- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

|

|

Image and optical system ● Using uniform ring light and high brightness coaxial light with promise brightness adjustment function, then all types of Mark points can be well recognized (Including the rugged Mark points), applicable for tin plating, coppering, gold plating, tin spraying, FPC and other types PCB with of different colors. With GKG patent mathematical model, able to ensure high accuracy. |

|

|

Cleaning system ● GKG cleaning system equipped with three cleaning methods: dry cleaning, wet cleaning, vacuum, which can be combined to use. It can also be cleaned by manual if customer do not need to use automatic cleaning to reduce the cleaning time and improve production efficiency. The newly wiping system ensures full contact with the stencil, increased vacuum suction can effectively eliminate the remaining paste in the mesh, which can achieve effective automatic cleaning function. CCD part and cleaning system is separated, when CCD working, CCD part independently move to reduce the servo motor load and improve the machine speed and accuracy. |

|

|

Adjustable Stepping Motor ● Adjustable Stepping Motor - Programmable & Floating Print-Heads. |

|

|

GKG special adjustment jacking platform ● Stable and easy to adjust, it can quickly adjust the pin jacking height of PCB with different thickness. |

|

|

Chinese/English Operating Interface ● The machine adopts windows XP/win7 operating interface with GKG user friendly software. Chinese/English selectable, Menu/Operating Journal/Breakdown Record/Breakdown Diagnosis/Error Analysis/Light Alarm etc |

|

|

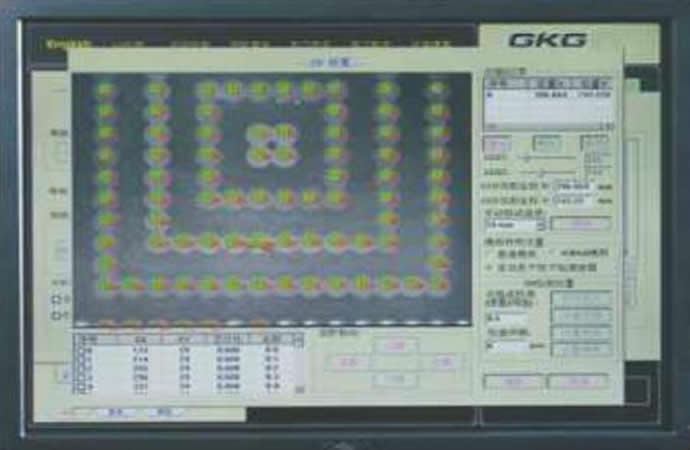

2D Solder Paste Print Quality Inspection and Analysis System ● The 2D system immediately detects solder paste deposition defects such as deviation Jack paste, miss paste,paste joint etc, and guarantees print quality. |

|

Full Automatic Solder Paste Printing Machine K870 Specification: |

|

|

Model |

K870 |

|

Machine Performance |

|

|

Repeat Position Accuracy: |

±0.01 mm |

|

PrintAccuracy: |

± 0.025mm |

|

NCP-CT: |

< 10.5 sec |

|

HCP-CT: |

25s/pcs |

|

Process CT: |

6 min |

|

Change over CT: |

4 min |

|

Substrate processing parameter |

|

|

Maximum board size: |

870*610mm |

|

Minimum board size: |

100*65mm |

|

Board thickness: |

0.4~8mm |

|

Camera Mechanical range: |

870*610mm |

|

Maximum board weight: |

10kg |

|

Board edge clearance: |

3.5mm |

|

Board height: |

23mm |

|

Transport speed: |

900 ± 40mm |

|

(Max) Transport speed: |

Segmented control, 1500mm/s (Max) |

|

Transport direction: |

One stage |

|

Transmission direction: |

Left to right |

| Right to Left | |

| In and out the same | |

|

Support System: |

Magnetic Pin |

| (65mm)Support Block | |

| (65mm)Patented over the top clamping | |

|

Board clamp: |

Automatic top clamping |

| Side clamping | |

| Adsorption function | |

|

Printing Parameters |

|

|

Print Speed: |

10~150mm/sec |

|

Print Pressure: |

0.5~30Kg |

|

Print Mode: |

One/Twice |

|

Queegee Type: |

Rubber/Squeegee Blade (angle 45/55/60) |

|

Snap-off: |

0-20mm |

|

Snap-Speed: |

0-20mm/sec |

|

The template frame size: |

650*550mm -- 1100*950mm |

|

Steel mesh positioning mode: |

Automatic Y orientation |

|

Cleaning Parameters |

|

|

Cleaning System: |

Dry, Wet Vacuum three modes |

|

High speed cleaning: |

weave cleaning |

|

Cleaning system: |

Top drip |

|

Cleaning stroke: |

Automatic generation |

|

Cleaning position: |

Post cleaning |

|

Cleaning Speed: |

10-200mm/sec |

|

Cleaning fluid consumption: |

Auto & Manually adjustable |

|

Cleaning paper consumption: |

Auto & Manually adjustable |

|

Vision Parameters |

|

|

CCD FOV: |

10*8mm |

|

Camera type: |

130 Thousand CCD Digital camera |

|

Camera System: |

Lock up/down optics structure |

|

Camera Cycle time: |

200ms |

|

Fiducial mark types: |

Standard Fiducial Mark Shape |

| round、square、diamonds cross | |

| Pad and profile | |

|

Mark size: |

0.1-6mm |

|

Mark number: |

Max: 4pcs |

|

Stay away number: |

Max: Ipcs |

|

Machine parameter |

|

|

Power Source: |

AC:220 ±10%, 50/60HZ 2.2KW |

|

Air Pressure: |

4-6Kgf/cm2 |

|

Air Consumption: |

5L/min |

|

Operating Temperature: |

-20℃~+45℃ |

|

Working environment humidity: |

30%~60% |

|

Machine dimension (without Tower light): |

1530(H) mm |

|

Machine Length: |

1590(L) mm |

|

Machine Width: |

1608(W) mm |

|

Machine Weight Approx: |

Approx: 1500Kg |

|

Equipment load bearing requirements: |

650Kg/㎡ |

0 review for Donec eu furniture

Related Products

Full Automatic Solder Paste Printing Machine G9+

- Model: G9+

Full Automatic Solder Paste Printing Machine GSE

- Model: GSE

Full Automatic Solder Paste Printing Machine GSK

- Model: GSK

Full Automatic Solder Paste Printing Machine GTS

- Model: GTS

Full Automatic Solder Paste Printing Machine GT++

- Model: GT++

Add a review

Your email address will not be published. Required fields are marked