- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

IR Panel curing oven

The In-line Curing Machine (IR Series) is ideal for high-volume curing production. They are easy tp integrate with different Conformal Coating machines. Available in different lengths, they provide the flexibility to match your production requirements. Also with robust construction and a streamlined appearance.

Available Options

IR Panel curing oven

×|

● The cure chamber achieves a thermally uniform atmosphere with Japan designed Far IR Panel. |

||||||||||||||||||||||

|

||||||||||||||||||||||

|

● Far IR Panel specially designed for coating process, high IR to heat exchange ratio, 100mm distance to IR panel surface can meet 50--250c degree. For IR tube, it can meet 50--200c degree. ● Benefit from the high IR/heat exchange ratio (0.9--0.95), with same target temperature to PCB, the heater can save 30--50% electrical power compare with IR tube. Meanwhile, because of smaller heater power, heater can get long life time. Usually it is no problem for 5 years. |

||||||||||||||||||||||

|

|

||||||||||||||||||||||

|

● IR panel surface with special water-proof treatment, when coating material need higher humidity to curing, heater can stand it too. |

||||||||||||||||||||||

|

||||||||||||||||||||||

|

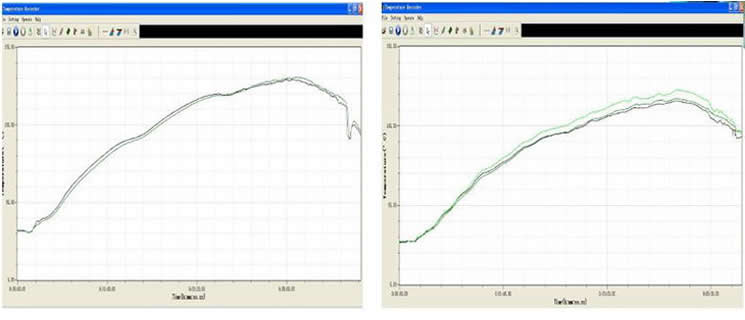

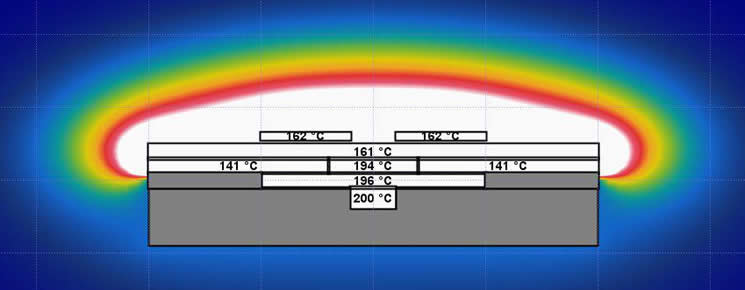

● Temperature Profile Comparison with IR Panel and Tube. ● Setting Temperature 200C. |

||||||||||||||||||||||

|

||||||||||||||||||||||

|

● Energy consumption comparison list. |

||||||||||||||||||||||

|

|

||||||||||||||||||||||

|

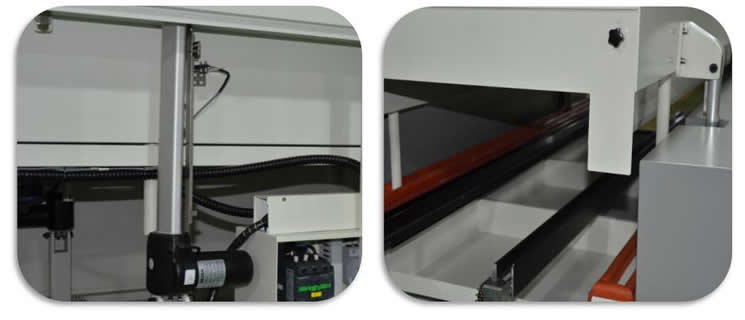

● The inner tunnel of the oven is made of stainless steel which easy for cleans. ● Specially enlarged the heat-resistant layer to 50mm, prevent the heat lose effectively, so to save energy lose. ● with electrical pole for oven tunnel & upper cover lifting. No need air source. |

||||||||||||||||||||||

|

||||||||||||||||||||||

|

IR-2030P Series Curing Oven Specification |

|

|

Item |

IR-2030P |

|

Dimension and Weight- IR-2030P |

|

|

Dimension L*W*H |

L2000mm*W1135mm*H1145mm |

|

Weight |

Approx.500kg |

|

Transport System |

|

|

Transport Height |

900±20mm |

|

Transport Speed |

0.1-3.5m/min |

|

Transport Direction |

L-R |

|

Transport Motor |

AC220V 90W |

|

Transport Mode |

Pin Chin (35B 5mm Stainless Steel) |

|

Width Adjustment |

MAX 450mm |

|

Heating System |

|

|

Heating Mode |

IR Panel (optional with IR Tube) |

|

Heating Zones |

3 Sets (Top 3, Bottom 3 is an option) |

|

Temperature Scope |

Room temp to 150℃ (IR Tube), Room temp to 250℃ (IR Panel ) |

|

Temperature Rising Time |

8 mins( To 150℃) (for IR Tube), 15 mins(To 250℃) (for IR Panel) |

|

PCB Size |

MAX W450*L450 |

|

PCB Clearance |

Top Side 60MM Bottom Side 60MM |

|

Control System |

|

|

Control Mode |

Touchscreen |

|

Power Supply |

AC380V |

|

Total Power |

10KW |

|

Running Power |

Top only (6-8kw for IR tube, 2--4KW for IR panel) |

|

Cover Lifting Mode |

Electric Screws |

|

IR-2033P Series Curing Oven Specification |

|

|

Item |

2033P |

|

Dimension and Weight-IR-2033P |

|

|

Dimension L*W*H |

L2000mm*W1135mm*H1145mm |

|

Weight |

Approx.570kg |

|

Transport System |

|

|

Transport Height |

900±20mm |

|

Transport Speed |

0.1-3.5m/min |

|

Transport Direction |

L-R |

|

Transport Motor |

AC220V 90W |

|

Transport Mode |

Pin Chin (35B 5mm Stainless Steel) |

|

Width Adjustment |

MAX 450mm |

|

Heating System |

|

|

Heating Mode |

IR Panel (optional with IR Tube) |

|

Heating Zones |

3 Sets (Top 3, Bottom 3) |

|

Temperature Scope |

Room temp to 150℃ (IR Tube), Room temp to 250℃ (IR Panel ) |

|

Temperature Rising Time |

8mins(To 150℃) (for IR Tube), 15mins(To 250℃) (for IR Panel) |

|

PCB Size |

MAX W450*L450 |

|

PCB Clearance |

Top Side 60MM Bottom Side 60MM |

|

Control System |

|

|

Control Mode |

Touchscreen |

|

Power Supply |

AC380V |

|

Total Power |

10KW |

|

Running Power |

Top only (6-8kw for IR tube, 2--4KW for IR panel) |

|

Cover Lifting Mode |

Electric Screws |

|

IR-2640P Series Curing Oven Specification |

|

|

Item |

2640P |

|

Dimension and Weight-IR-2640P |

|

|

Dimension L*W*H |

L2600mm*W1135mm*H1145mm |

|

Weight |

Approx.650kg |

|

Transport System |

|

|

Transport Height |

900±20mm |

|

Transport Speed |

0.1-3.5m/min |

|

Transport Direction |

L-R |

|

Transport Motor |

AC220V 90W |

|

Transport Mode |

Pin Chin (35B 5mm Stainless Steel) |

|

Width Adjustment |

MAX 450mm |

|

Heating System |

|

|

Heating Mode |

IR Panel (optional with IR Tube) |

|

Heating Zones |

4 Sets (Top4 , Bottom 4) |

|

Temperature Scope |

Room temp to 150℃ (IR Tube), Room temp to 250℃ (IR Panel ) |

|

Temperature Rising Time |

8 mins( To 150℃) (for IR Tube), 15mins(To 250℃) (for IR Panel) |

|

PCB Size |

MAX W450*L450 |

|

PCB Clearance |

Top Side 60MM Bottom Side 60MM |

|

Control System |

|

|

Control Mode |

Touchscreen |

|

Power Supply |

AC380V |

|

Total Power |

13.5KW |

|

Running Power |

Top only (7-10kw for IR tube, 5--8KW for IR panel) |

|

Cover Lifting Mode |

Electric Screws |

|

IR-2644P Series Curing Oven Specification |

|

|

Item |

2644P |

|

Dimension and Weight-IR-2644P |

|

|

Dimension L*W*H |

L2600mm*W1135mm*H1145mm |

|

Weight |

Approx.800kg |

|

Transport System |

|

|

Transport Height |

900±20mm |

|

Transport Speed |

0.1-3.5m/min |

|

Transport Direction |

L-R |

|

Transport Motor |

AC220V 90W |

|

Transport Mode |

Pin Chin (35B 5mm Stainless Steel) |

|

Width Adjustment |

MAX 450mm |

|

Heating System |

|

|

Heating Mode |

IR Panel (optional with IR Tube) |

|

Heating Zones |

4Sets (Top 4, Bottom 4) |

|

Temperature Scope |

Room temp to 150℃ (IR Tube), Room temp to 250℃ (IR Panel ) |

|

Temperature Rising Time |

8mins(To 150℃) (for IR Tube), 15mins(To 250℃)(for IR Panel) |

|

PCB Size |

MAX W450*L450 |

|

PCB Clearance |

Top Side 60MM Bottom Side 60MM |

|

Control System |

|

|

Control Mode |

Touchscreen |

|

Power Supply |

AC380V |

|

Total Power |

26KW |

|

Running Power |

Top & bottom (18--20kw for IR tube, 10--13KW for IR panel) |

|

Cover Lifting Mode |

Electric Screws |

|

IR-3350P Series Curing Oven Specification |

|

|

Item |

3350P |

|

Dimension and Weight-IR-3350P |

|

|

Dimension L*W*H |

L3300mm*W1135mm*H1145mm |

|

Weight |

Approx.800kg |

|

Transport System |

|

|

Transport Height |

900±20mm |

|

Transport Speed |

0.1-3.5m/min |

|

Transport Direction |

L-R |

|

Transport Motor |

AC220V 90W |

|

Transport Mode |

Pin Chin (35B 5mm Stainless Steel) |

|

Width Adjustment |

MAX 450mm |

|

Heating System |

|

|

Heating Mode |

IR Panel (optional with IR Tube) |

|

Heating Zones |

5Sets (Top5, Bottom 5 is an option) |

|

Temperature Scope |

Room temp to 150℃ (IR Tube), Room temp to 250℃ (IR Panel ) |

|

Temperature Rising Time |

8mins(To 150℃) (for IR Tube), 15mins(To 250℃) (for IR Panel) |

|

PCB Size |

MAX W450*L450 |

|

PCB Clearance |

Top Side 60MM Bottom Side 60MM |

|

Control System |

|

|

Control Mode |

Touchscreen |

|

Power Supply |

AC380V |

|

Total Power |

17KW |

|

Running Power |

Top only (12-14kw for IR tube, 7-9KW for IR panel) |

|

Cover Lifting Mode |

Electric Screws |

|

IR-3355P Series Curing Oven Specification |

|

|

Item |

3355P |

|

Dimension and Weight-IR-3355P |

|

|

Dimension L*W*H |

L3300mm*W1135mm*H1145mm |

|

Weight |

Approx.900kg |

|

Transport System |

|

|

Transport Height |

900±20mm |

|

Transport Speed |

0.1-3.5m/min |

|

Transport Direction |

L-R |

|

Transport Motor |

AC220V 90W |

|

Transport Mode |

Pin Chin (35B 5mm Stainless Steel) |

|

Width Adjustment |

MAX 450mm |

|

Heating System |

|

|

Heating Mode |

IR Panel (optional with IR Tube) |

|

Heating Zones |

5 Sets (Top 5, Bottom 5) |

|

Temperature Scope |

Room temp to 150℃ (IR Tube), Room temp to 250℃ (IR Panel ) |

|

Temperature Rising Time |

8mins(To 150℃) (for IR Tube), 15mins(To 250℃) (for IR Panel) |

|

PCB Size |

MAX W450*L450 |

|

PCB Clearance |

Top Side 60MM Bottom Side 60MM |

|

Control System |

|

|

Control Mode |

Touchscreen |

|

Power Supply |

AC380V |

|

Total Power |

33KW |

|

Running Power |

Top bottom (25--27kw for IR tube, 15-18KW for IR panel) |

|

Cover Lifting Mode |

Electric Screws |

|

IR-4060P Series Curing Oven Specification |

|

|

Item |

4060P |

|

Dimension and Weight-IR-4060P |

|

|

Dimension L*W*H |

L4000mm*W1135mm*H1145mm |

|

Weight |

Approx.900kg |

|

Transport System |

|

|

Transport Height |

900±20mm |

|

Transport Speed |

0.1-3.5m/min |

|

Transport Direction |

L-R ; |

|

Transport Motor |

AC220V 90W |

|

Transport Mode |

Pin Chin (35B 5mm Stainless Steel) |

|

Width Adjustment |

MAX 450mm |

|

Heating System |

|

|

Heating Mode |

IR Panel (optional with IR Tube) |

|

Heating Zones |

6 Sets (Top 6, Bottom 6 is an option) |

|

Temperature Scope |

Room temp to 150℃ (IR Tube), Room temp to 250℃ (IR Panel ) |

|

Temperature Rising Time |

8 mins(To 150℃)(for IR Tube), 15mins(To 250℃) (for IR Panel) |

|

PCB Size |

MAX W450*L450 |

|

PCB Clearance |

Top Side 60MM Bottom Side 60MM |

|

Control System |

|

|

Control Mode |

Touchscreen |

|

Power Supply |

AC380V |

|

Total Power |

20KW |

|

Running Power |

Top only (14-17kw for IR tube, 8-10KW for IR panel) |

|

Cover Lifting Mode |

Electric Screws |

|

IR-4066P Series Curing Oven Specification |

|

|

Item |

4066P |

|

Dimension and Weight-IR-4066P |

|

|

Dimension L*W*H |

L4000mm*W1135mm*H1145mm |

|

Weight |

Approx.900kg |

|

Transport System |

|

|

Transport Height |

900±20mm |

|

Transport Speed |

0.1-3.5m/min |

|

Transport Direction |

L-R |

|

Transport Motor |

AC220V 90W |

|

Transport Mode |

Pin Chin (35B 5mm Stainless Steel) |

|

Width Adjustment |

MAX 450mm |

|

Heating System |

|

|

Heating Mode |

IR Panel (optional with IR Tube) |

|

Heating Zones |

6 Sets (Top6 , Bottom 6) |

|

Temperature Scope |

Room temp to 150℃ (IR Tube), Room temp to 250℃ (IR Panel ) |

|

Temperature Rising Time |

8mins(To 150℃) (for IR Tube), 15mins(To 250℃) (for IR Panel) |

|

PCB Size |

MAX W450*L450 |

|

PCB Clearance |

Top Side 60MM Bottom Side 60MM |

|

Control System |

|

|

Control Mode |

Touchscreen |

|

Power Supply |

AC380V |

|

Total Power |

38KW |

|

Running Power |

Top & bottom (29-32kw for IR tube, 19-22KW for IR panel) |

|

Cover Lifting Mode |

Electric Screws |

|

IR-2030P Series Curing Oven (P means IR panel, without P means IR tube) Dimension |

|

|

IR-2030P(Upper 3) |

L2000mm*W1135mm*H1145mm |

|

IR-2033P (Upper 3/Bottom 3) |

L2000mm*W1135mm*H1145mm |

|

IR-2660P(Upper 4) |

L2600mm*W1135mm*H1145mm |

|

IR-2644P(Upper 4/Bottom 4) |

L2600mm*W1135mm*H1145mm |

|

IR-3350P(Upper 5) |

L3300mm*W1135mm*H1145mm |

|

IR-3355P(Upper 5/Bottom 5) |

L3300mm*W1135mm*H1145mm |

|

IR-4060P(Upper 6) |

L4000mm*W1135mm*H1145mm |

|

IR-4066P(Upper 6/Bottom 6) |

L4000mm*W1135mm*H1145mm |

|

IR-2030P Series Curing Oven (P means IR panel, without P means IR tube) Power |

|

|

IR-2030P(Upper 3) |

IR Tube/9.5KW |

| IR Panel/10KW | |

|

IR-2033P (Upper 3/Bottom 3) |

IR Tube/18.5KW |

| IR Panel/19KW | |

|

IR-2660P(Upper 4) |

IR Tube/13KW |

| IR Panel/13.5KW | |

|

IR-2644P(Upper 4/Bottom 4) |

IR Tube/25KW |

| IR Panel/26KW | |

|

IR-3350P(Upper 5) |

IR Tube/16KW |

| IR Panel/17KW | |

|

IR-3355P(Upper 5/Bottom 5) |

IR Tube/31KW |

| IR Panel/33KW | |

|

IR-4060P(Upper 6) |

IR Tube/19KW |

| IR Panel/20KW | |

|

IR-4066P(Upper 6/Bottom 6) |

IR Tube/37KW |

| IR Panel/38KW | |

|

IR-2030P Series Curing Oven Tunnel Length |

|

|

IR-2030P/IR-2033P(Upper 3/Bottom 3) |

1750mm |

|

IR-2660P/IR-2644P(Upper 4/Bottom 4) |

2350mm |

|

IR-3350P/IR-3355P(Upper 5/Bottom 5) |

3000mm |

|

IR-4060P/R-4066P(Upper 6/Bottom 6) |

3600mm |

|

|

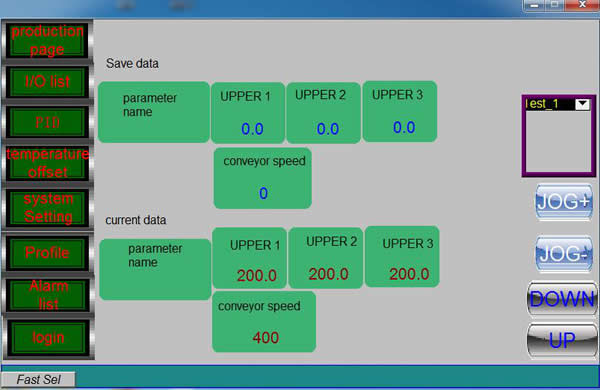

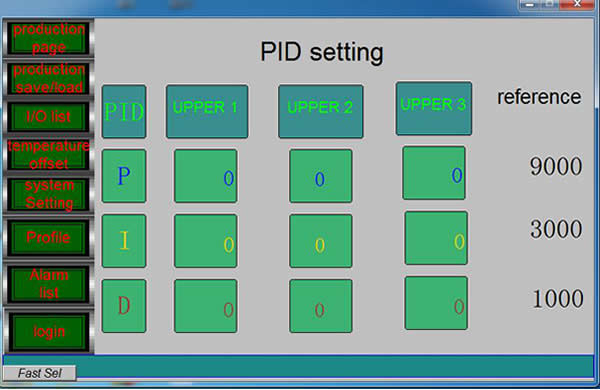

● Touchscreen & PLC for controlling system. Can save all the temperature, speed parameters. |

|

|

● PID for temperature controlling. |

|

● Program Saving System. |

|

|

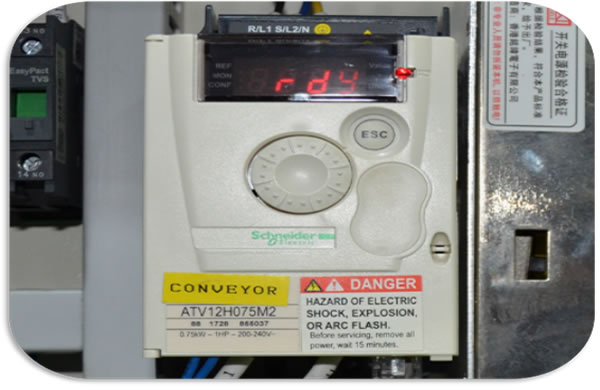

● Brand electrical component like Schneider (German) breaker, Omron (Japan) box breaker. It runs stable and lower noise. |

|

|

● At entrance and exit there are plate we can adjust the height, so to prevent heat lose from both end. |

|

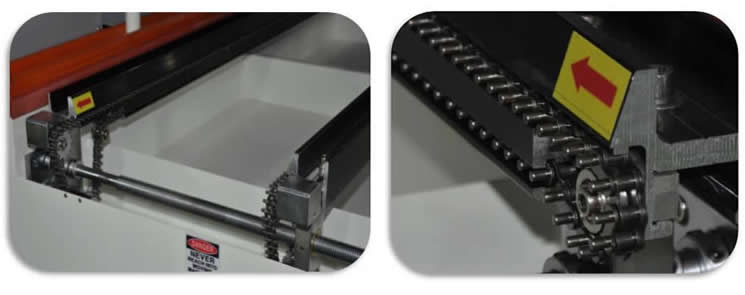

● Stainless steel chain conveyor with harden guiding rails, 5MM pin length for conveyor chain. |

|

|

|

|

● Conveyor width adjustment system |

|

|

|

|

● The cure chamber achieves a thermally uniform atmosphere with Japan designed Far IR Panel. |

|

|

|

Our customers:

0 review for Donec eu furniture

Related Products

UV Curing Machine UVC-502 Series

- Model: UVC-502

Add a review

Your email address will not be published. Required fields are marked