- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

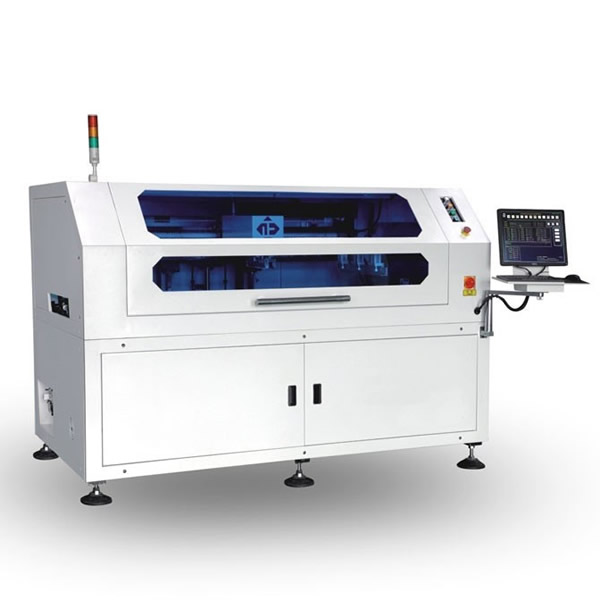

Fully Automatic Screen Printer H12 & H15

● Arch bridge type suspending direct-connected scraper, programmable printing head. ● Double sliders ensures the printing head moving accuracy and stability when scraper is running back and forth. ● Programmable motor controls conveying speed and conveys PCB in the precise position ● The cleaning unit is separated from CCD camera, which can minimize the load of motor, improve the positioning precision and speed. ● Automatic conveyor width adjustment. ● Auto stencil cleaning(Dry/Wet/Vacuum). ● Automatic 2D paste inspection.

Available Options

Fully Automatic Screen Printer H12 & H15

×

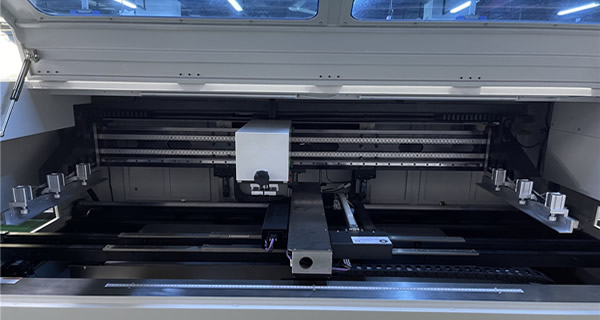

| Arch bridge type suspending direct-connected scraper programmable printing head. Double sliders ensures the printing head moving accuracy and stability when scraper is running back and forth. |

| The cleaning unit is separated from CCD camera, which can minimize the camera & stop axis load, improve the PCB positioning precision and speed. Stencil cleaning system is automatic and effective. Three models of Dry cleaning. Wet cleaning and Vacuum cleaning can be selected to use individually and multiply. |

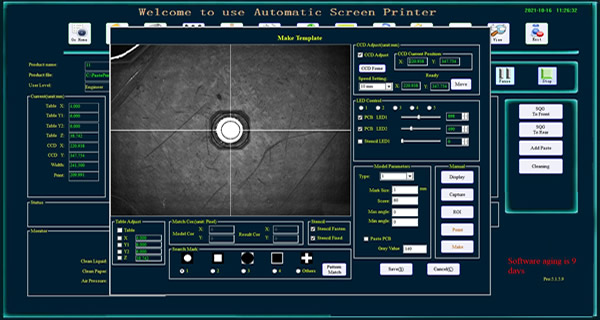

| Uniform ring light, high brightness coaxial light and advanced upper/lower visionsystem Full range of light compensation, Automatic and accurate recognized of alltype MARK points. Applicable for tin plating, copper plating, gold plating, tin spraying. FPC and other types PCB with different colors, able to ensure high accuracy. |

| Using Windows 10 operation interface, and easy to learn for user. Programming is designed with teaching and navigation function, guidance is available on every step. |

| High quality electrical parts ensure machine long service life. |

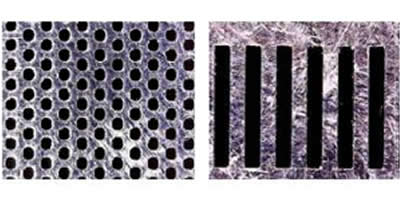

Stencil Cleaning System | |

3 types of under stencil cleaning: dry, wet and vacuum. These 3 modes can be individually selected or combined for using. System allows manual cleaning within its operation menu which shortens cleaning time and improves production efficiency. |

|

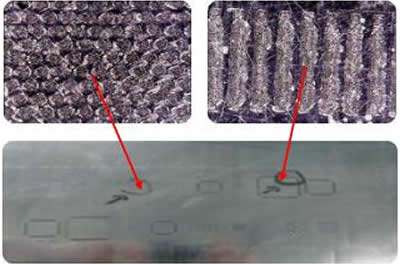

BEFORE CLEANING | |

Blocked the opening of stencil by solder paste and choose 2 areas (IC and BGA )to check cleaning result. |

|

CLEANING RESULT | |

Conclusion: blocked holes and IC can be cleaned completely. Customer could set up cleaning module (wet, dry and vacuum modes) depends on difficulty of stencil to improve productivity and ensure cleaning quality. |

|

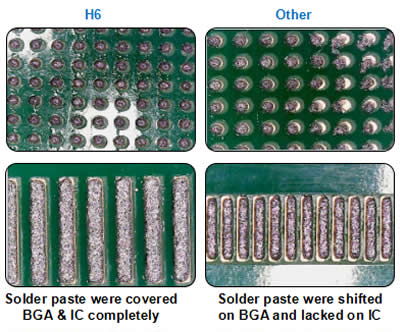

Printing Result Comparation | |

500X Microscope Inspection | |

| Conclusion: Printing result is perfect, no misalignment, shift, solder bridge, lack solder, etc. |

| Use same sample to test H4E and other brand to check IC and BGA. |

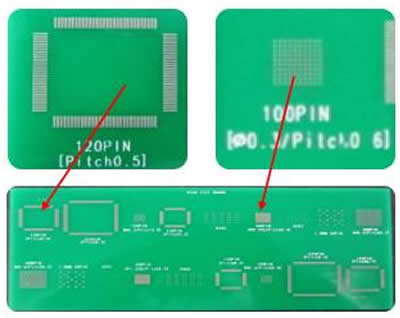

Printing Result Comparation (SPI) | |

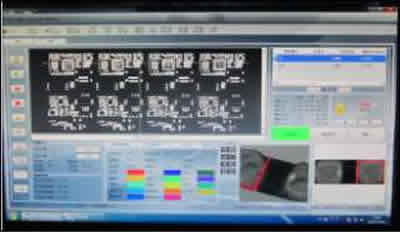

SPI inspection | |

| SPI inspection result: Production QTY: 192PCS |

| Conclusion: This PCB has many difficult IC and small pads, after inspection, result is good, machine can ensure printing quality and accuracy in production line. |

Fully Automatic Screen Printer H12 & H15 Features: |

● Arch bridge type suspending direct-connected scraper, programmable printing head. |

● Double sliders ensures the printing head moving accuracy and stability when scraper is running back and forth. |

● Programmable motor controls conveying speed and conveys PCB in the precise position. |

● The cleaning unit is separated from CCD camera, which can minimize the load of motor, improve the positioning precision and speed. |

● Automatic conveyor width adjustment. |

● Auto stencil cleaning(Dry/Wet/Vacuum). |

● Automatic 2D paste inspection. |

|

Fully Automatic Screen Printer H12 & H15 Specification: |

||||

|

Model |

H12 |

H15 |

||

|

Screen Frames |

Min Size | 737×300mm | 1100×300mm | |

| Max Size | 1500×750mm | 1800×750mm | ||

| Thickness | 25~40mm | 25~40mm | ||

|

PCB Min Size |

80×50mm |

80×50mm |

||

|

PCB Max Size |

Standard :1200×350mm | Standard :1500×450mm | ||

|

PCB Thickness |

0.8~6mm |

0.8~6mm |

||

|

PCB Warpage |

<1% | <1% | ||

|

Conveying Height |

900±20mm |

900±20mm |

||

|

Conveying Direction |

Left-Right; Right-Left; Left-Left; Right-Right | Left-Right; Right-Left; Left-Left; Right-Right | ||

|

Board Location |

Support System | Magnetic Pin/Up-down table adjusted/support block | Magnetic Pin/Up-down table adjusted/support block | |

| Clamping System | Side clamping, Automation retractable Z pressure | Side clamping, Automation retractable Z pressure | ||

|

Printer Head |

Two independent motorised printhead | Two independent motorised printhead | ||

|

Squeegee Speed |

6~200mm/sec | 6~200mm/sec | ||

|

Squeegee Pressure |

0~15kg |

0~15kg |

||

|

Squeegee Angel |

60° | 60° | ||

|

Squeegee Type |

Stainless steel(standard) |

Stainless steel(standard) |

||

|

Stencil Separation Speed |

0.1~20mm/sec (Programmable) | 0.1~20mm/sec (Programmable) | ||

|

Cleaning System |

Dry 、Wet 、 Vacuum (Programmable) | Dry 、Wet 、 Vacuum (Programmable) | ||

|

Table Adjustment Ranges |

X: ±10mm; Y: ±10mm; θ: ±2° | X: ±10mm; Y: ±10mm; θ: ±2° | ||

|

Solder Paste Inspection |

2D Inspection(Standard) |

2D Inspection(Standard) |

||

|

Repeate Position Accuracy |

±0.03mm | ±0.03mm | ||

|

Printing Accuracy |

±0.03mm |

±0.03mm |

||

|

Cycle Time |

<12s(Exclude Printing & Cleaning) | <12s(Exclude Printing & Cleaning) | ||

|

Product Changeover |

<5Min |

<5Min |

||

|

Air Required |

4.5~6kg/cm2 | 4.5~6kg/cm2 | ||

|

Power Input |

AC:220 ±10%, 50/60HZ, 3KW |

AC:220 ±10%, 50/60HZ, 3KW |

||

|

Control Method |

PC Control | PC Control | ||

|

Machine Dimensions |

2210(L)×1213(W)×1510(H)mm |

2510(L)×1353(W)×1510(H)mm |

||

|

Machine Weight |

Approx:1500kg | Approx:1800kg | ||

0 review for Donec eu furniture

Related Products

Thick Film Screen Printer Series

- Model: WZ-1202RS

Add a review

Your email address will not be published. Required fields are marked