- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

|

|

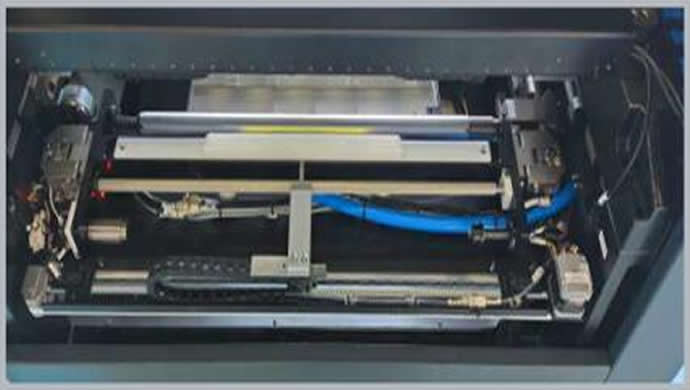

Drip cleaning system ● Drip cleaning structure, effectively prevent the solvent tube blockage cause no solvent while cleaning and poor cleaning effect. |

|

|

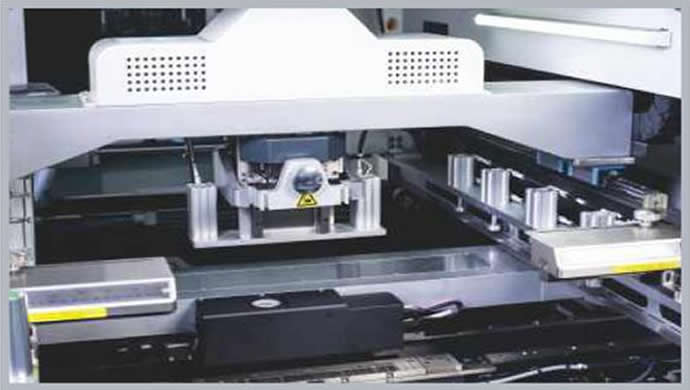

Total new squeegee blade structure design ● Through sliding rall and air cylinder new pattern squeogee blade structure, increase movement stability and prolonging the service life. |

|

|

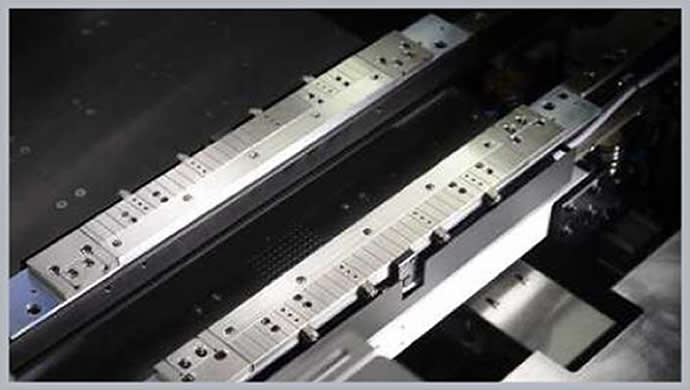

Guide Rail positioning System ● New pattern patented guide ral can datacheble, programmable flexible slde clamp, to FPC, PCB warpage, perform a unique clamping plate davice. Through software programming can automatically strefch out and draw back unaffected PCB thicknes. |

|

|

CCD digital camera system ● Total new opdcal path sysiem, uniform andd hich of coaxial light source. both light source system, brightness can adjust to an infinite loop, allowing different mark point can be easily recognize (including uneven mark point) such as tin plating, copper plating, silver plating, hot alr soldering, FPC and various types of different FCB color. |

|

|

High precision adjustable PCB thickness lift up platform ● Advance design, compact structure, high reliability, Smooth and stable lift up/down platform, pin height automatically adjust by software control. Precisely realize different types of PCB thickness position height adjust. |

|

|

New multi-function interface ● Simplicity, Clearly understand, friendly user. ● Actual temperature and humidity monitor function. |

| Cylindrical type automatic add solder and solderpaste inspectionfunction ● Mobile automatic add solder paste to ensure the quality of solder paste and the amount of solder paste in steel mesh. To ensure the quality and productivity of customers. ● Closed looped system involving paste rolling diameter monitoring and auto paste dispensing, creating an entirely smart and hassle free quality control technique. |

| Automatic Dispensing System ● In view of the different printing requirement, dispensing through glue, solderpaste, dispense line, padding etc can be performed after the printing process. Dispensing head is equip with heating function to maintain glue viscosity with better flowability. |

| SPIOn line ● With SPI close loop connection, when received SPI feedback on poor printing information, machine will automatic adjust per SPI data and correct. XY shifted auto adjust complete by within 3 pieces and clean stencil. This will improve printing quality and production efficiency. It form a complete printing feedback system. |

| Stencil check System ● Through light source compensation at stencil and CCD real time inspection check on stencil holes which can rapidly detect, judge stencil after cleaning whether stencil holes is been block and auto clean. Is complement for PCB 2D inspection. |

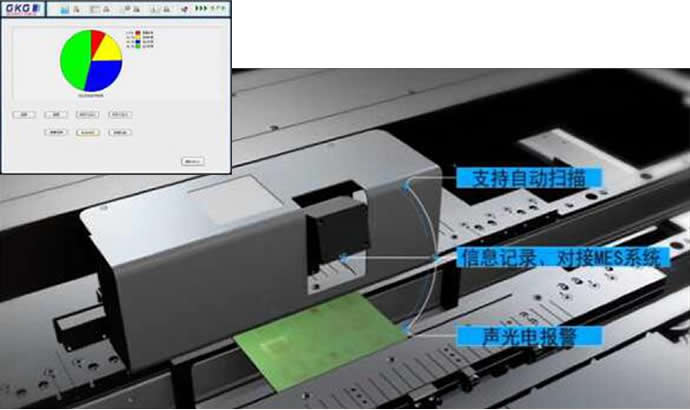

| 4.0 the compatiliility of leading industry ● Through to the machine status, parameters can be automatically upload or output support customer Industrial 4.0 intelligence production much more guarantee. With industrial 4.0 it can seamless connection and realized with customer MES system, product traceability, intelligence control machine maintenance. Distribution according to the on-site management implementation engineers at the level ofaccess. |

| BTB ● Double track performance: Two devices can be kept separately, such as running different products on each track. The two devices can be separated at any time. |

|

Full Automatic Solder Paste Printing Machine GT++ Specification: |

|

|

Model |

GT++ |

|

Machine Performance |

|

|

Repeat Position Accuracy: |

±10um@6o, CPK>2.0 |

|

PrintAccuracy: |

±17um@6o, CPK>2.0 |

|

NCP-CT: |

<7.5 sec |

|

HCP-CT: |

18s/pcs |

|

Process CT: |

4min |

|

Change over CT: |

2min |

|

Substrate processing parameter |

|

|

Maximum board size: |

510*510mm (Optional: 610*510mm) |

|

Minimum board size: |

50*50mm |

|

Board thickness: |

0.4~6mm |

|

Camera Mechanical range: |

590*510mm |

|

Maximum board weight: |

5kg |

|

Board edge clearance: |

2.5mm |

|

Board height: |

25mm |

|

Transport speed: |

900 ± 40mm |

|

(Max) Transport speed: |

Segmented control, 1500mm/s (Max) |

|

Transport direction: |

One stage |

|

Transmission direction: |

Left to right |

| Right to Left | |

| In and out the same | |

|

Support System: |

(65mm)Magnetic Pin |

| (65mm)Support Block | |

| Patented over the top clamping | |

|

Board clamp: |

Automatic top clamping |

| Side clamping | |

| Adsorption function | |

|

Printing Parameters |

|

|

Print Speed: |

10~200mm/sec |

|

Print Pressure: |

0.5~20Kg |

|

Print Mode: |

One/Twice |

|

Queegee Type: |

Rubber/Squeegee Blade (angle 45/55/60) |

|

Snap-off: |

0-20mm |

|

Snap-Speed: |

0-20mm/sec |

|

The template frame size: |

470*370mm~737*737mm |

|

Steel mesh positioning mode: |

Automatic Y orientation |

|

Cleaning Parameters |

|

|

Cleaning System: |

Dry, Wet Vacuum three modes |

|

High speed cleaning: |

Integrated & weave cleaning |

|

Cleaning system: |

Side spray type |

|

Cleaning stroke: |

Automatic generation |

|

Cleaning position: |

Post cleaning |

|

Cleaning Speed: |

10-200mm/sec |

|

Cleaning fluid consumption: |

Auto & Manually adjustable |

|

Cleaning paper consumption: |

Auto & Manually adjustable |

|

Vision Parameters |

|

|

CCD FOV: |

10*8mm |

|

Camera type: |

130 Thousand CCD Digital camera |

|

Camera System: |

Lock up/down optics structure |

|

Camera Cycle time: |

100ms |

|

Fiducial mark types: |

Standard Fiducial Mark Shape |

| round、square、diamonds cross | |

| Pad and profile | |

|

Mark size: |

0.1-6mm |

|

Mark number: |

Max: 4pcs |

|

Stay away number: |

Max: Ipcs |

|

Machine parameter |

|

|

Power Source: |

AC:220 ±10%, 50/60HZ 2.2KW |

|

Air Pressure: |

4~6Kgf/cm2 |

|

Air Consumption: |

5L/min |

|

Operating Temperature: |

-20℃~+45℃ |

|

Working environment humidity: |

30%~60% |

|

Machine dimension (without Tower light): |

1500(H) mm |

|

Machine Length: |

1240(L) mm |

|

Machine Width: |

1410(W) mm |

|

Machine Weight Approx: |

Approx: 1100Kg |

|

Equipment load bearing requirements: |

650Kg/㎡ |

0 review for Donec eu furniture

Related Products

Full Automatic Solder Paste Printing Machine G9+

- Model: G9+

Full Automatic Solder Paste Printing Machine GSE

- Model: GSE

Full Automatic Solder Paste Printing Machine GSK

- Model: GSK

Full Automatic Solder Paste Printing Machine K870

- Model: K870

Full Automatic Solder Paste Printing Machine GTS

- Model: GTS

Add a review

Your email address will not be published. Required fields are marked