- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

Offline PCBA Cleaner AQ-650

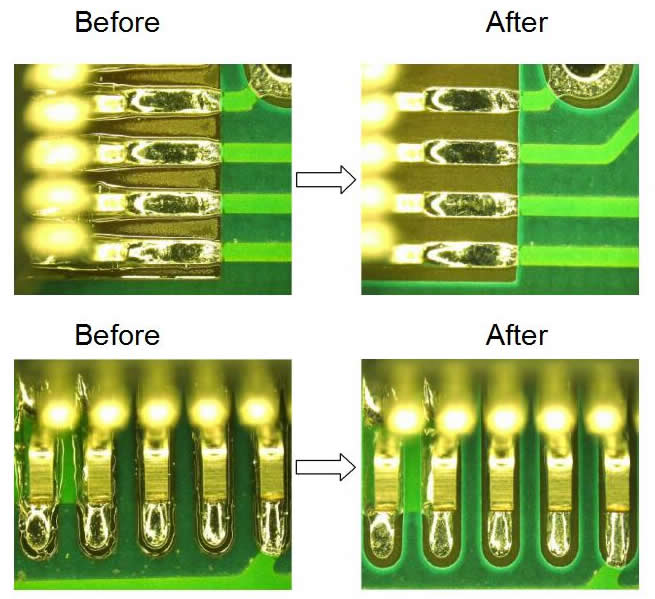

AQ-650 is mainly developed for the cleaning of PCBA in the electronics manufacturing industry. It uses the industry's most advanced cleaning process “water-based liquid” for cleaning, achieving 99% cleaning and environmental protection. The machine consists of a cleaning system, a rinsing system, a drying system, a filtration system.

Offline PCBA Cleaner AQ-650

×|

|

● Visualization of the whole process: Cleaning room equipped with visual windowcleaning process can be monitored at all time. ● Large cleaning baskets:610mm(L) ×560mm(W) × 100mm(H) 2 layer , Meet larger PCBA sizes and higher cleaning production. |

|

|

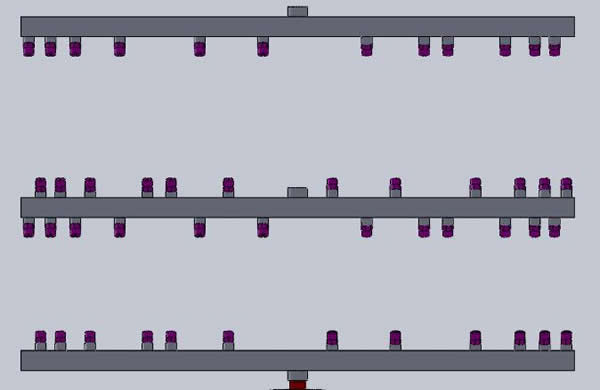

● Spraying System: Upper and bottom spraying system, each 12 sets nozzles , total 48 sets nozzle to make sure 360 degree cleaning. ● The most scientific nozzle design(patent ):Increasing nozzles from left to right, Enhance the cleaning efficiency, Distribution nozzles up and down, Completely solve the blind clean area |

|

|

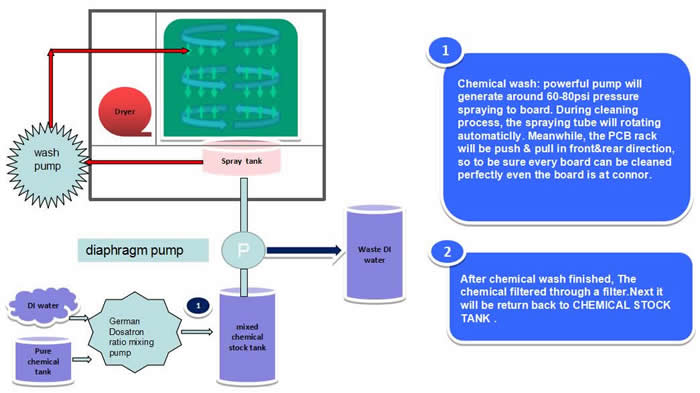

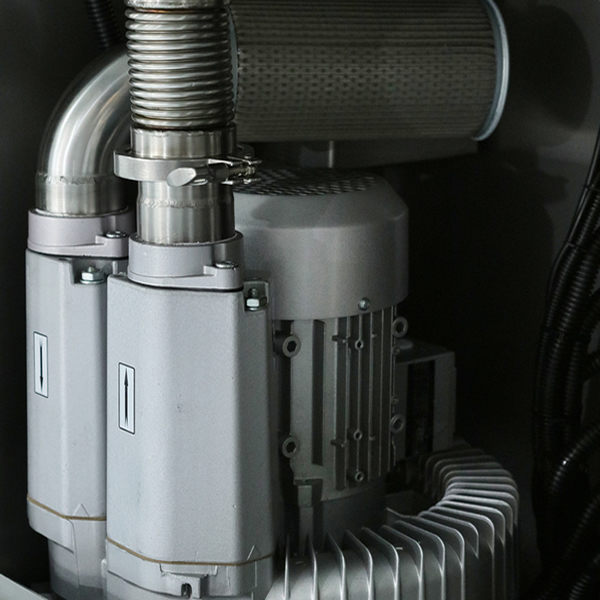

● Spray Pump System: High power(5.5KW) & high efficiency stainless steel spray pumps, spray pressure can reach 60 ~ 80PSI, pressure can be adjusted based on actual requirement to clean the contamination. |

|

|

● Nozzle pressure is adjustable |

|

|

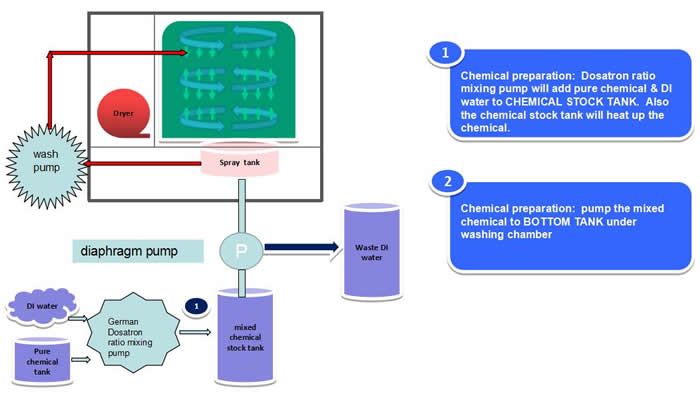

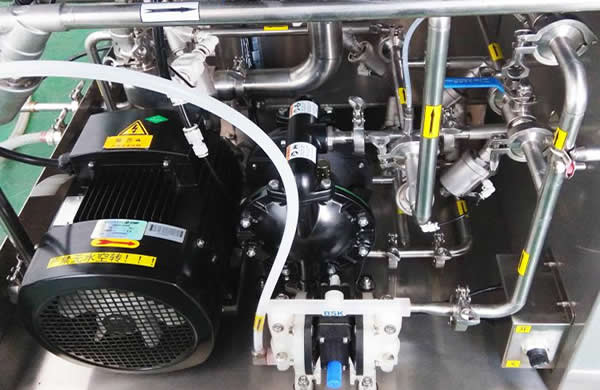

● Convenient liquid add System: Adopt “Dosatron Automatic mixing System” from Germany, it can set according to proportion (5% ~ 25%) automatic proportioning DI water and chemical liquid. |

|

|

● Circulating and Filtering System: Adopt 0.45μm filter, can filter dust and other particulate impurities. So that the chemical liquid recycling can be maintained better cleaning performance and longer life. Meanwhile ,can reduce operating costs. |

|

|

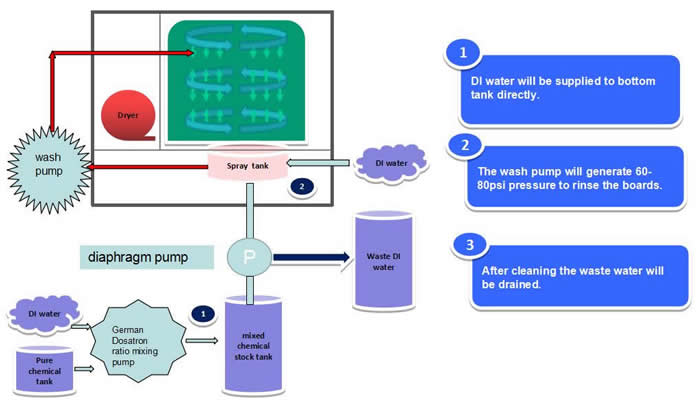

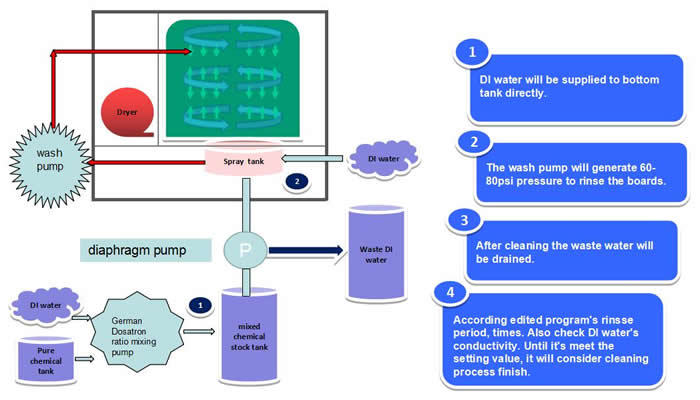

● DI water conductivity mointor. |

|

|

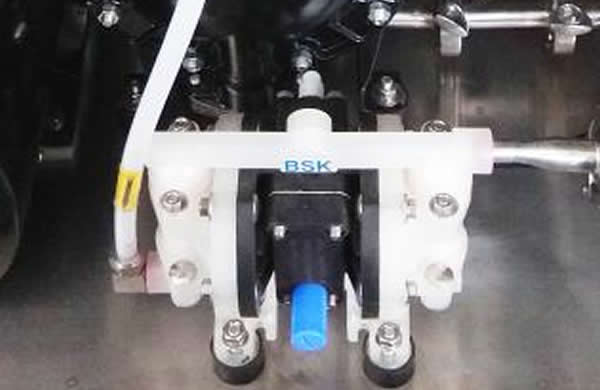

● Independent chemical liquid adding pump. |

|

|

● Drying system. |

|

Offline PCBA Cleaner AQ-650 Features: |

| ● Visualization of the whole process: Cleaning room equipped with visual window cleaning process be clear at a glance. |

|

● Large cleaning baskets:610mm(L) ×560mm(W) × 100mm(H) 2 layer , Meet larger PCBA sizes and higher cleaning production. |

|

● The most scientific nozzle design:Increasing nozzles from left to right, Enhance the cleaning efficiency, Distribution nozzles up and down, Completely solve the blind clean area. |

|

● Nozzle pressure adjustable design: Solve the small size of PCBA in the cleaning process by spray under high pressure collision, splash problem. |

|

● With standard diluents slot heating system: Greatly promoted cleaning efficiency. Shorten cleaning time. |

|

● Touch screen interface: According to different PCBA model set with different process parameters, Quick edit and variety of different process parameters can be stored program, including, solvent temperature, cleaning time, rinse times/ time, rinse temperature, dry time, drying temperature, conductivity monitoring parameters, etc... According to different permissions, operator, management authority. |

|

● High standards of cleanliness: Ion pollution completely accords with the 610D IPC - Ⅰ class standard (less than 1.5 ug/cm2, and the U.S. army standard of MIL28809 Ⅰ class standard. |

|

● Convenient liquid adding mode: Can manually add chemical liquid , also can set according to proportion (5% ~ 25%) automatic proportioning DI water and chemical fluid. |

|

● Comprehensive cleaning system: according to the product surface residual organic matter, inorganic matter thoroughly effective cleaning. |

|

● Automatic cleaning mode: in a clean indoor finish all cleaning, rinsing and drying process, small size, compact structure. |

|

Offline PCBA Cleaner AQ-650 specification : |

|

|

Model |

AQ-650 |

|

Clean Basket Size |

Max 610mm(L) X560mm(W) X100mm(H)mm 2layers |

|

Max Product Size |

Max 600mm(L) X520mm(W) X150mm(H)mm |

|

Min Product Size |

Min 20mm(L) X20mm(W) X150mm(H)mm , the small product need customized fixture to fix it. |

|

Dilution Tank Capacity |

Max 70L |

|

Chemical Liquid Tank Capacity |

30L |

|

Spray Tank Capacity |

17L-23L |

|

Cleaning method |

360°Whirl/Ejection for cleaning; hot air for drying |

|

Cleaning Time |

5~20 Minutes ( Reference ) |

|

Rinsing Time |

1-2 Minutes ( Reference ) |

|

Rinsing Times |

1-10(Set) |

|

Drying Time |

20~30 Minutes ( Reference ) |

|

Cleaning Liquid Recovery Filter |

0.45um ( filter tiny impurities: solder paste, flux, rosin and pollutants ) |

|

Rinsing Liquid Discharge Filter |

0.45um ( filter tiny impurities: solder paste, flux, rosin and pollutants ) |

|

Dilution Liquid Heating Temperature |

Room temperature~75° |

|

Drying Heating Temperature |

Room temperature~75° |

|

Resistivity Meter Monitoring Range |

0mΩ~18mΩ.cm |

|

DI Water Supply |

30~60L/min |

|

DI Water Pressure |

0.2-0.4Mpa |

|

DI Water Entrance Pipe Connection |

6/8 inch |

|

Dilution Tank Heating Power |

9KW |

|

Drying Heating Power |

6KW |

|

Cleaning Motor |

5.5KW |

|

Total Power |

21KW |

|

Total Current |

55A |

|

Air consumption |

200-400L/Min |

|

Air Supply |

0.45Mpa~ 0.7Mpa |

|

Chemical liquid Adding |

Automatic |

|

Power Supply |

3Phase 380V 50/60HZ |

|

Net Weight |

Approx 480Kg |

|

Exhaust Size |

Φ100mm(W)×30mm(H) |

|

Machine Size |

L1200 × W1100 × H1830(mm) |

| Offline PCBA Cleaner AQ-650 Cleaning process : |

|

AQ-650 Process Diagram (preparation): |

|

|

AQ-650 Process Diagram (chemical cleaning): |

|

|

AQ-650 Process Diagram (DI water rinsing): |

|

|

AQ-650 Process Diagram (Repeat DI rinse): |

|

| Offline PCBA Cleaner AQ-650 Application : |

|

|

Offline PCBA Cleaner AQ-650 configuration : |

|

Offline PCBA Cleaner AQ-650 includes : |

|

● Offline PCBA Cleaner AQ-650*1 set |

|

● 0.45μm filter core *2pcs |

|

Optional consumable parts: |

|

● 0.45μm filter core (consumable parts , service life : 15 days ) |

|

● sealing strip (consumable parts, service life : around 3 months) |

|

● Liquid level tube (consumable parts ,service life : around 1 year) |

|

● Liquid level sensor (consumable parts ,service life : above 1 year) |

0 review for Donec eu furniture

Related Products

Pallet Cleaner AQ-601

- Model: AQ-601

ZQ-6800I Inline PCBA Cleaning Machine

- Model: ZQ-6800I

Pneumatic Scraper And Misprinted PCBA Cleaner PSC-600

- Model: PSC-600

Vertical Cleaner for Stencil & PCBA VSP-870

- Model: VSP-870

Add a review

Your email address will not be published. Required fields are marked