- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

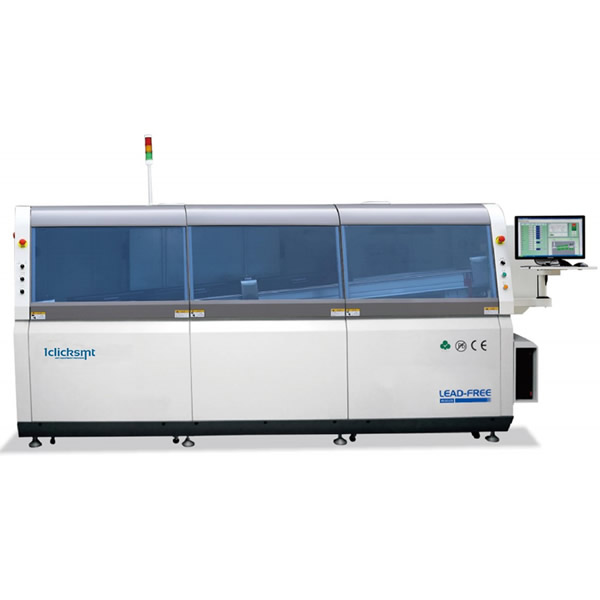

Power Wave Series Lead Free Wave Soldering Machine

Conveyor system adopts the stepless electronic speed governing and closed loop control system which allows a stable and accurate performance.

Available Options

Power Wave Series Lead Free Wave Soldering Machine

×|

|

● Conveyor system adopts the stepless electronic speed governing and closed loop control system which allows a stable and accurate performance. ● The inlet conveyor was equipped with a special pressure-device which is to prevent the PCB entrance slip. ● Used the double buckle chain to improve the bearing ability and loading stable and allows 50kg full loading stable and allows 50kg full loading. ● Equipped with the "L" or "V type of Ti finger in a staggered way to make the conveyor adapt the heavy PCB and light PCB. |

|

|

|

● Spray Nozzle driving by stepper motor will be Guided speeding and frequency according to the PCB width. ● The nozzle is right angle according to rail always to ensure the flux can good penetrate the PCB through holes. |

|

|

|

● Modularization High efficiency pre-heater is convenience for maintenance. attained powerful heat and long life. |

|

|

|

● The adjustable Micro-Wind Circulation Design. ● With independent temperature control in 3 Pre-heating Zones that can ensure to achieved the best heat-efficiency. ● Hot air and IR are available for arbitrary collocation. |

|

|

|

● Standard Durable cast iron solder pot for lead-free Production. ● Titanium solder pot is optional. ● High power Mechanical pump to ensure stable wave. |

|

|

|

● Solder Pot in/out and up/down driven by motorized system with security device to avoid any damage cause of incorrect operating. |

|

|

|

● Compelling Cooling System to attain the great cold-down slope as per lead-free required; ● Conveyor angle can easily be adjusted by manual. |

|

|

|

● Win 10 OS with Intellectronics Design, English Language on-screen is most convenience for operating. |

|

|

|

● Optional external sprayer scheme can be adopted, which is fireproof, safe and easy to maintain. |

|

|

|

||

Power Wave Lead Free Wave Soldering Machine Specification: | ||

Model | PowerWave-180/35 | PowerWave-180/45 |

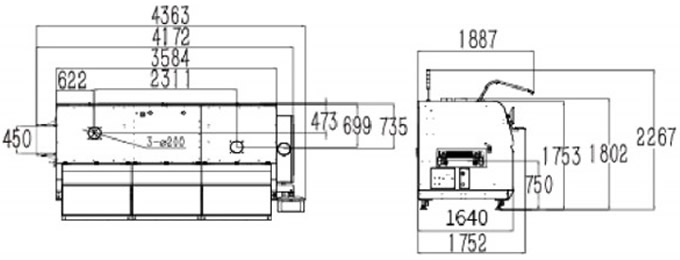

Dimension | L4160*W1550*H1760mm | |

PCB Conveyor Direction | L-R(OptionR-L) | |

Power Supply | 3P, 380VAC5O/6OHZ | |

Power Required | 80KW | |

Air Sources Required | 0.3-0.6MPa | |

Starting Power | 36KW | |

Normal Working Power | 7.3-10KW | |

Control Mode | PC + PLC | |

Preheating Model | Standard: Hot air, Option:IR | |

Adjust Mode on Preheat Blower | By Variable Frequency Regulating | |

No. of Preheat Zone | 3 | |

Length of Preheat Zone | 1800 mm | |

Preheat Temperature | Room Temperature--280℃ | |

Preheat Temperature Control | PID + SSR mode | |

Wave Moving Mode | Motor Drive | |

Solder Pot Heater Power | 1.2KW* 12 | |

Solder Pot Capacity | Standard: 520 KG with Cast Iron Solder pot, Option: 550KG with Titanium Solder pot | |

Solder Pot Max. Temperature | MAX:300℃ | |

Solder Usual Temperature | MAX:280℃ | |

Solder Pot Temperature Control Mode | PID + SSR mode | |

Wave Drive Power | l/2HPx2 3P220V | |

Wave Height Adjustment | By Variable Frequency Regulating | |

Wave width | 350mm | 450mm |

Solder Pot Warmup Time | Approx. 150min(Setting 250*C) | |

PCB Conveyor Speed | 300-1800mm/Min | |

PCB Width Range | 50-350mm | 50-450mm |

Component Height | TOP:120mm/ Bottom:25mm | |

Inlet Conveyor Height | 750±20mm | |

Conveyor Rail Angle | standard 4-7 degree Adjustable | |

Conveyor Motor Power | 90W, 3P220v, AC | |

Conveyor Motor Speed Adjustment | By Variable Frequency Regulating | |

FLUX Auto Refill | Standard | |

FLUX Flow | 10-100ml | |

Spray Air Pressure | 0.25-0.4MPa | |

Extraction Fan | 380V AC 375W | |

Extraction Pipe Diameter | Diameter: 200mm | |

Forced Air Fan | 380V AC 375W | |

Air Cooler | Option | |

Exhaust volume | 15m3/min | |

Power Wave Lead Free Wave Soldering Machine Options: |

● Titanium alloy solder pot |

● Top forced convection preheating zone |

● Top IR preheating zone |

● Reserved Nitrogen pipe with Oxegen analyser |

● Automatic width adjustment |

● Central support |

● Automatic solder adding device |

0 review for Donec eu furniture

Related Products

Lead Free Wave Solder Machine E400

- Model: E400

Add a review

Your email address will not be published. Required fields are marked