- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

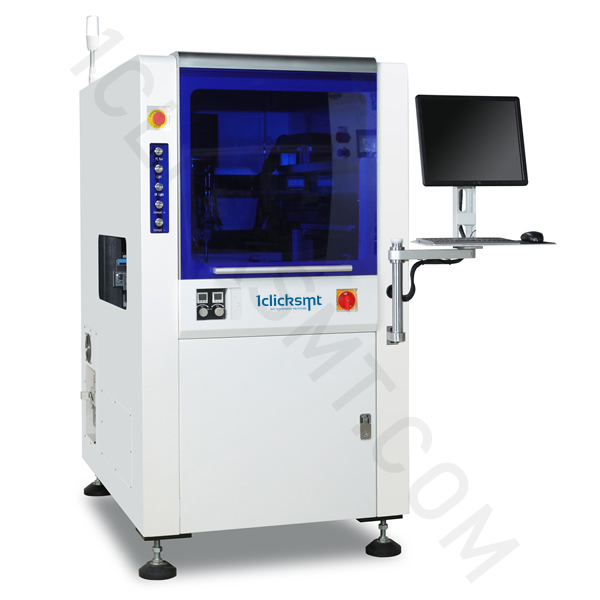

3 Axis Selective Coating Machine SC-800

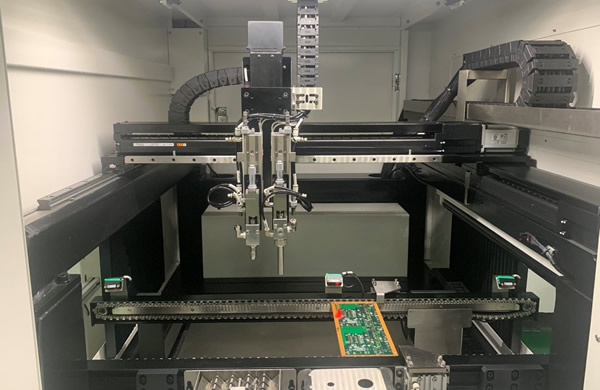

High Performance 3 Axis Selective Coating Machine SC-800 is equipped with high precision servo control system, various valves, CCD system, material tank weight detecting system etc, which can provide a high efficiency conformal coating process. The maximum coating size can reach 400mm*450mm with SC-800.

3 Axis Selective Coating Machine SC-800

×|

|

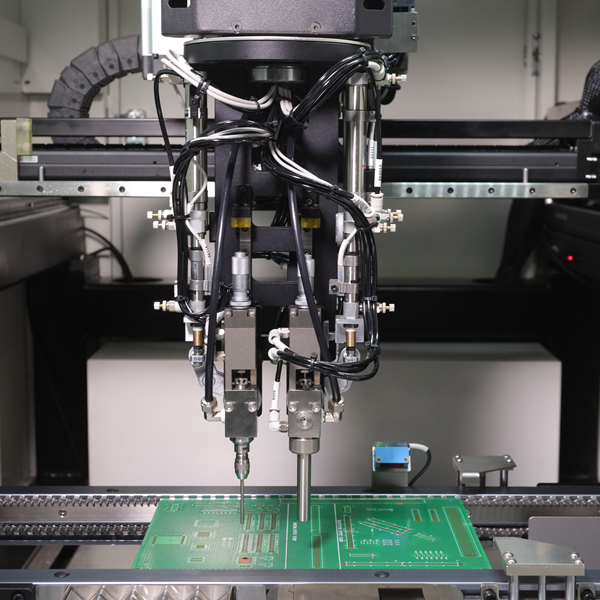

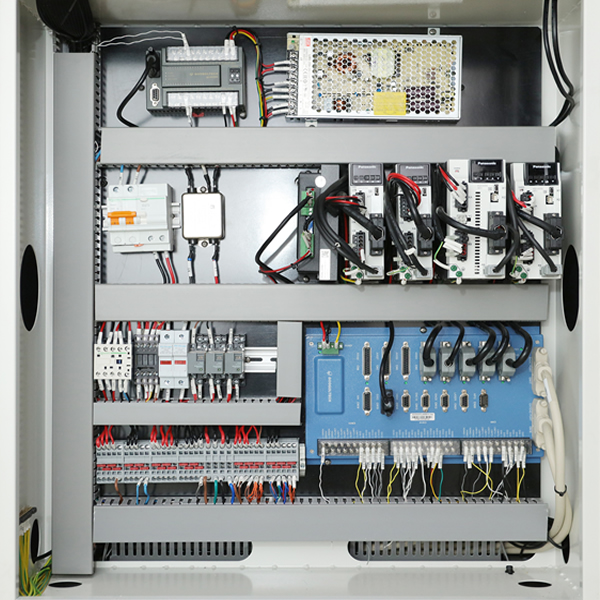

Machine adopt high strength welding frame, X/Y/Z/R axis adopt Panasonic servo motor and ball screw to ensure high speed and stable running. |

|

|

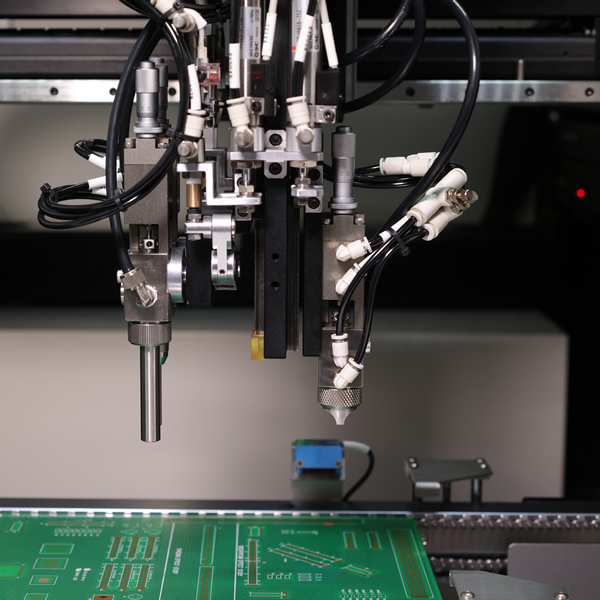

High precision valve with rotation and tilting device realize high precision coating with no dead ange. |

|

|

Glue weighing system can detect empty tank to avoid missing coating. |

|

|

High quality parts ensures long service life. |

|

|

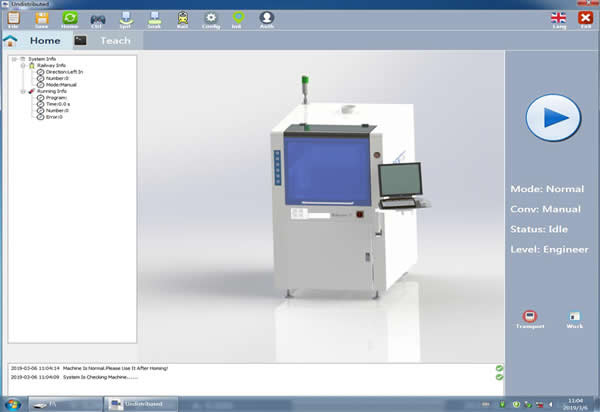

Professional coating software easily meet various requirement of coating prcoess. |

|

3 Axis Selective Coating Machine SC-800 Features : |

| 1. Machine adopt high strength welding frame, X/Y/Z axis adopt Panasonic servo motor and ball screw to ensure high speed and stable running. |

|

2. A variety of high precision valves can meet different coating requirements. |

|

3. Optional CCD system can be used for programming and mark recognition. |

|

4. Glue weighing system can avoid missing coating. |

|

5. Optional barcode reading system which can automatically call program according to barcode for double side coating line. |

|

6. Professional coating software easily meet various requirement of coating prcoess. |

|

7. Industrial PC, windows operation system, full english interface, very easy to use. |

|

8. Customized whole coating line is available. |

|

3 Axis Selective Coating Machine SC-800 specification: |

||

|

Model |

SC-800 |

SC-900 |

|

Machine stroke |

L400mm*W450mm, |

L400mm*W450mm, |

|

Axis number |

X/Y/Z axis |

X/Y/Z/R axis(+/-180 degree rotable ) |

|

Max Work Movement Speed |

Max 800mm/s |

Max 800mm/s |

|

Max installable valve quantity |

2 valves |

3 valves |

|

Standard Valve |

Narrow spray valve, Needle spray valve |

Narrow spray valve, Needle spray valve |

|

Optional valve |

Film coating valve, Wide spray valve |

Film coating valve, Wide spray valve |

|

Valve tilting device |

N/A |

narrow spray valve and needle spray valve with tilt angle 35° |

|

Max PCB Component Height |

70mm |

70mm |

|

Programming |

manual teaching by valve or CCD, load. dxf file |

manual teaching by valve or CCD, load. dxf file |

|

Repeatable Accuracy |

+/- 0.05mm |

+/- 0.05mm |

|

Conveyor Height |

920mm±30mm |

920mm±30mm |

|

Conveyor direction |

only left to right |

only left to right |

|

Conveyor Speed |

2~5M/min |

2~5M/min |

|

Conveyor width adjustment |

Motorized |

Motorized |

|

Material Tank |

10L |

10L |

|

Cleaning solvent tank |

2L |

2L |

|

PCB clamper |

Standard configuration |

Standard configuration |

|

Power Supply |

AC220V 50~60Hz |

AC220V 50~60Hz |

|

Total Power |

2KW |

2KW |

|

Air Requirement |

0.4-0.6Mpa |

0.4-0.6Mpa |

|

Overall Size W*D*H |

1000mm*1310mm*1700mm(not including display bracket) |

1000mm*1310mm*1700mm(not including display bracket) |

|

Weight |

550KG |

580KG |

|

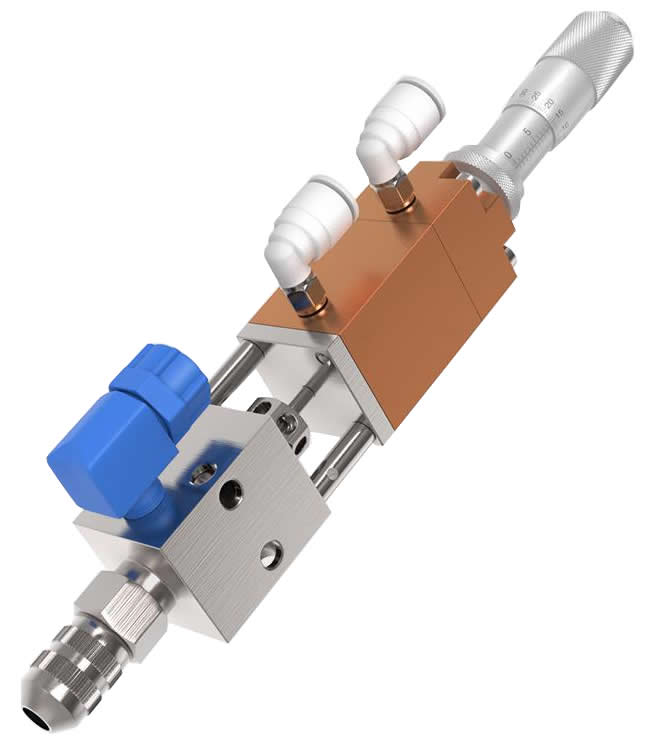

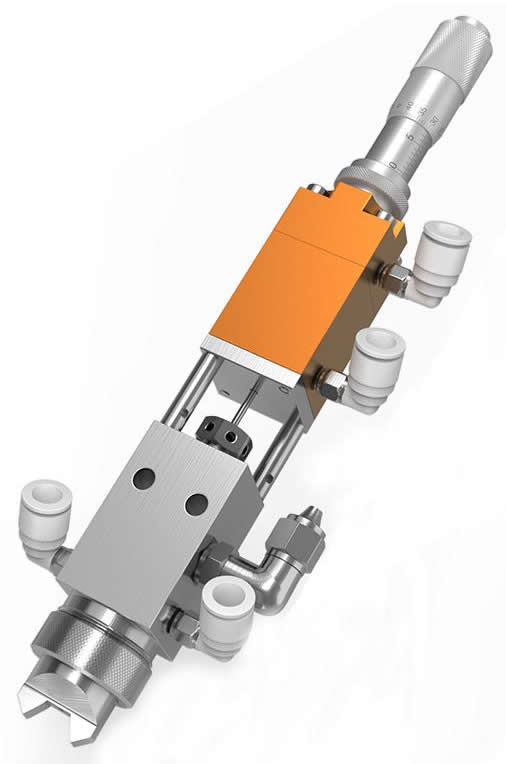

Needle Dispensing valve |

Needle Dispensing valve is applied to areas where: 1.components are close to keep-out areas. 2.tall component require support. 3.extra glue is required. 4.glue is needed on the edge or under a component. |

|

|

|

|

● Dispensing line width:min. 1.5mm ● Air pressure: Air pressure: 0.1-0.4Mpa ● Applied to max viscosity of the glue :500cps |

|

|

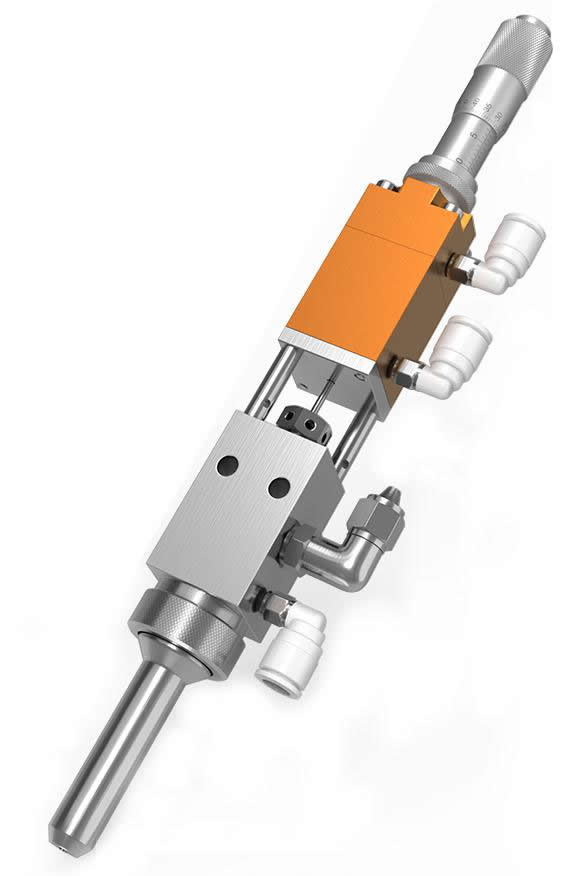

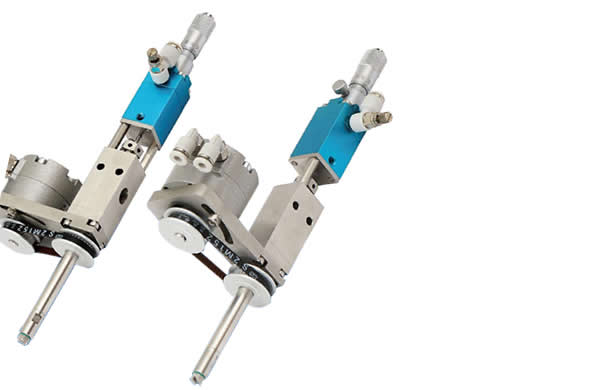

Narrow spray valve |

1. Coating thickness can be adjusted by changing air pressure and moving speed. 2. Coating width can be adjusted by changing air pressure. 3. Narrow spray valve is applied to areas where: 1.most of coating. |

|

|

|

|

● Spraying swath: 6-10mm ● edge definition : 2mm ● Air pressure: 0.2-0.4Mpa ● Applied to max viscosity of the glue :1000cps |

|

|

Wide spray valve |

● big spray swath ,high efficiency .Coating thickness can be adjusted by changing air pressure and moving speed. ● Coating width cand be adjusted by changing air pressure. ● wide spray valve is applied to areas where: 1.large coating area without barrier. |

|

|

|

|

● Spraying swath: 15-30mm ● edge definition : 3mm ● Air pressure: 0.1-0.4Mpa ● Applied to max viscosity of the glue :800cps

|

|

|

Film coating valve V-5000 |

Feature: 1.apply material as controlled film. 2.non-aotomized propulsion ,excellent selectivity and high transfer efficiency. 3.solvent coating material thickness can reach 0.05-0.2mm. 4.virtually eliminates masking through precise selective material applicaion. 5.Nozzle can rotate at 0, 90 degree. |

|

|

|

|

● Spraying swath: 8-10mm ● Air pressure :0.2-0.4Mpa ● Applied to max viscosity of the glue :100cps |

|

|

3 Axis Selective Coating Machine SC-800 Valve specification |

|||

|

Valve parameter |

Needle valve |

Narrow spray valve |

Wide spray valve |

|

spraying swath |

min dot size :1.5mm |

6-10mm |

15-30mm |

|

air pressure |

0.2-0.4Mpa |

0.2-0.4Mpa |

0.2-0.4Mpa |

|

applied to max glue viscosity |

500 cps |

1000 cps |

800 cps |

|

edge definition |

1 mm |

2 mm |

3 mm |

|

applied to |

1.components are close to keep-out areas. |

1.atomazation film can be adjusted by air pressure and moving speed ,applied to most of product. |

1.big spray swath ,highefficiency,applied to large coating area without barrier |

|

2.tall component require support. |

|||

|

3.extra glue is required. |

|||

|

4.glue is needed on the edge or under a component. |

|||

|

Standard Configuration |

|

● 3 Axis Selective Coating Machine SC-800 |

|

● Industrial PC, monitor, Keyboard, mouse. |

|

● X/Y/Z 3 aix driving system. |

|

● Narrow spray valve * 1pcs |

|

● Needle valve * 1pcs |

|

● 3 color alarm light |

|

● PCB clamper * 1set |

|

● 10L material tank * 1set |

|

● 2L cleaning tank * 1set |

|

● 1 year parts warranty |

|

Optional Configuration: |

|

● Film coating valve |

|

● Wide spray valve |

|

● Glue Tank mixing with vacuum |

|

● CCD with fiducial mark recognition system |

|

● Material tank weighing system |

|

● Bar code reader |

3 review for Donec eu furniture

allen - 2020-12-28 09:00:15

hello Your email address will not be published. Required fields are markedAllen - 2020-12-28 09:15:44

fwfgegAdd a review

Your email address will not be published. Required fields are marked

Related Products

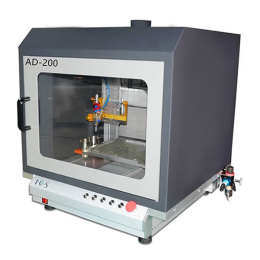

Benchtop Selective Coating Machine AD-200

- Model: AD-200

wspnet - 2020-12-26 06:20:17

Your email address will not be published. Required fields are marked