- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

Flex-i2 Inline Selective Soldering Machine

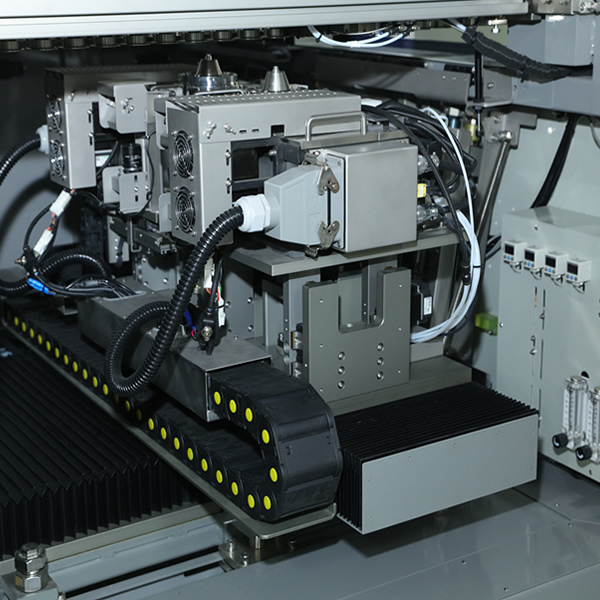

Machine working concept: PCB will be moved in machine with stainless steel wheels conveyor system, after it's stopped by stopper, it will be side clamped by rear clamper cylinder, then the spray fluxer will start to work under setting program, after that the same table will move x,y,z1,z2 to move different solder pot under PCB for selective soldering. During whole process, the top preheater can be on to help keep the PCB's temperature.

Flex-i2 Inline Selective Soldering Machine

×|

|

Spray Flux ● Flx-DropJet : Standard equipped with drop jet valve from Germanny originally, which can meet dia 2mm flux dot dimension. |

|

|

Selecting Soldering Pot ● Titanium soldering pot, 100% capable for lead free application. Standard equipped with mechanical pump, easy for maintenance. ● N2 direct heating system is standard equipped,enhance the wetting ability for lead free sodlering. |

|

|

Live camer ● Sod-ProcMoni: Without open machine's door, operator can see soldering process in real time. |

|

|

Preheating ●Pre-TPRE: Standard equipped with upper preheating zone, to reduce the temperature drop on PCB during soldering, especially for thick PCB or heat absorber component, and preheart time & heating ratio(%) can be set in software.option with bottom preheat. |

|

|

Solder nozzle ● Sod-WetNoz: Standard equipped with wet nozzle for customer's universal applicaiton. Can also design solder nozzle according cusotmer's application. |

|

Inline Selective Soldering Machine Flex-i2 Features: |

|

● XY servo table for solder station, servo axis Z1 for solder pot 1, servo axis Z2 for solder pot 2. Optional with electro-magnetic pump made in Germany. |

|

● Top preheating zone, option with bottom IR zone. |

|

● Standard equipped live-on camera for both solder pot's soldering process. |

|

● Standard equipped with wave height calibration. |

|

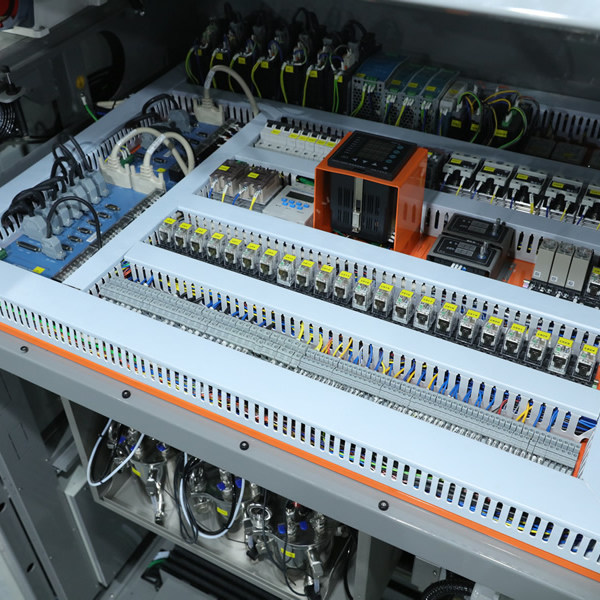

● Windows 10 system English version. |

|

● Drop jet fluxer made in German. Option to install double drop jet fluxer. |

|

FLEX-i2 Specifications |

|

|

Item |

FLEX-i2 |

|

General |

|

|

Operating power/Max power |

6KW/16KW |

|

PCB dimension |

Min50x50---Max PCB W457.2xL508mm (18" x 20") (Two nozzle solder individually) Max PCB W508 x L508mm (20" x 20") (Two nozzle solder parallel) |

|

Machine dimension |

1420(L)*1725(W)*1700(H) |

|

Net weight |

900KG |

|

Power supply |

3PH 380V 50HZ |

|

Air supply |

3-5 bars |

|

Exhausting required |

800M3/h |

|

PC |

Yes |

|

Typical Program Time |

10 Minutes |

|

PCB Robotic Platform |

|

|

Flux Nozzle Type |

drop jet fluxer made in Germany |

|

Flux Nozzle Quantity |

Standard equip 1 set, optional to equip another set |

|

Flux Tank Capacity |

1L |

|

Flux Tank Quantity |

Standard equip 1 set, optional to equip another set (when use two different flux) |

|

preheat |

|

|

Preheating method |

Top IR preheat, option with bottom preheat |

|

Solder Management |

|

|

Solder pot type |

Standard equipped with mechanical pump, optional with electromagnetic pump (made in Germany) |

|

Standard Solder Stations |

2 |

|

Solder Pot Capacity |

15kgs |

|

Solder Temperature Control |

PID |

|

Heat-Up Time |

About 40mins |

|

Max Temperature |

350℃ |

|

Mini Wave Nozzles |

3 to 12mm |

|

Customized nozzle |

Available |

|

Axes of Motion |

X, Y, Z1, Z2 |

|

Position Accuracy |

+ / - 0.05mm |

|

(N2) Inertion Management |

|

|

N2 Consumption per Nozzle |

4m3/H |

|

Required N2 Purity |

>99.99% |

|

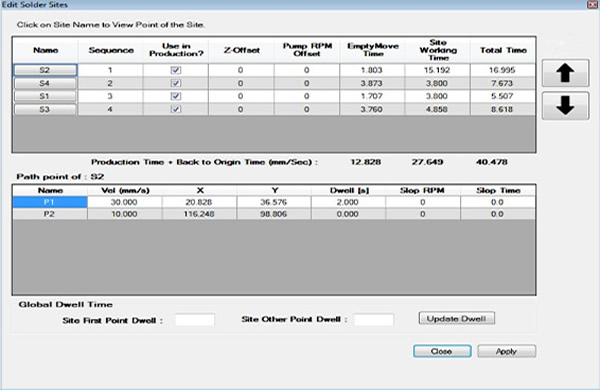

Software System “Solder it” is windows10 based software. With board scanned picture or Gerber file, “POINT AND CLICK” to “draw and drag” motion path easily, make the initial programming in less than 10 minutes. Path programming : |

|

|

|

“Point and Click” ● to draw path with scanned picture as background, easiest way for path programming. |

|

|

Solder path editing: ● Moving speed,Z height, wave height, Dwell time, wave slope speed etc are editable, get max flexibility to fit different type of components on the board. Empth move time, site working time, total cycle time are estimated once path programming finished. Easy for balance production line. |

|

|

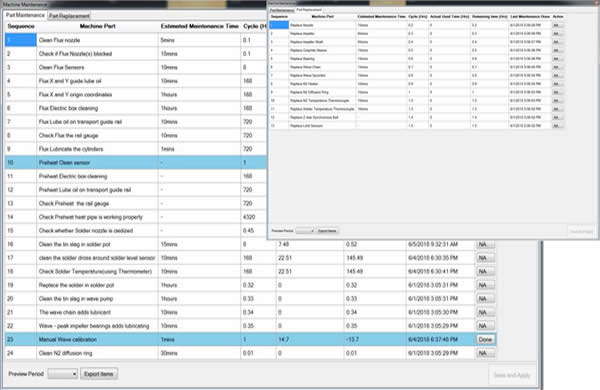

Maintenance & replacement assisting function : ● we know how important the maintenance for a selective soldering machine. In the software, we list all maintenance job, time taking, comsumable parts life and remain life, etc. It can export to excel list, engineer can check what parts need to replace in next 3 month or 6 months, in this way to they can prepare everything in advance. |

0 review for Donec eu furniture

Related Products

Ant-i2 Offline Selective Soldering Machine

- Model: Ant-i2

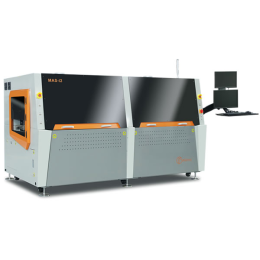

MAS-i2 Inline Selective Soldering Machine

- Model: MAS-i2

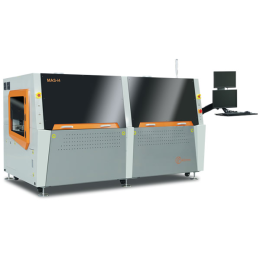

MAS-i4 Dual pot selective machine

- Model: MAS-i4

Unit-i1 inline 1 nozzle compact selective soldering

- Model: Unit-i1

Unit-i4 inline 4 nozzle compact selective soldering

- Model: Unit-i4

Add a review

Your email address will not be published. Required fields are marked