- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

Juki RX-7

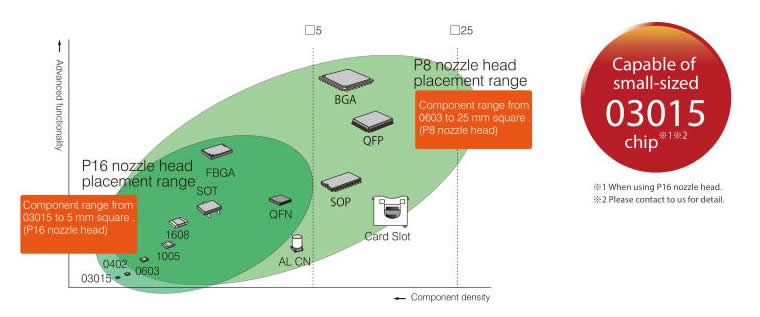

The next-generation high density placement Production line productivity is improved due to the combination of a planet head that provides optimum productive capacity, based on the parts to be placed and the configuration of a flexible production line. Space-saving design with a width of 998 mm. This is applicalbe to the dual lane production. An optimum production line can be configured for each production item through a combination of heads. High productivity based on an original planet head and a structure of parallel two heads This is applicable to small-size IC components ranging from o3o15 chip to 25mm square to be placed.

Available Options

Juki RX-7

×1. JUKI base technology | |

Basic Technology: Planet head technology realizes high speed and a high quality | |

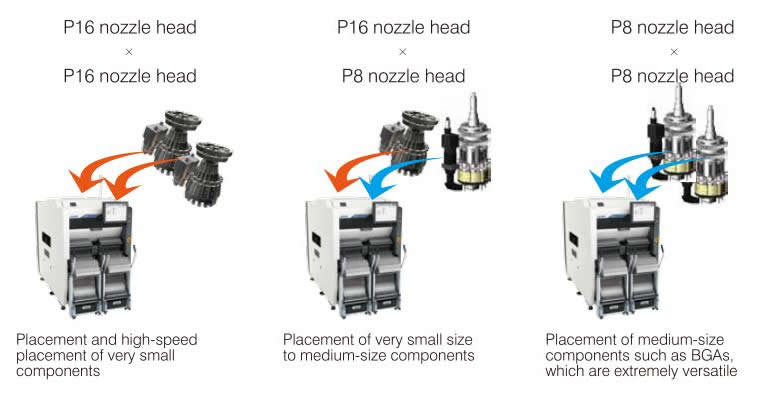

Owing to a structure with two parallel heads that is free from mutual interference between mounted heads, the maximum throughput can be realized. For a placement head, users may select between the two types of planet head, namely, P16 nozzle and P8 nozzle. The original lightweight compact planet head technology provides high-speed, high-quality and high-accuracy placement. | |

| |

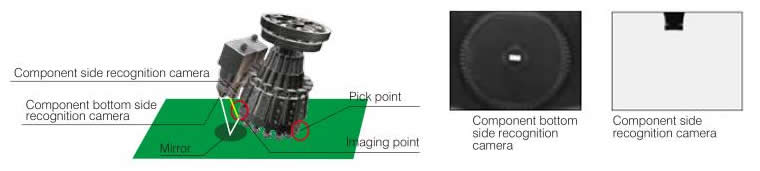

Basic Technology: P16 nozzle head that realizes high-speed high-density placement of very small components | |

Regarding the P16 nozzle, the Z-axis stroke at component pick and component placement can be minimized by inclining the head's rotary axis. The two cameras incorporated in the head unit can recognize component thickness and weight with high accuracy. High-speed and high-accuracy placement at a placement speed of 75,000 CPH (optimum condition) and a component placement accuracy of ±0.04 mm (Cpk ≧ 1) is realized. | |

| |

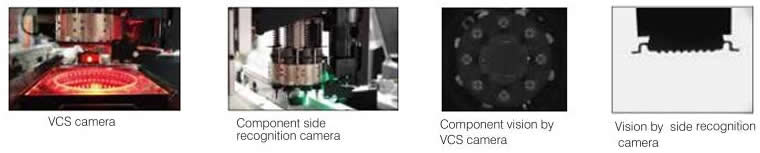

Basic Technology: P8 nozzle head that realizes high-speed and high-accuracy placement of middle and small general-purpose components | |

The P8 nozzle head can place components ranging from very small chip components to small and medium general-purpose components. High-speed and high-accuracy placement can be realized with high-accuracy overall vision recognition using a VCS camera. This can also perform component reverse inspection and component existence/non-existence inspection in the same way as the P16 nozzle head. | |

| |

2. High Productivity | |

Flexibility: Wide component range | |

The P16 nozzle head is applicable to very small components with a size of 03015 to 5 mm square and the maximum height of 3 mm. The P8 nozzle head is applicable to components with a size of 0603 to square25 mm and the maximum height of 10.5 mm, for example, small IC components such as QFP andBGA.These two types of planet head can provide the highest performance for various production needs. | |

| |

Flexibility: By combination of head, various production be available to flexible production line | |

Users may select an optimum head according to production items and components to be placed. A combination of the P16 and P8 nozzle heads and a production line configuration allow a mass production line for smart phones and a high-speed placement line for various production items. The performance of the machine itself and a line balance of the whole placement line is improved, thereby increasing productivity. | |

| |

3. High Quality | |

Productivity: Space-saving design with a width of 998 mm | |

Super-slim 998mm width! At 75,000 CPH, the RX-7 provides excellent placement per square foot. | |

| |

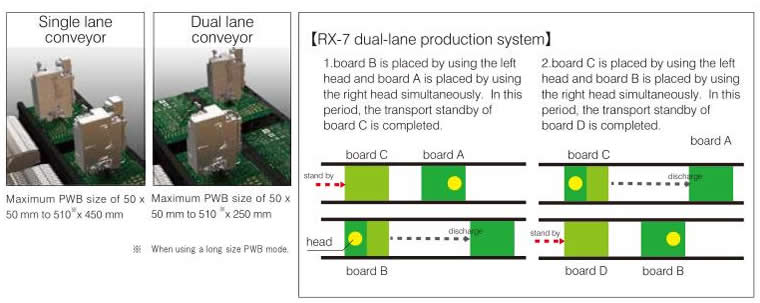

Productivity: This is applicable to dual-lane production | |

This dual-lane transport system comes as standard. The PWB transport wait time is minimized, which can improve the effective tact for high-speed production. | |

| |

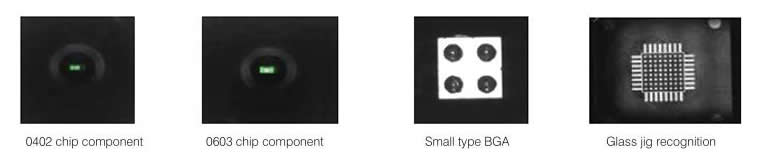

Productivity: High-accuracy placement using new-structure camera recognition | |

Clearer imaging can be performed with the recognizing technology using new-structure coaxial lighting. As a result, high-accuracy placement recognition can be realized. | |

| |

4. High Flexibility | |

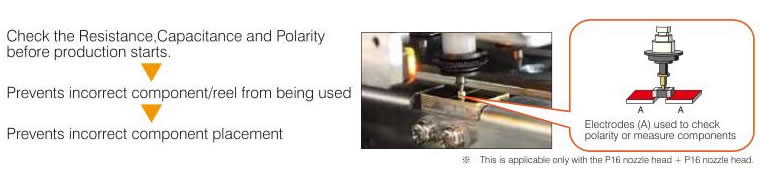

Quality: Component Verification System(CVS) | |

By measuring the resistance, capacitance, or polarity before production starts, the machine can prevent incorrect components from being placed. | |

| |

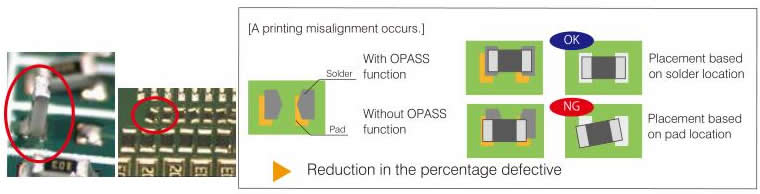

Quality: Reduce errors due to solder paste alignment (Offset Placement After Solder printing) | |

The OPASS function uses the machine's downward looking camera to check the location of solder paste vs. the pads and corrects the placement accordingly. This function reduces defects caused by misalignment of the paste on the pads. | |

| |

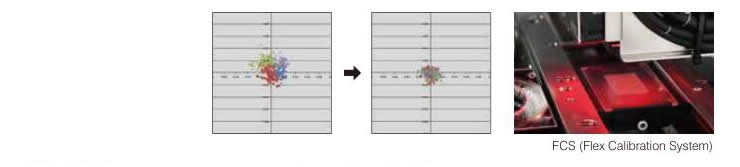

Quality: FCS (Flex Calibration System) | |

JUKI's highly regarded easy maintenance just got even easier! The optional FCS calibration jig is a simple to use system to re-calibrate placement accuracy. The machine automatically picks and places jig components, then measures the error and adjusts all necessary calibrations. (optional) | |

| |

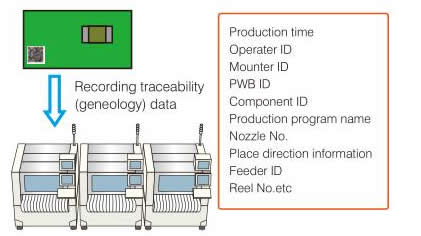

Quality: IFS-NX(Intelligent Feeder System) | |

The Intelligent Feeder System (IFS-NX) option provides enhanced setup control by verifying part barcodes to smart feeders. Traceability to the refer- ence designator level is available as an option. Other functions include inventory tracking, and feeder setup assistance. |  |

High -Speed Compact Modular Mounter RX-7 Specification | ||||

Model | RX-7 | |||

Item | (P16×P16 nozzle head) | (P16×P8 nozzle head) | (P8×P8 nozzle head) | |

Board size | Single lane conveyor | 50×50~510mm ※1×450mm | ||

| Dual lane conveyor | 50×50~510mm ※1×250mm | |||

Component height | 3mm | 3mm(P16 nozzle head)10.5mm(P8nozzle head) | 10.5mm | |

Component size | 03015 ※2~5mm | 03015 ※2 ~5mm (P16 nozzle head) | 0603(0201)~25mm | |

| 0603(0201)~25mm (P8 nozzle head) | ||||

Placement speed | Chip(Optimum) | 75,000 CPH | 54,900CPH | 34,800CPH |

| IC | - | 6,400CPH ※3 | 12,800CPH | |

Placement accuracy | Chip | ±0.04 mm(Cpk≧1) | ||

| IC | - | ±0.04 mm | ||

Component loading quantity | 38(76 in case of 8mm tape)※4 | |||

Power supply | AC200V-430V, 3-phase | |||

Apparent power | 3.3kVA | |||

Operation air pressure | 0.5±0.05MPa | |||

Air consumption (standard) | 20L/min(during normal operation) | |||

Machine dimensions (W×D×H)※6 | 998×1,895×1,530mm | 998×1,895×1,530mm ※5 | ||

Mass (approximately) | 1,950kg | |||

※1. When using a long size PWB mode. | ||||

※2. Please contact to us for detail. | ||||

※3. This is applicable only to the P8 nozzle head. | ||||

※4. When a double lane feeder is used. | ||||

※5. In the case of the P8 nozzle head specification, the feeder is set at 123mm ahead in comparison to the P16 nozzle head. | ||||

※6. The depth (D) of external dimensions applies only when the display is excluded, and the height applies when the transport height is 900mm, excluding the display. | ||||

RX-7 Options | |||

Conveyor | Support-pin / Support-sponge | ||

Inspection function | Component Verification System (CVS) ※ | ||

Others | Dedicated nozzle/Spare nozzle cartridge/Joint cable/Offset placement after solder screen-printing | ||

Software | Line control soft IS-Lite/IFS-NX(Parts verification/Traceability/component inventory control) | ||

Component handling and feeders | Feeder Trolley/Electric tape feeder/Tape reel mounting base/Feeder stocker/Splicing jig/Feeder Calibration Jig with MonitorTray holder/Electric Trolley Power Station | ||

※ Please contact JUKI for more information about P8 nozzle head application time. | |||

RX-7 Line Control Software | |||

Product name | Major functions | ||

IS Lite | User definition/Facility definition/Component DB/Creating production programs/Line optimization Line monitoring/CAD conversion ※ /Cluster optimization | ||

※ CAD conversion is optional. | |||

RX-7 Security software | |||

Virus measurement software | White list (standard) | ||

※ Please refer to the product specifications for details. | |||

0 review for Donec eu furniture

Related Products

Advanced Flexible Mounter CM-S8

- Model: CM-S8

High Speed LED Mounter CM-S36

- Model: CM-S36

Juki RS-1

- Model: RS-1

Flexible placer SM481 PLUS

- Model: SM481 PLUS

Odd shape component placer SM451

- Model: SM451

Add a review

Your email address will not be published. Required fields are marked