- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

Juki RX-6R

Improued Flexibility -Machine heads can be configured for high mix production WIth the new designed RX-6R placement speed is improved 24% from previous design. Juki is commotted providing a high speed, high quality flexible solution. Chip component Placement speed 52,000 CPH(Optimum)※. Placement speed is increased by 24% compared with the exsiting model. Compact footpringt: the width is juts 1.25m. Wide range of components and boards: tall compoenets and large boards.

Available Options

Juki RX-6R

×|

1.High Quality |

|

|

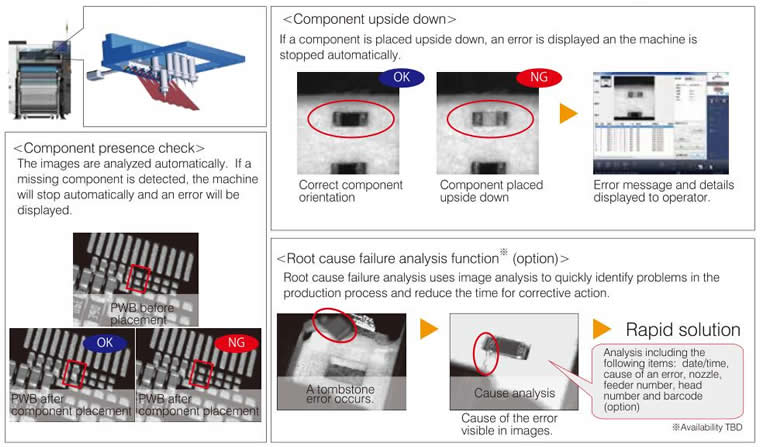

Prevent defective PWBs and support rapid cause analysis to provide corrective action |

|

|

An ultra-miniature camera built into the head section captures component pick-and-place images in real time. An analysis is run for presence/absence and traceability information can be temporarily saved. This unique function prevents defective PWBs and reduces the time for root cause failure analysis. |

|

|

|

|

|

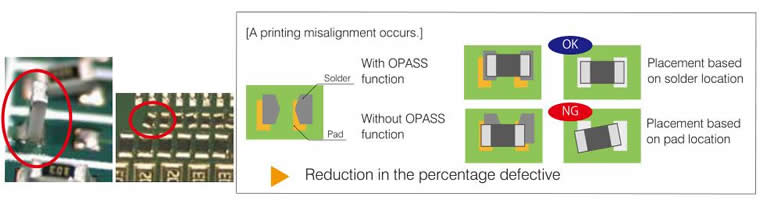

Reduce errors due to solder paste alignment(Offset Placement After Solder printing) |

|

|

The OPASS function uses the machine's downward looking camera to check the location of solder paste vs. the pads and corrects the placement accordingly. This function reduces defects caused by misalignment of the paste on the pads. |

|

|

|

|

|

Incorrect component prevention (Component Verification System (CVS)) |

|

|

By measuring the resistance, capacitance, or polarity before production starts, the machine can prevent incorrect components from being placed. The new CVS unit can check six components simultaneously, reducing the check and changeover times. |

|

|

|

|

2.High Productivity |

|

|

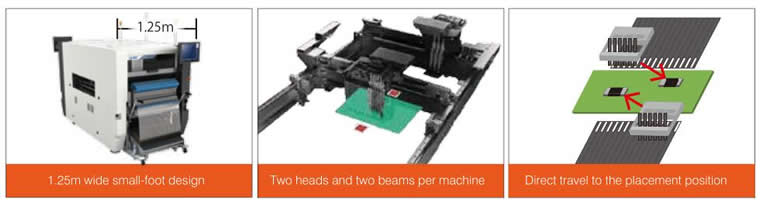

Machine construction for high-speed component placement and small-footprint design |

|

|

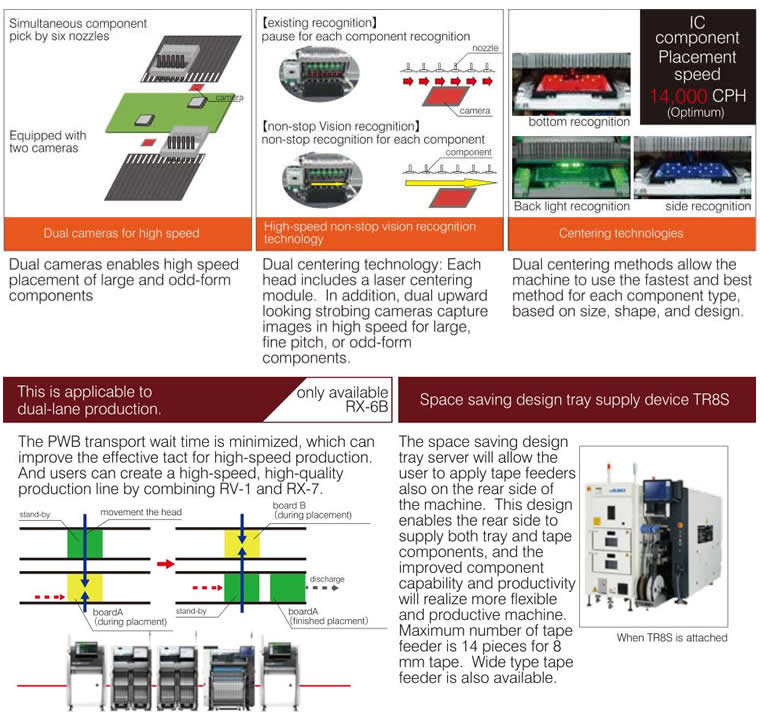

High-speed component placement in a very compact footprint: 1.25-mm wide Each machine is equipped with two heads, each with its own laser sensor. Components are centered in-flight between the pick and placement locations. Direct travel between the pick and placement position enables high speed placement with great accuracy. |

|

|

|

|

|

Vision recognition technology for high-speed component placement |

|

|

|

|

|

3.High Flexibility |

|

|

Wide component range |

|

|

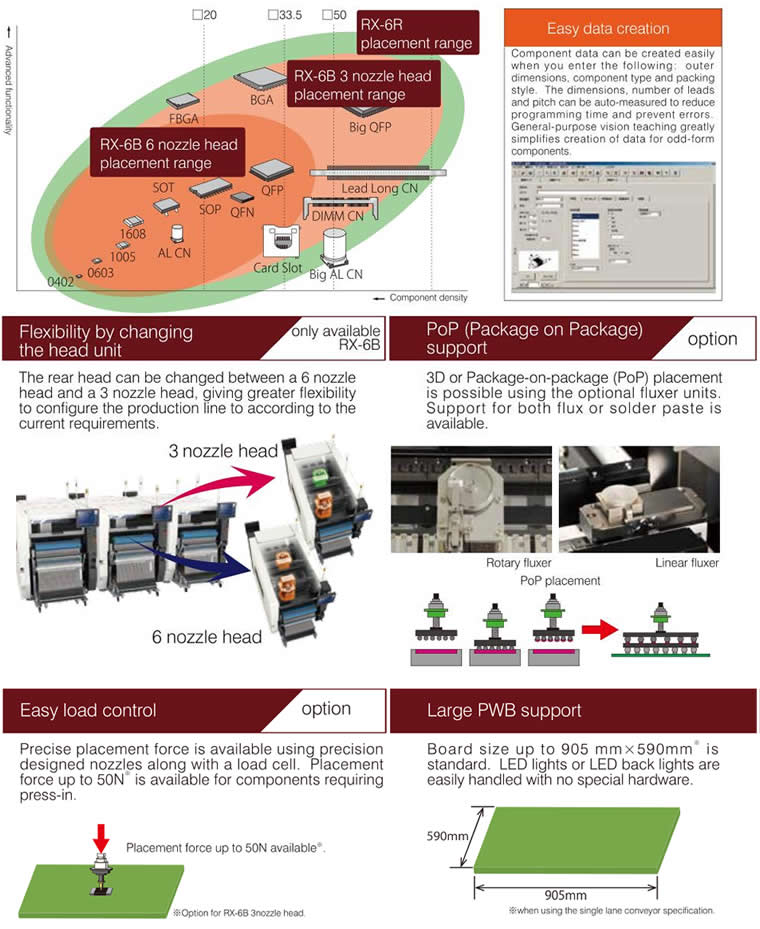

RX-6R supports components from 0402 (01005) up to 100mm squarer 50×180㎜ long connectors. RX-6B 6 nozzle head configuration can support from 0402 (01005) chips up to 50mm square, 3 nozzle head supports from 0402 to 100mm or 50mm×180mm long connectors. furthermore, RX-6B supports component height 33mm, it can support tall components ex. aluminum electrolytic capacitor. RX-6R is designed to handle a wide variety of components from ultra miniature resistors to large ICs or connectors. |

|

|

|

|

|

4.JUKI Basic Technology |

|

|

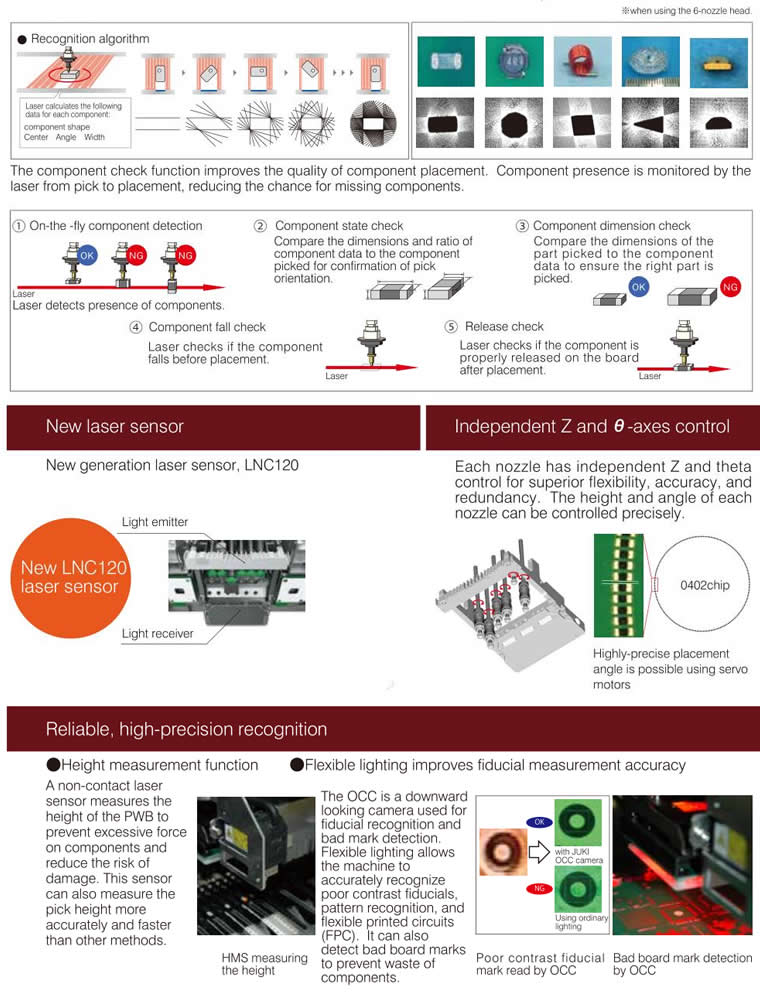

JUKI is proud to offer laser centering technology for high speed, accurate placement. |

|

|

The machine can recognize components of various shapes: from an ultra miniature components such as 0402 (01005) chips up to 50mm ※ square components such as PLCCs, SOPs, BGAs, and QFPs. When the machine recognizes a component with laser, variations such as shape, color, and reflection do not matter. |

|

|

|

|

|

High-Speed Compact Modular Mounter RX-6R Specification |

|||||

|

Model |

RX-6R |

RX-6B |

|||

|

Item |

6×6 nozzle head |

6×6 nozzle head |

6×3 nozzle head |

||

|

Board size |

Single lane conveyor | 50×50~610×590/905×590mm(2times clamping) | |||

| Dual lane conveyor | - | 50×50~360×250mm ※1 | |||

|

Component height |

6/12/20mm |

6/12/20/25/33mm |

|||

|

Component size |

Laser recognition | 0402(01005)~50mm | 0402(01005)~50mm | 0402(01005)~33.5mm | |

| Vision recognition ※2 | Standard camera | 3~100mm /50×180mm | 3~33.5mm | 3~100mm/50×180mm | |

| High-resolution camera | 1005~48mm/24×72mm | 1005~20mm | 1005~48mm/24×72mm | ||

|

Placement speed |

Chip | Optimum ※3 | 52,000CPH | 42,000CPH | 34,000CPH |

| IPC9850 | 29,000CPH | 26,000CPH | 23,000CPH | ||

| IC ※4 | 14,000CPH | 14,000CPH | 11,000CPH | ||

|

Placement accuracy |

Laser recognition | ±0.04mm(Cpk≧1)※5 | ±0.04mm(Cpk≧1) | ||

| Vision recognition※2 | ±0.04mm | ±0.04mm | ±0.03mm | ||

|

Component loading quantity |

Max.160 in case of 8mm tape(on a Electric double tape feeder) |

||||

|

Power supply |

200~415VAC, 3-phase |

||||

|

Apparent power |

40° |

||||

|

Operation air pressure |

40° |

||||

|

Air consumption |

+/-1 |

||||

|

Machine dimensions(W×D×H)※6 |

Yes |

||||

|

Mass(approximately) |

1680-2800RMP |

||||

|

※1. Single lane conveyor specification mode max 360 × 450 mm. |

|||||

|

※2. Option. |

|||||

|

※3. When using the single lane conveyor specification. |

|||||

|

※4. Placement speed of IC components is estimated value when placing 36 pieces QFP component (dimension 10mm square or smaller) on M size PWB overall,picking from both front and rear side with all nozzles simultaneously. |

|||||

|

※5. Under the JUKI condition |

|||||

|

※6. Machine width measure (D) does not include display. Machine height measure (H) does not include signal light and display. |

|||||

|

RX-6R Options |

|||

|

Recognitions system |

High-resolution camera(27mm view camera)/Component recognition Camera(VCS)(54mm view camera) |

||

|

Oparations system |

Rear-side operation unit |

||

|

Inspection function |

Coplanarity sensor/Component Verification System(CVS)/SOT detection check function |

||

|

Conveyor |

Conveyor extention |

||

|

Electrical protection |

Ground-fault interrupter |

||

|

Force Contol |

Force control nozzle |

||

|

Others |

Offset placement after solder screen-printing Solder lighting/FCS calibration jig/Mini signal light tower/ Super foot/Placement monitor Inspection function ※1/Fluxer unitLiner Type) /Rotary Type Caster/Nozzle |

||

|

Software |

IS ※2※3/IS Lite ※3/IFS-NX ※3/EPU |

||

|

Component handling and feeders※4 |

Feeder Trolley/Electric tape feeder/Electric stick feeder/High Speed Matrix Tray Server TR7DN/Matrix Tray Server TR8S/Tray Holder/IC collection belt/Trash box/Tape reel mounting baseFeeder trolley/Feeder stocker/Splicing jig/Feeder Calibration Jig with MonitorTray holder /Electric Trolley Power Station/Auto tape cutter |

||

|

※1. Only available for RX-6B 6 nozzle head. |

|||

|

※2. Supported only with a single lane conveyor specification. |

|||

|

※3. Availability TBD. |

|||

|

※4. Component handling and feeders are Electronic type only. |

|||

|

※Please refer to the product specifications for details. |

|||

0 review for Donec eu furniture

Related Products

Advanced Flexible Mounter CM-S8

- Model: CM-S8

High Speed LED Mounter CM-S36

- Model: CM-S36

Juki RS-1

- Model: RS-1

Flexible placer SM481 PLUS

- Model: SM481 PLUS

Odd shape component placer SM451

- Model: SM451

Add a review

Your email address will not be published. Required fields are marked