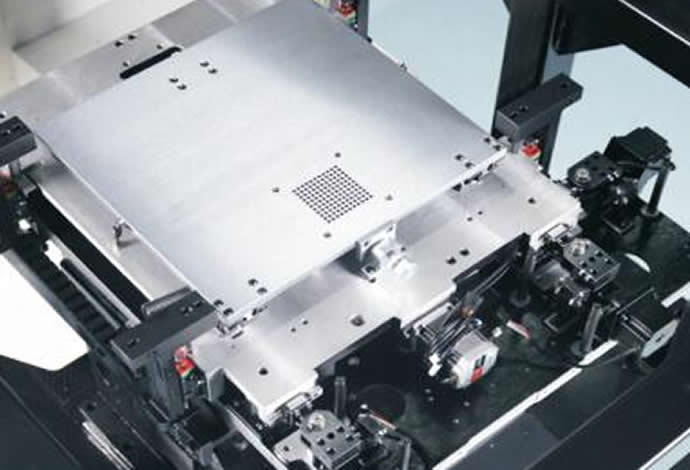

GKG special adjustment jacking platform ● Stable and easy to adjust, it can quickly adjust the pin jacking height of PCB with different thickness. |

|

|

Cleaning system ● GKG cleaning system equipped with three cleaning methods: dry cleaning, wetcleaning, vacuum. which can be combined to use. It can also be cleaned by manual if customer do not need to use automatic cleaning to reduce the cleaning time and improve production efficiency. The newly wiping system ensures full contact with the stencil, increased vacuum suction can effectively eliminate the remaining paste in the mesh, which can achieve effective automatic cleaning function. CCD part and cleaning system is separated, when CCD working, CCD part independently move to reduce the servo motor load and improve the machine speed and accuracy. |

|

|

Image and optical system ● Using uniform ring light and high brightness coaxial light, with promise brightness adjustment function, then all types of Mark points can be well recognized (Including therugged Markpoints), applicable for tin plating, coppering, goldplating, tinspraying, FPC andother types PCB with of different colors. With GKG patent mathematical model, able to ensure high accuracy. |

|

|

High adaptability steel mesh frame clamping system ● Able to print all kinds of size screen frames, and quickly change models during production line. |

|

|

Friendly Chinese/English operation interface ● Using Windows XP/win7 operation interface, with good man-machine dialogue function, and easy for operator quickly familiar with the operation especially when doing navigation effect of programming file. easy to s witch Chinese / English interface, with operation log, fault record / fault self-diagnosis / fault analysis prompt / light alarm and other functions. |

|

|

2D paste printing quality test and analysis ● Able to inspect shift, insufficient paste, missing and bridge and other defects to ensure the printing quality. |

|

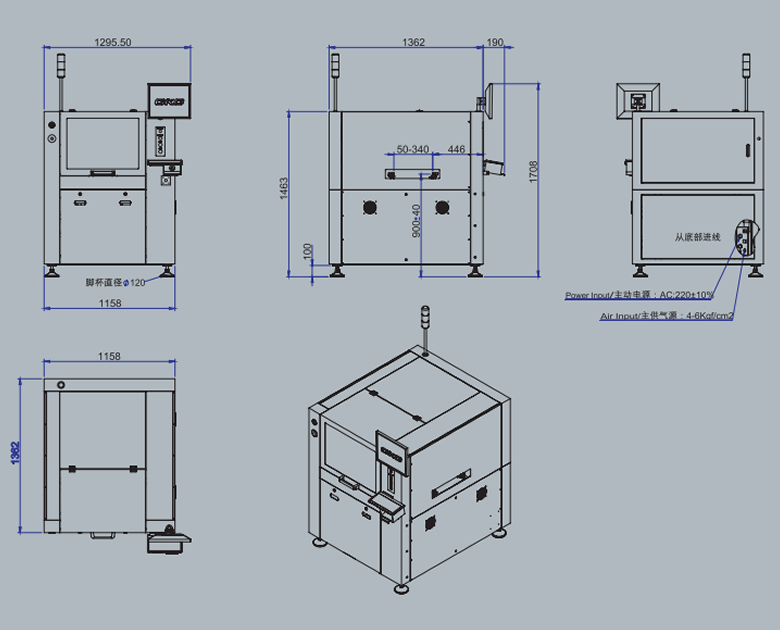

Full Automatic Solder Paste Printing Machine GSE Specification: |

||

|

Model |

GSE |

|

|

Screen Frames: |

Min Size | 370X370mm |

| Max Size | 737X737mm | |

| Thickness | 20~40mm | |

|

PCB Max Size: |

400X340mm | |

|

PCB Min Size: |

50X50mm |

|

|

PCB Thickness: |

0.4~6mm |

|

|

PCB Warpage: |

Max. PCB diagonal 1% |

|

|

Transport Height: |

900±40mm |

|

|

Transport Direction: |

L-R/R-L/L-L/R-R |

|

|

Transport Speed: |

1500mm/s(MAX), Program Control | |

|

Transport Height: |

One stage |

|

|

Conveyor Width adjustment: |

Auto | |

|

I/Ov Interface: |

SMEMA |

|

|

PCB Location: |

Support System | Magnetic Pin /SupportBlock manual Up-down table |

| Clamping System | Patented over the top clamping/side clamping | |

|

Print head: |

Two indep endent motorised print heads |

|

|

Squeegee Pressure: |

0.5~10Kg (Program Control) |

|

|

Print Speed: |

6-200mm/sec |

|

|

Print Mode |

One /Twice | |

|

Squeegee Type: |

Rubber /steel Squeegee Blade(Angle 45°/55°/60°) |

|

|

Cleaning System: |

Ireinforced vacuum absorption, dry, wet, vacuum three modes |

|

|

CCD FOV: |

8x6mm |

|

|

Adjustment: |

X: ± 3mm, Y:±7mm, θ: ± 2° |

|

|

Vision: |

Look Up/Down Optics Structure/CCD/Geometry Pattern-match |

|

|

Full Automatic Solder Paste Printing Machine GSE Specification: |

|

|

Model |

GSE |

|

Machine Performance |

|

|

Repeat Position Accuracy: |

±0.01mm |

|

Print Accuracy: |

±0.025mm |

|

Cycle Time: |

< 8 Sec |

|

Product Changeover: |

Old program : < 3 mins; New program set up: < 5 mins |

|

Air supply: |

4~6kgf/cm2 |

|

Power supply: |

AC:220±10%, 50/60HZ, 2.5KW |

|

Control Method: |

PC Control |

|

Operating system: |

Windows XP/Win7 |

|

Machine Dimensions: |

1158(L)x1362(W)x1463(H)mm |

|

Machine Weight Approx: |

Approx: 1000Kg |

0 review for Donec eu furniture

Related Products

Full Automatic Solder Paste Printing Machine G9+

- Model: G9+

Full Automatic Solder Paste Printing Machine GSK

- Model: GSK

Full Automatic Solder Paste Printing Machine K870

- Model: K870

Full Automatic Solder Paste Printing Machine GTS

- Model: GTS

Full Automatic Solder Paste Printing Machine GT++

- Model: GT++

Add a review

Your email address will not be published. Required fields are marked