- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

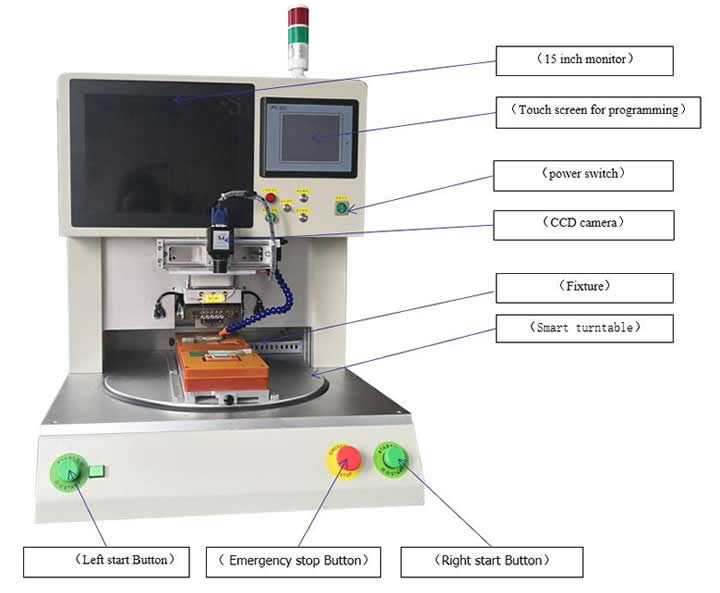

Rotating disc Hot Bar Soldering Machine HBS-2AM

HBS-2AM Hot Bar Soldering Machine use thermode technology that based on repid reflow by pluse heating to effectively solder flexible board on the PCB. Real time display on the touch screen. Can use CCD+displayer can accurate positioning and soldering quality check. The Z axis is controlled by a stepper motor and can be preset to soldeing pressure. Rotating double soldering stations with high soldering efficiency.

Available Options

Rotating disc Hot Bar Soldering Machine HBS-2AM

×

|

Rotating disc Hot Bar Soldering Machine HBS-2AM Features: |

|

1.For different products, heating speed can be adjusted |

|

2.With vacuum suction function, it is easier to adjust the fixture |

|

3.Microcomputer control, accurate and stable |

|

4.Programmable curve including preheat and reflow soldering temperatures |

|

5.Suitable for high density TAB, TCP pressing and FPC, FFC and PCB soldering |

|

6.Adopt precise PID control, phase Angle replace pulse drive |

|

7.Small vibration, low noise, no fluctuation of voltage |

|

8.Real time display temperature curve and temperature data |

|

9.Touch screen input data, simplify operation |

|

10.Rotating platform with precision motor control, accurate and stable |

|

11.In the software with digital pressure meter, can be preset pressure range.The Z axis use precise step motor.Position adjustment is very convenient. |

|

12.With pressure detection function, it automatically detects and adjusts the pressure to solve the problem of uneven force. We will replace the Z axis with a servo motor.(Option) |

|

Rotating disc Hot Bar Soldering Machine HBS-2AM specification : |

|||

|

1 |

Machine dimension Size |

L800*W720*H800mm | |

|

2 |

Working Area |

Max 180*200mm *2pcs | |

|

3 |

Weight |

Around 95kg | |

|

4 |

Air |

0.5~0.80 Mpa | |

|

5 |

Power |

AC220V±10%50HZ.2000W | |

|

6 |

Temperature setting |

3section | |

|

7 |

Work Environment | 10~60℃,40%~95% | |

|

8 |

Soldering Pressure | 1~100N | |

|

9 |

Soldering Pressure Precision value | ±1N | |

|

10 |

Temperature Setting | RT∽500℃, (±2℃) | |

|

11 |

Heating Rate | 250℃/s | |

|

12 |

Soldering Time |

1-99.9S | |

|

13 |

Soldering Precision | Pitch 0.2mm | |

|

14 |

Soldering Head Size | Max 50*3mm (or customized) | |

|

15 |

Soldering Head Flatness | ±0.02mm | |

|

16 |

Soldering Pin Range | >0.2mm | |

|

17 |

Contraposition Mode | CCD+ Display | |

|

18 |

Positioning Fixture |

2pcs | |

|

19 |

Material Placement Method | Manually | |

|

20 |

Start Mode | Start buton | |

|

21 |

Heating Mode | Pulse heating, the rise time is 1~2S | |

|

22 |

Platform Mode | Rotating Platform | |

|

23 |

Platform Control | Precision motor control,Precision value<0.02mm | |

|

24 |

Soldering Pressure Output | Motor Drive (closed-loop control) | |

|

Rotating disc Hot Bar Soldering Machine HBS-2AM Configuration: |

||

|

Item |

Main configuration name |

Place of origin |

|

1 |

Precision reducer |

Taiwan |

|

2 |

Rotary motor |

Precision stepper motor / Panasonic servo |

|

3 |

Rotary drive |

Stepper drive / Panasonic servo |

|

4 |

ZL press motor / push down drive |

Precision stepper motor / Panasonic servo |

|

5 |

Linear Guides |

Taiwan silver |

|

6 |

screw rod |

TBI |

|

7 |

Photoelectric Sensors | Omron |

|

8 |

Pulse transformer | customized |

|

9 |

System controller | Self development |

|

10 |

Switching power supply | Taiwan Ming weft |

|

11 |

Motor drive power | customized |

|

12 |

Liquid crystal display |

/ |

|

13 |

CCD | / |

|

14 |

The pressure regulating valve | Airtic |

|

15 |

Solenoid valve | Airtic |

|

16 |

Precision adjusting knob | / |

|

17 |

Button | schneider |

| Rotating disc Hot Bar Soldering Machine HBS-2AM Application : |

|

Advantages: ultra-fine spacing welding can be achieved; Digital temperature display; Soldering speed 3-5s |

|

Suitable for : |

|

1.FPC-PCB soldering |

|

2.FPC-FPC soldering |

|

3.FPC- ceramic wafer soldering |

|

4.FPC- ink cartridge plus chip soldering |

| Application |

|

|

Rotating disc Hot Bar Soldering Machine HBS-2AM Standard configuration : |

|

● Hot Bar Soldering Machine |

|

● Start button*1pcs |

|

● CCD+disply *1set |

|

● Air pipe*1pcs |

|

● 1 year parts warranty |

|

Rotating disc Hot Bar Soldering Machine HBS-2AM Optional configuration : |

|

● Customized precision fixture |

|

● Customized Soldering tip |

|

● Start button |

|

● Emergency Stop button |

|

● Power switch button |

|

● Z-axis pressure automatic detecting device (With pressure detection function, it automatically detects and adjusts the pressure to solve the problem of uneven force) |

0 review for Donec eu furniture

Related Products

Hot Bar Soldering Machine HBS-4AT

- Model: HBS-4AT

Hot Bar Soldering Machine HBS-A3

- Model: HBS-A3

Double Station Hot Bar Soldering Machine HBS-4AM

- Model: HBS-4AM

Precise resistance soldering machine WZ-04LB

- Model: WZ-04LB

Add a review

Your email address will not be published. Required fields are marked