- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

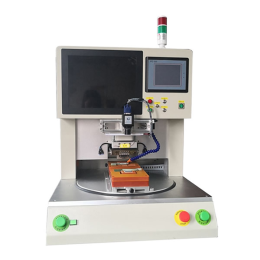

Hot Bar Soldering Machine HBS-4AT

HBS-4AT Hot Bar Soldering Machine use thermode technology that based on repid reflow by pluse heating to effectively solder flexible board on the PCB. Real time display on the touch screen. Can option CCD+displayer can accurate positioning and soldering quality check.The Z axis is controlled by a stepper motor and can be preset to soldeing pressure

Available Options

Hot Bar Soldering Machine HBS-4AT

×|

Hot Bar Soldering Machine HBS-4AT Features: |

|

1. The heating rate is customized to meet different products. |

|

2. Molybdenum alloy head to ensure temperature stability, fast heating speed and long service life. |

|

3. The level of soldering head is adjustable, to ensure uniform part assembly processing. |

|

4. Digital display to control temperature, easy and clear. |

|

5. In the software with digital pressure meter, can be preset pressure range.The Z axis use precise step motor. Position adjustment is very convenient. |

|

6. The soldering head is made of molybdenum alloy, with fast heating and long life time. |

|

7. It is equipped with precise PID control, phase Angle instead of pulse drive. |

|

8. Little vibration, low noise, no voltage fluctuation. |

|

9. Molybdenum alloy soldering head instead of traditional titanium alloy, heating faster, good coefficient of heat transfer, wear-resisting. |

|

10. The height is controlled by the motor, the z-axis adjustment precision is high, the pressure of soldering tip is even. |

|

11. Optional CCD with camera can assist the alignment pad of the product and observe the effect of soldering. |

|

Hot Bar Soldering Machine HBS-4AT specification : |

|

|

Model |

HBS-4AT |

|

Soldering platform movement method |

manual movement |

|

Way of starting |

foot switch |

|

Soldering head size |

MAX 60*5mm(Or customized) |

|

Minimum soldering pitch |

0.2mm |

|

power |

AC220V±10% 50HZ,2300W |

|

Soldering time |

1~99.9s adjustable |

|

Work pressure |

0.45-0.70Mpa |

|

Temperature setting |

RT~500 ± 5 DEG C |

|

Machine weight |

35kg |

|

Soldering pressure |

1~20kg |

|

Work size |

Max 150*150mm |

|

Work environment |

10-60℃ |

|

Machine Size |

440*440*530mm |

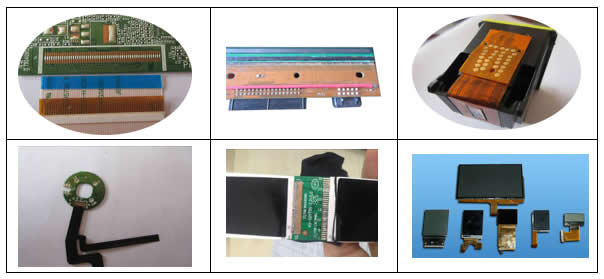

| Hot Bar Soldering Machine HBS-4AT Application : |

|

Advantages: ultra-fine spacing soldering can be achieved; Digital temperature display; Soldering speed 3-5s |

|

Suitable for : |

|

1.FPC-PCB soldering |

|

2.FPC-FPC soldering |

|

3.FPC- ceramic wafer soldering |

|

4.FPC- ink cartridge plus chip soldering |

| Application |

|

|

Hot Bar Soldering Machine HBS-4AT Configuration: |

|

1. Pressing module: stepper motor + screw |

|

2. Pressure display table: pointer |

|

3. Magnetic cylinder sensor switch: SMC |

|

4. Solenoid valve: made in Taiwan |

|

5. Connectors and trachea: made in Taiwan |

|

6. Filter regulator: made in Taiwan |

|

7. Precision cylinder under pressure regulator: SMC |

|

8. Control system: independent research and development ( Chinese ) |

|

9. Power transformer: 220V, 2000W |

|

10. Driver module: 45A |

|

11. Vacuum Generators: SMC |

|

12. Button switch: Schneider |

|

13. Relay:Omron |

|

14. Chassis components: aluminum plus bending parts |

|

15. Body color: gray |

|

Hot Bar Soldering Machine HBS-4ATStandard configuration: |

|

● Hot Bar Soldering Machine |

|

● Start button*1pcs |

|

● Air pipe*1pcs |

|

● 1 year parts warranty |

|

Hot Bar Soldering Machine HBS-4AT Optional configuration: |

|

● Customized precision fixture. |

|

● Customized Soldering tip |

|

● CCD +displayer 1set |

|

● Start button |

|

● Emergency Stop button |

|

● Power switch button |

0 review for Donec eu furniture

Related Products

Hot Bar Soldering Machine HBS-A4

- Model: HBS-A4

Hot Bar Soldering Machine HBS-A3

- Model: HBS-A3

Double Station Hot Bar Soldering Machine HBS-4AM

- Model: HBS-4AM

Precise resistance soldering machine WZ-04LB

- Model: WZ-04LB

Add a review

Your email address will not be published. Required fields are marked