- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

Pallet Cleaner AQ-601

AQ-601 is mainly developed for the cleaning of Pallet, condensator, filter, Titanium claw and other surface of electronic, hardware etc, use recylable cleaning liquid, it not only can greatly improve the cleaning efficiency, but also be beneficial to environmental protection.

Available Options

Pallet Cleaner AQ-601

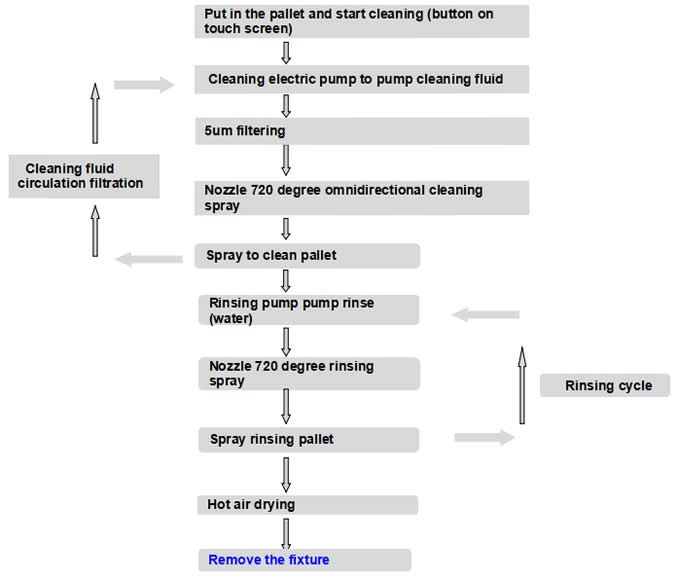

×| Pallet Cleaner AQ-601 Cleaning process : |

|

Pallet cleaning process: |

|

|

|

1. Place pallet to be cleaned, rotate automatically when clean, rinse and dry pallet, 1m diameter cleaning basket, can place a number of tools at one time, to achieve batch cleaning. 2. The whole process of cleaning and drying is about 30 to 40 minutes. |

|

|

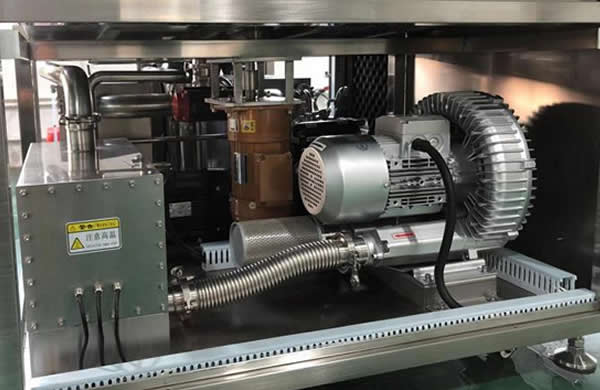

A. High-quality, large-flow electric cleaning pump, high output pressure, high flow rate and good cleaning effect. B. The durable heating element and the large flow blower ensure the drying effect and improve the drying speed. |

|

|

a. All SUS304 stainless steel liquid pipes, no corrosion, no liquid leakage. b. Cleaning liquid, rinsing water adding and discharging are completely automatic. c. The cleaning tank and the rinsing tank store the cleaning liquid and the rinsing liquid independently. |

|

|

well-known brand electrical parts such as Mitsubishi PLC, touch screen, frequency converter, Schneider relay, LS contactor, CKD solenoid valve, etc, ensure long service life. |

|

Pallet Cleaner AQ-601 Features: |

| 1, Batch cleaning, rapid cleaning and high efficiencyl. |

|

2, Up-and-down, left and right all-round cleaning, thorough cleaning and high cleanliness. |

|

3, Use water-based cleaning liquid which is beneficial for environmental protection. |

|

4, Cleaning liquid is Recyclable to save it. |

|

5, Equipped with air knife, Pallet can be completely dried. |

|

6, Spray cleaning solution, not damage pallet . |

|

7, PLC with touchscreen, easy operation . |

|

8, Machine adopt well-known brand electrical parts such as Mitsubishi PLC, touch screen, frequency converter, Schneider relay, LS contactor, CKD solenoid valve, etc, ensure long service life. |

|

Pallet Cleaner AQ-601 specification: |

|

|

Model |

AQ-601 |

|

Clean Basket Size |

Diameter 1000mmX200mm(H)mm |

|

Max Product Size |

Max 500mm(L)X300mm(W) |

|

Cleanging liquid Tank Capacity |

Max 80L |

|

Rinsing liquid Tank Capacity |

Max 80L |

|

Cleaning method |

Spray rotary cleaning and rinsing |

|

Drying method |

Heating air knife drying |

|

Cleaning Time |

5~20Minutes (Reference) |

|

Rinsing Time |

2-3Minutes (Reference) |

|

Drying Time |

10~20Minutes (Reference) |

|

Filtering method |

3-level filtering |

|

Level 1, 2 filtering |

2um(filter impurities ) |

|

Level 3 filtering |

5um(filter Filter flux, rosin, etc.) |

|

Dryer |

3.7KW, heating to 80℃ |

|

Electrical pump |

2.2KW |

|

Diaphragm pump |

1”pneumatic pump for liquid pumping, drainage. |

|

Air Supply |

0.5Mpa~0.7Mpa, 600l-800l/min |

|

Power Supply |

3Phase 380V 50/60HZ |

|

Power |

Max 28KW |

|

Net Weight |

500Kg |

|

Machine Size |

1380(L)×2100mm(W)×1400mm(H) |

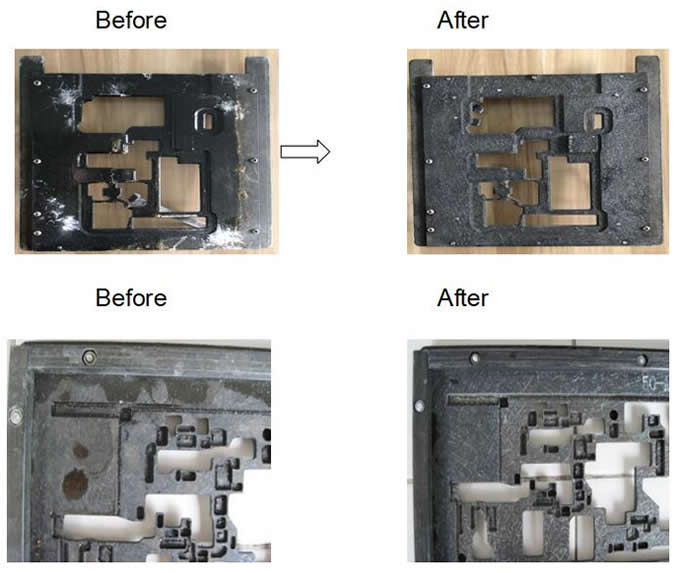

| Pallet Cleaner AQ-601 Application : |

|

0 review for Donec eu furniture

Related Products

ZQ-6800I Inline PCBA Cleaning Machine

- Model: ZQ-6800I

Pneumatic Scraper And Misprinted PCBA Cleaner PSC-600

- Model: PSC-600

Offline PCBA Cleaner AQ-650

- Model: AQ-650

Vertical Cleaner for Stencil & PCBA VSP-870

- Model: VSP-870

Add a review

Your email address will not be published. Required fields are marked