- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

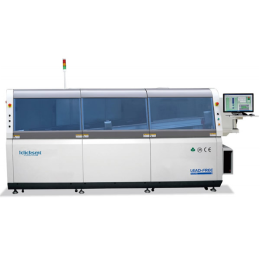

Medium Volume Lead Free Wave Solder Machine M Series

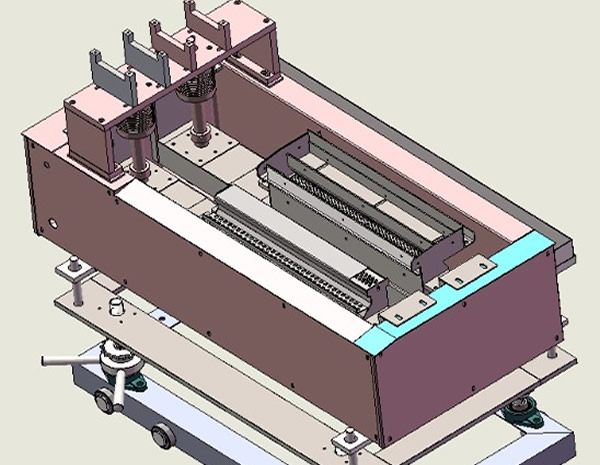

M seires is a CE certificated, compact Lead Free Wave Solder Machine with inline finger conveyor, stepper driven spraying fluxer, hot air preheat zone & Ti dual wave solder pot, it is suited for medium volume production.

Available Options

Medium Volume Lead Free Wave Solder Machine M Series

×|

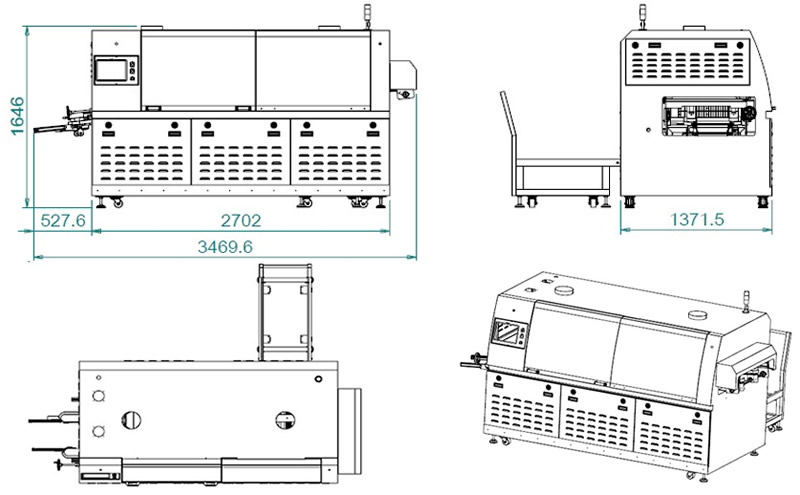

M series Lead Free Wave Solder Machine Structure: |

|

M400 |

|

|

M400 plus |

|

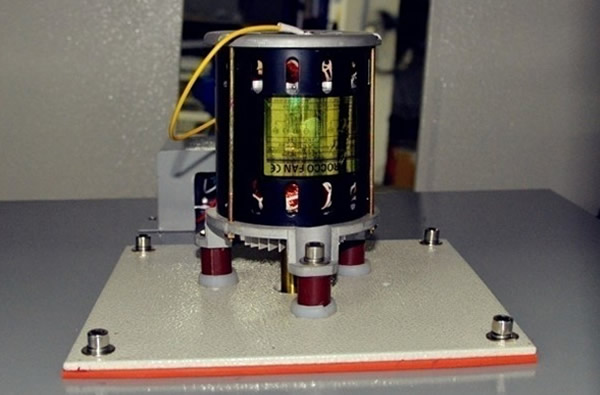

| Conveyor System In-loading system: which can connect with the insertion conveyor directly, the sensor at bottom for counting and spray fluxer on/off; with ruler and and needle for instruction of width |

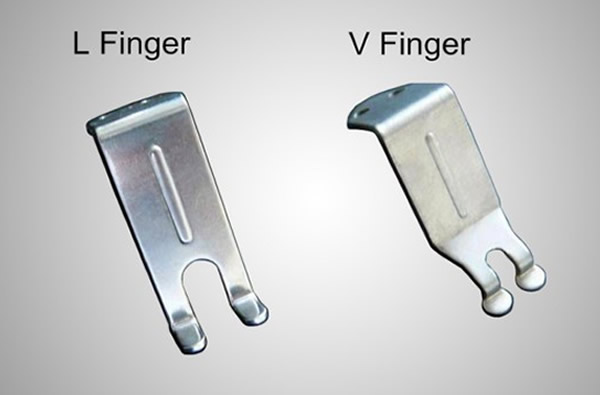

| Conveyor System Standard: V type Ti finger for standard conveyor. |

| Conveyor System Option: V type Ti finger or V mixed with L finger. |

| Conveyor System Optional with heavy load finger which made of 5mm Ti, it can transport PCB weight as 20kgs/unit. |

| Option: Central Support System ● Width Adjustable ● Height Adjustable |

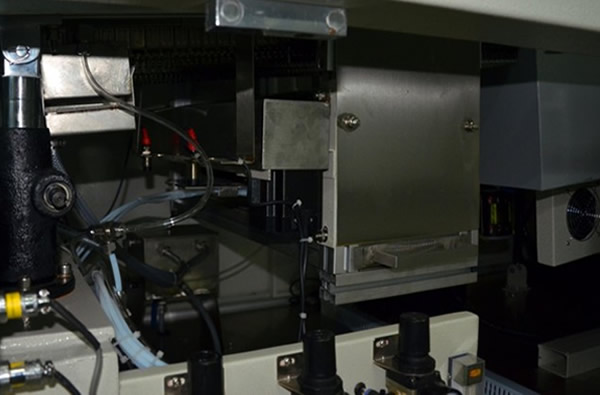

| Flux System Stepper motor/driver etc, make sure the spray nozzle moving at needed speed smoothly. |

| Flux System sprayer's flow, flux shape, automization etc adjustable, so to meet a perfect flux applying performance. |

| Flux System Flux is adding via a SMC pump automaticlly, save operator's time and job. (Option) |

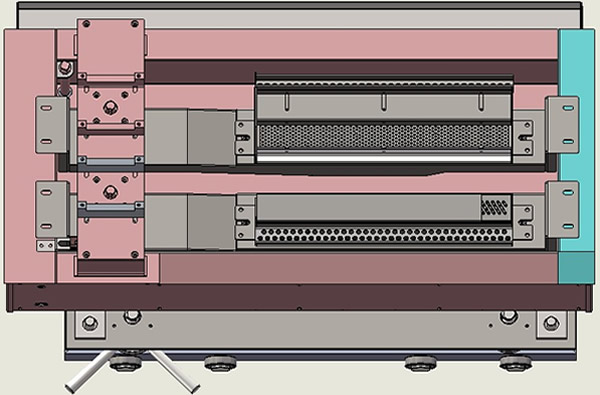

| Preheating System M400 is Standard equipped with 2 hot air convection preheating zone at bottom, top preheating is optional. M400 plus is Standard equipped with 3 hot air convection preheating zone at bottom, top preheating is optional. |

| Preheating System Heater can be take out from rear side of machine, easy for maintenance. |

| Preheating System Blower motor can be take out from upper side of machine, easy for maintenance. |

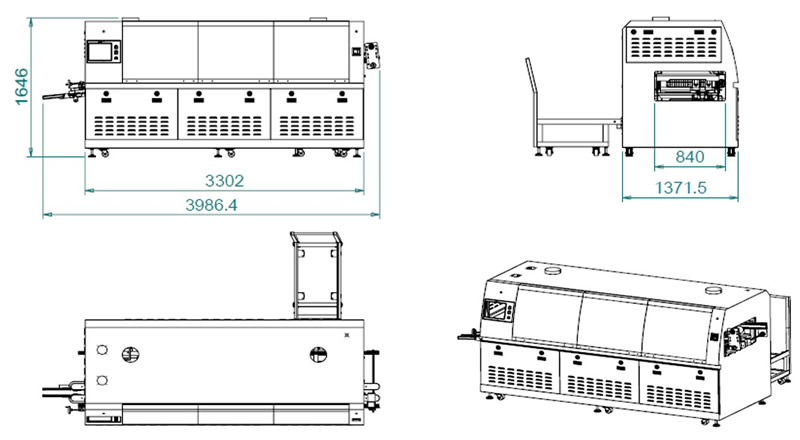

| Soldering System Fully Ti material made solder pot, even for impeller, shaft, nozzle, and bolts. All is Ti and 100% capable for Lead free. Two wave nozzle, one is for turbulent wave and another is for flat wave. |

| Soldering System Solder pot in/out automaticlly, up/down manually |

| Soldering System Option:Solder pot included solder level detection system |

| Soldering System New design of tunnel and wave nozzle |

| Soldering System ● Dual Wave Nozzle ● Fully Titanium Solder Pot and Wave Nozzle ● Adjustable Wave Height by Touchscreen ● Adjustable Wave Width ● Reduce Oxidation Design |

| Soldering System Solder pot is connected with a quick connector, easy to change solder pot if customer had one for leaded pot and another for lead free pot. |

| Soldering System Optional with N2 feeding system. |

| Electrical System All brand electrical parts, such as Panasonic conveyor motor, Mitsubishi breaker, etc all wiring cetificated by CE. |

| Electrical System Touchscreen and PLC for controlling system |

M series Lead Free Wave Solder Machine Features: |

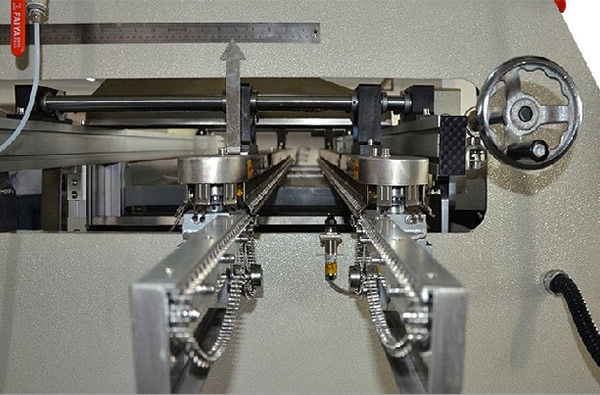

● A new streamline design replaces a conventional right-angled exterior. And the design is based on mechanical aesthetics and practicability, making the maintenance an easy job. |

● PLC controller, Touchscreen form a stable, safe and efficient controlling system, easy for operation. |

● The software has the functions like PCB counting, temperature setting and editing, PCB parameter menu, and profile testing, alarms and muti-languages conversion. In the meanwhile, the software has make a lots effect about the safety issues just like wave motor running safe temperature etc. |

● The one-week timer will provide a amazing function for customer. The operator can edit his work schedule for this wave solder machine weekly. And the machine can turn on automatically to melt the solder before operator come to work. When it’s time to work, the solder has been melt and everything is ready. It will save about 1.5 hours for customer everyday. |

● The specially designed guiding rail reduce the deformation caused by heat; After two years working you only need to change the cooper bars instead of change the whole conveyor rails. |

● Sprayer driven by stepper motor , the speed can be set on touchscreen. The moving and stopping time will be set in a more precious way. |

● High quanlity sprayer provides perfect atomization performance of the flux. |

● Adding flux automatically(Option), there are two sensors on flux tank. When flux is lower than limit,it will switch on the pump to feed flux in automatically. Operator just need to put the whole barrel flux into the flux tank, meanwhile put the sucking tube into the barrel. |

● Forced air convection preheat zone control by temperature controller in PID model. The preheat zone will provide enough uniform heat for the PCB. |

● M400 with 2 individual bottom hot air zone, M400 plus with 3 individual bottom hot air zone, this configuration will provide the greatest preheating effect for soldering. |

● Adopt cast iron heater for the solder pot, it’s mounted outside of the solder pot. This new assembling way will prolong the life of the solder pot. |

● Dual wave nozzles. Both wave heights are controlled by transducer. Changing the wave height via adjusting the frequency of power. |

● Solder pot is made of 3mm thickness Ti material. Long life warranty. |

| ● High quality wave motor with small noise and more stable. |

M series Lead Free Wave Solder Machine Specification: | ||

Model | M400 | M400 plus |

PCB width | 30-400MM | 30-400MM |

Solder Pot Volume | 390kg | 390kg |

Running power /General power | 8-12KW/22KW | 10-14KW/26KW |

Machine Dimension | 3470(L)*1372(W)*1650(H) | 3987(L)*1372(W)*1650(H) |

Net Weight | 1000KG | 1200KG |

Controlling System | Panel control | Panel control |

Conveyor Motor | 3Ph 220V, 90W | 3Ph 220V, 90W |

Conveyor Speed | 200MM-1500MM/Min | 200MM-1500MM/Min |

Flux Volume | 5 Liters | 5 Liters |

Alcohol Volume | 3.5 Liters | 3.5 Liters |

PCB Direction | Left to Right | Left to Right |

Spray drive | Stepper motor drive | Stepper motor drive |

Sparyer | Stainless Steel Nozzle | Stainless Steel Nozzle |

Preheat | 2 hot air convection zone | 3 hot air convection zone |

Preheat power | 5kw/zone | 5kw/zone |

Length of preheating zone tunnel | 1095mm | 1645mm |

Solder Pot Material | Ti | Ti |

Preheater power | 2KW*2pcs /each zone * 2 zone | 2KW*2pcs /each zone * 3 zone |

Solder Pot heater Power | 1.2KW*10PCS | 1.2KW*10PCS |

Wave Number | Dual Waves | Dual Waves |

Time for Solder Melt | 60 Minutes | 60 Minutes |

Solder Pot Up/Down | Manual | Manual |

Solder Pot In/Out | Automaticlly | Automaticlly |

Conveyor Type | Ti finger | Ti finger |

Solder Angle | 3-6° | 3-6° |

Air Supply | 3-5BAR | 3-5BAR |

Power supply | 3PH 380V 50HZ, Optional: 3PH 220V 60HZ | 3PH 380V 50HZ, Optional: 3PH 220V 60HZ |

M series Lead Free Wave Solder Machine included: |

● Lead free wave solder machine M400/400 plus |

● Spraying system driven by step motor and PLC controller |

● 2 individual preheating zones with M400; 3 individual preheating zones with M400 plus |

● Titanium alloy dual wave solder pot |

● Titanium alloy finger conveying system |

● Touchscreen and PLC control system |

● 1 year parts warranty |

0 review for Donec eu furniture

Related Products

Power Wave Series Lead Free Wave Soldering Machine

- Model: Power wave 180/35

Lead Free Wave Solder Machine E400

- Model: E400

Add a review

Your email address will not be published. Required fields are marked