- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

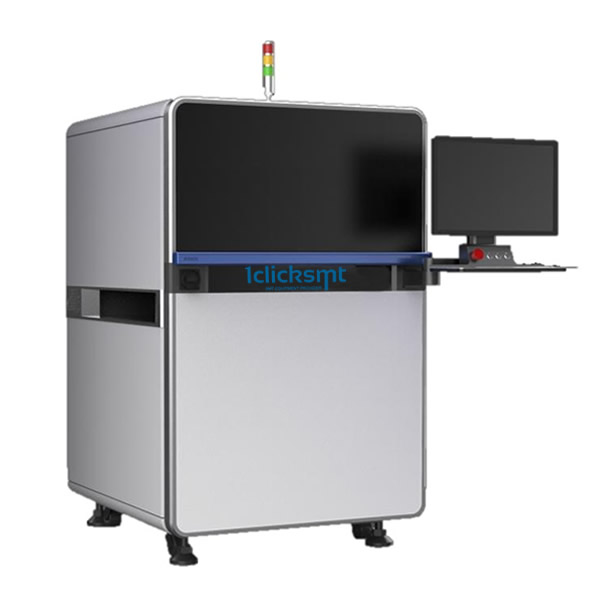

SA-500 SMT Component Automated Inspection System

SA-500is a AOI equipment for SMT component inspection and chip component inspection. SA-500uses intelligent algorithm which can just click one button for programming, it greatly reduce the programming and debugging work, AI deep learning and self-training function can extend detectable defect types to reduce the misjudgement rate.

Available Options

SA-500 SMT Component Automated Inspection System

×|

SMT Component Automated Inspection System Features |

|

● High stability granite platform ensure machine running fast and stably. |

|

● X/Y servo motor with high precision ball screw driving system ensures running accuracy. |

|

● Equipped with 5M pixels CCD with RGBW 4 color light source to ensure inspection accuracy. |

|

● Detection items: Chip components: Wrong, Miss, Reversed, Skew, Redundant, shift, foreign matter. Solder detect: excess, insufficient, no foot, bridge, not wetting. |

|

● Easy programming: Use Intelligent algorithm which can automatically search chip components and solder joint on the PCB image without CAD files, and give the parameters, operator only need to fine-tune the program, it makes programming very easy. |

|

● Intelligent algorithm: Intelligent neural network algorithm which can train the components with large sample images to comprehensively recognize the features of the components to improve the misjudge problems, and make programming easy. |

|

● Equipped with Data statistics software, easy to search and export detailed statistical data. |

|

● Capable to connect with MES(option). |

|

SMT Component Automated Inspection System Specifications |

|||

| Model | SA-500 | SA-500D | |

| Image System | Camera | Top 5 Mpixels CMOS Camera | Top 5 Mpixels CMOS Camera |

| Resolution | Standard :15um , optional : 10um | Standard :15um , optional : 10um | |

| FOV size | 15um : 36*30mm, 10um :24*20um | 15um : 36*30mm, 10um :24*20um | |

| Lighting | 4 color ring shape LED(RGBW) | 4 color ring shape LED(RGBW) | |

| Motion System | X/Y Movement | AC Servo motor | AC Servo motor |

| Platform | Granite, ball screw and linear rail. | Granite, ball screw and linear rail. | |

| With adjustment | Auto/Manual | Auto/Manual | |

| Flow Direction | L→R | L→R | |

| Hardware | PC configuration | Intel I5 CPU, 32G DDR , 256G SSD +1T hard disk | Intel I5 CPU, 32G DDR , 256G SSD +2T hard disk |

| Communication | SMEMA | SMEMA | |

| Power Supply | 1ph 220V,50/60Hz , 1KW | 1ph 220V,50/60Hz , 1KW | |

| Air Supply | 0.4-0.6Mpa | 0.4-0.6Mpa | |

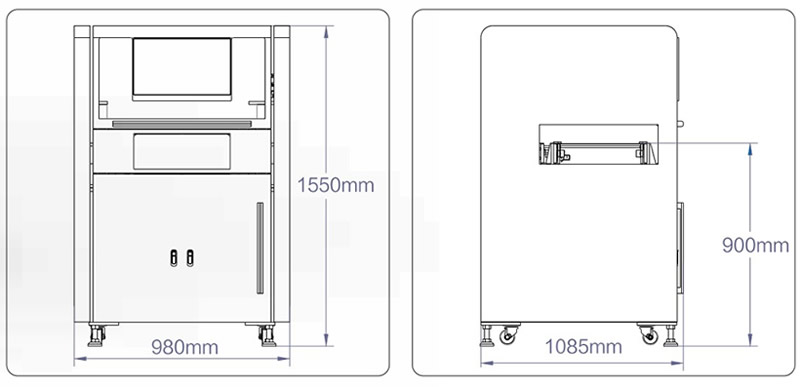

| Machine Size | L985*D1100*H1550mm(not including display and light tower) | L990*D1370*H1550mm(not including display and light tower) | |

| Weight | 700kg | 800kg | |

| Software | Operation System | Ubuntu 14.04 LTD 64bit | Ubuntu 14.04 LTD 64bit |

| Programming | Online programming , offline programming , CAD file loading , one-key programming with image | Online programming , offline programming , CAD file loading , one-key programming with image | |

| Statistic data function | SPC software | SPC software | |

| PCB Size | Size | 1 section rail : 50*50-520*460mm | 1 section rail : 50*50-510*330mm, double rail single rail : 50*50-510*610mm |

| Thickness | ≤6.0mm | ≤6.0mm | |

| Clearance | Top/Bottom:25/25mm | Top/Bottom:25/25mm | |

| Clamping Edge | >3.0mm | >3.0mm | |

| Inspection Catagories | Component | Missing,Reversed,Shift,Damaged,Skew ,Redundant,Foreign material | Missing,Reversed,Shift,Damaged,Skew ,Redundant,Foreign material |

| Solder | No solder,Insufficient/Extra solder,Bridge,not welding,no foot,Hole | No solder,Insufficient/Extra solder,Bridge,not welding,no foot,Hole | |

| Inspection Component | Chip:03015 and above LSI:0.3mm pitch and above | Chip:03015 and above LSI:0.3mm pitch and above | |

| Inspection Speed | 230-250ms/FOV | 230-250ms/FOV | |

| Barcode reader | 1D or 2D barcode reading by camera | 1D or 2D barcode reading by camera | |

|

SMT Component Automated Inspection System Dimension : |

|

Dimension of the SA-500 machine: |

|

|

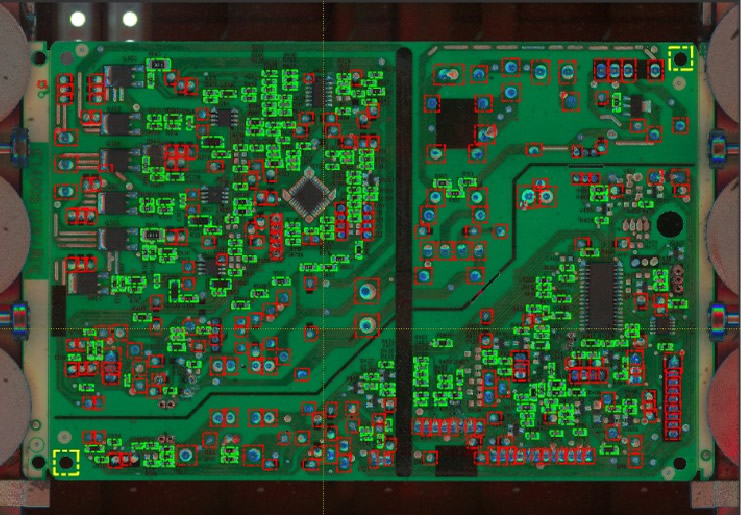

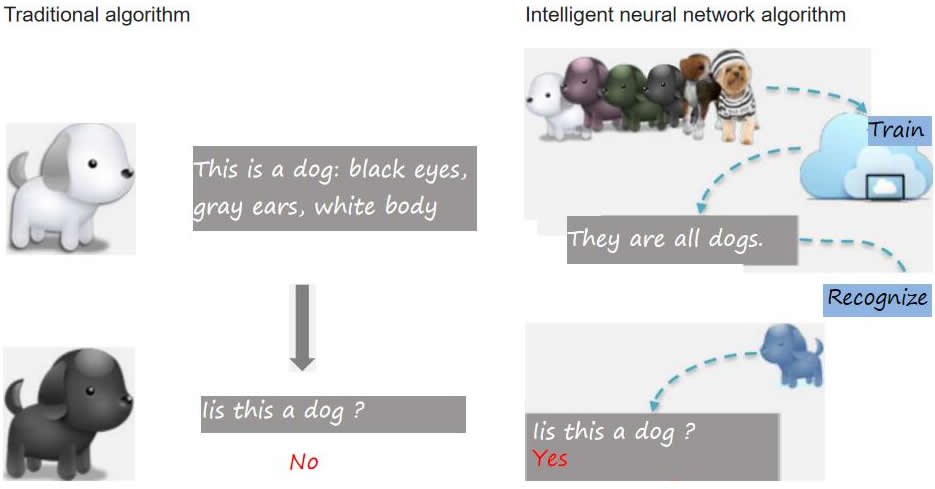

SMT Component Automated Inspection System Algorithm: |

|

Intelligent neural network algorithm: The traditional algorithm is mainly to compare the color of the reflected light of the soldering joint, and then to judge whether it has bad quality. In this case, the programmer is required to be experienced and familiar with the various forms of bad products. Neural network algorithm through the analysis of big data processing, can know the various forms of solder joints,and low requirements for the operator. |

|

|

SMT Component Automated Inspection System Algorithm: |

|

Intelligent algorithm also can train the components with large sample images to comprehensively recognize the features of the components to improve the misjudge problems. |

|

Priciple comparision with raditional algorithm |

|

|

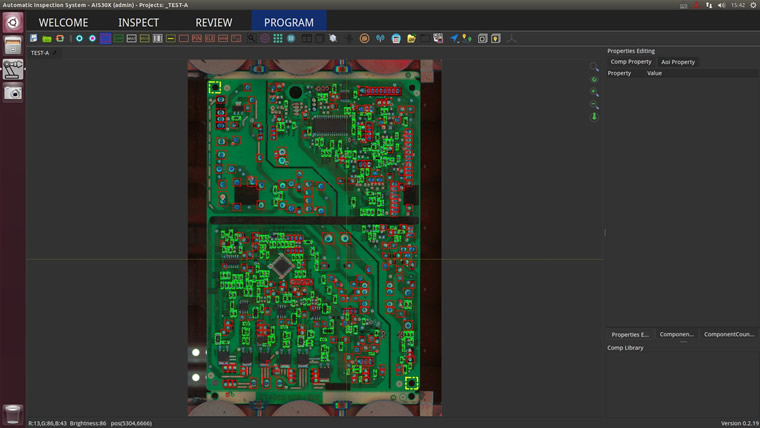

SMT Component Automated Inspection System Programming: |

|

Easy programming: Use Intelligent algorithm which can automatically search chip components and solder joint on the PCB image without CAD files,and give the parameters, operator only need to fine-tune the program, it makes programming very easy. |

|

|

SMT Component Automated Inspection System Software function: |

|

Path optimization:

Fewer FOVs : Do not photograph on where there is no solder joints to reduce FOVs and make inspection more efficient. More suitable imaging position : avoid solder joint at FOV junction to ensure test effect. |

|

|

SMT Component Automated Inspection System Software function: |

|

Multiple detection and debugging modes: ◆ Support panel board detection. ◆ Support mixed board detection, suitable for small-batch multi-PCB detection. ◆ Badmark skip mode. ◆ Online programming and debugging without stopping the production line. ◆ Offline programming (optional ). |

|

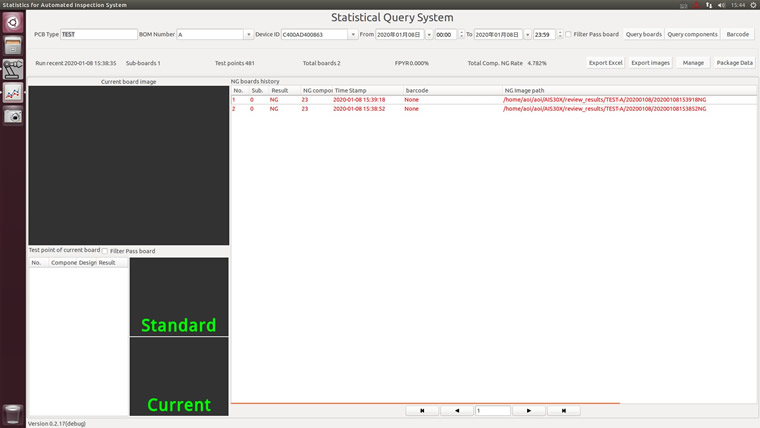

SMT Component Automated Inspection System Data statistic: |

|

Powerful data statistic software, easy to search and to be exported as a Exel file. |

|

|

SMT Component Automated Inspection System Includes: |

|

Standard configuration: |

|

1. SMT Component Automated Inspection System SA-500/SA-500D. |

|

2. Online programming software (combined with AOI software ). |

|

3. Data statistic software(combined with AOI software). |

|

Option configuration : |

|

1. Offline programming software. |

0 review for Donec eu furniture

Related Products

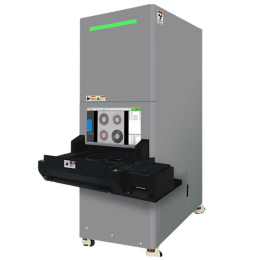

Merlin A-400P Offline Automated Inspection System

- Model: Merlin A-400P

Falcon SA-510F SMT Component Automated Inspection System With Flipper

- Model: Falcon SA-510F

X-Ray Counter SoYi-C3

- Model: SoYi-C3

X-Ray Counter SoYi-C2

- Model: SoYi-C2

S-350/S-600 Series Desktop SPI Machine

- Model: S-350/600

Add a review

Your email address will not be published. Required fields are marked