- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

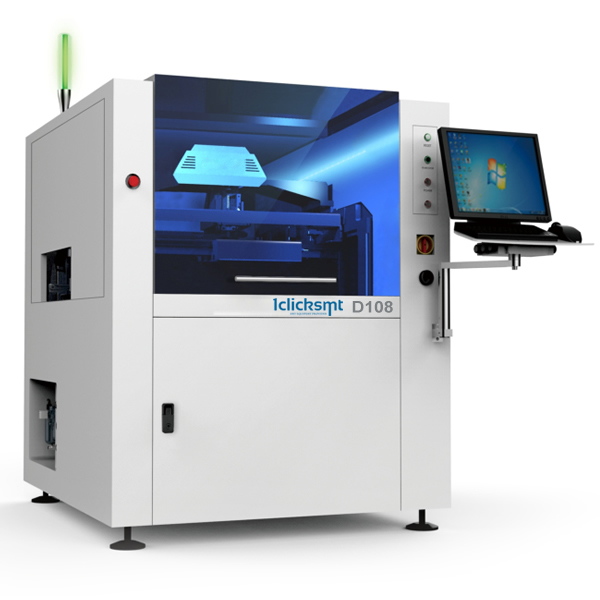

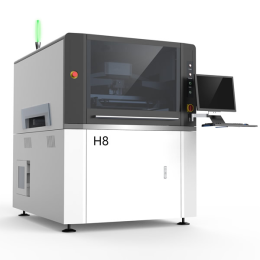

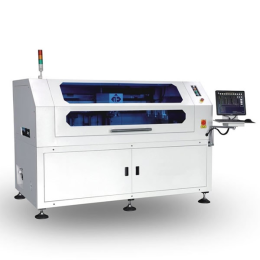

Automatic Screen Printer Machine D108

Classic reproduced, cost-effective model of first choice Product features: ▲Automatic visual alignment system; ▲Multi-functional image processing system; ▲Unique scraper self-adaptive system;

Available Options

Automatic Screen Printer Machine D108

×|

Automatic Screen Printer Machine D108 Product Options Configuration : |

|

|

|

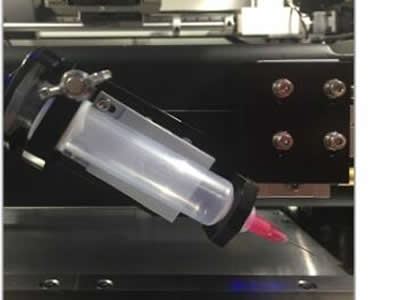

The rest of solder paste on the stencil monitoring system ● The solder paste inspection sensor before the scraper below remaining paste rolling diameter, intelligent prompt customers to join the solder paste. |

|

|

Automatic supply solder paste function ● General solder paste pot add directly ● Can be added at a fixed times ● can be real-time monitoring the roll diameter of the solder paste on screen, trigger automatically add functionality |

|

|

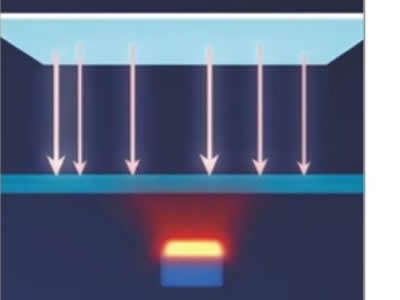

SPI close loop ● Form a closed loop system with SPI on line, when after receiving the SPI printing bad feedback,the machinewill automatically adjust automatically according to the offset of SPI feedback, x,y direction deviation can automatically adjust to complete, and automatic cleaning stencil, improve printing qualiy and production efficiecy, form a complete printing feedback system. |

|

UPS power off protection ● After power off a certain time(10minutes)PC can keep the power supply, the protection of prduction data |

|

|

|

Magnetic scraper ● The magnetic adsorption blade, replace the screw positioning, convenient and quick |

|

|

Stencil hole inspection ● Realization of plugging hole, hint whether clean steel net, steel net detect 2 consecutive failure,prompt the customer whether to replace cleaning mode, the frequency or manual cleaning. |

|

|

Intelligent temperature control system ● Temperature can be shown and adjustable on the overhead control system ● Temperature can be shown and adjustable on the external control system |

|

|

Industry 4.0 ● Production analysis and real-time statistical information function operation ● Alarm intelligent prompt system and processing solutions |

|

Bar code recogniton function ● Accept one dimensional code or two dimensional code on the customer's PCB board, record the relevant information. It can be shared with MES system and satisfied two types of scan ports. ● Fixed scan ● Hand-held scan ● Automatic scan (support for printing surface with bar code) |

|

|

|

Automatic dispensing function ● It can realize dot, area filling the pount |

|

Manufacturing Execution System ● Custom different communication modes of customers and realize intelligent opertion management |

|

|

Automatic Screen Printer Machine D108 Product size : |

|

|

|

Automatic Screen Printer Machine D108 Specification : |

|

|

Model |

D108 |

|

Process Parameters |

Specification |

|

Printing Accuracy |

>2Cpk@±25μm@,6☌ |

|

Repeat Position Accracy |

>2Cpk@±10μm@,6☌ |

|

Cycle Time |

7s |

|

Maximum Print Area |

400mm(X)×340mm(Y) |

|

Screen Frame Size |

470mm×370mm-737mm×737mm |

|

Screen Frame Thickness |

25mm-40mm |

|

Print Pressure |

0kg-10kg |

|

Ptint Speed |

1mm/sec-200mm/sec |

|

Print Gap |

0mm-20mm |

|

Substrate Separation |

Speed: 0.1mm/sec-20mm/sec |

| Distance:0mm-3mm | |

|

Separation option |

Separation after squeegee up; Squeegee up after separation |

|

Apply paste option |

Solder paste, printing ink,silver paste |

|

Transfer System |

Specification |

|

Belt Type |

U gear belt,front rail fixed |

|

ESD Compatibility |

Black transport belts and guides with surface resistivity of greater than 110Ω |

|

Width Adjustment |

Programmable motorized rear rail |

|

Transport Direction |

L→R,L→L,R→L,R→R |

|

Substrate Handling Size(Minimum) |

50mm(X)×50mm(Y) |

|

Substrate Handling Size(Maximum) |

400mm(X)×340mm(Y) |

|

Substrate Thickness |

0.4mm-5mm |

|

Substrate Weight(Maximum) |

≤ 3kg |

|

Substrate Warpage |

≤1% diagonal |

|

Substrate Fixture |

Flexible side clamp |

|

Substrate Underside Clearance |

≤18mm |

|

Vision |

Specification |

|

Multi function image process system |

Fiducial Mark software measurement,twice position, device identification function, Digital camera:1.3million pixels, the camera scene depth 2mm FOV:10*8mm |

|

Fiducial Recognition |

Automatic fiducial teach and find incorporating 0.1mm fiducial capture |

|

Fiducials |

Two or Four Fiducial marks Alignment System |

|

Fiducial Types |

□ spuare, ○ round, △ triangle, + cross, user-defined types |

|

Fiducial Size |

0.1mm-3mm |

|

Fiducial Locations |

Anywhere on substrate |

|

Fiducial Error Recovery |

Auto lighting adjustment |

| Auto fiducial search | |

|

Camera Lighting |

Manual adjustment |

|

2D inspect system |

2D detect soldr printing quality |

|

Electrical configuration and environmental requirements |

Specification |

|

Voltage |

220Volts+/-10%. Single phase 50/60Hz |

|

Power |

3kw |

|

Air Supply |

0.45-0.6kg/cm² |

|

Temperature |

25±3℃ |

|

Humidity |

30%-70% relative humidity (non condensing) |

|

Standatd Configuration |

Specification |

|

Printer Construction |

One piece optimized welded frame |

|

Machine Control |

Three control motion control card |

|

Operation System |

Windows XP , Win7(option) |

|

Operator Interface |

17" DELL display screen, keyboard and mouse and DESEN V2 software,display on the right hand side. |

|

Squeegee |

Direct screw/single-point suspension squeegee |

|

Constant intelligent control syetem of squeegee pressure |

Pressure adjusted by software control |

|

Autmatic positioning module of stencil |

Put the stencil into support frame, the squeegee automatically realizes the positioning of the stencil |

|

Support positioning system |

Support block, support pin, support platform |

|

Intelligent cleaning system |

The diffrent size of wipe paper can be used, less paper consumption, solvent agent control module |

|

Stencil Alignment |

Program control, Y direction orientated |

|

Machine Iterface |

SEMI Input/Output 4 core internatiol standard interface |

|

Connectivity |

RJ-45LAN(networking)and USB2 interface available |

|

Three color intelligent LED warning light |

Programmable with audible alarm |

|

High performance high precision platform |

The platform processing method adopts the annealing process and the knife quick milling method,and the residual of the metal stress in the platform is reduced. Easy deformation,precision assurance. |

|

Fast platform adjustment system |

Knob type manual rapid adjustment platform height |

|

Intelligent compensation platform |

X,Y,θ multi axis independent adjustment |

|

Intelligent transmission system |

The automatic limit device + automatic positioning substrate +left into the left, the left into right,right into the right, right into the left out |

|

Documentation |

Hard coopy manuals comprising:Opeartor, Installation,and Electrical Drawings. On board technical manuals and tutorals supporting operator functions. |

|

Approximate Dimensions |

1140(L)×1360(W)×1505(H)mm |

|

Approximate Weight |

1300kg boxed (dependent upon configured options selected wiht machine) |

| 1100kg unboxed (dependent upon configured options selected wiht machine) | |

|

Software & Communications |

Specification |

|

Software intelligent backup module |

Database automatic backup software upgrade is not lost |

|

Maintenance early warning function |

Machine wire rod, slide block, motor and other automatic maintenance message |

|

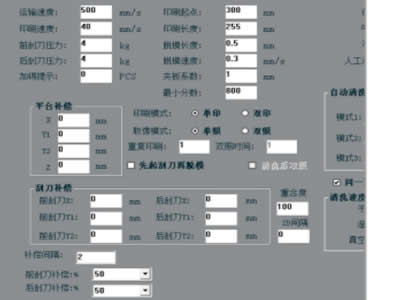

Printing parameter intelligent module |

Customer select the type of production, like FPC,LED, Phone PCB...the printer can give the parameter automatically. |

|

Recovery system of solder paste |

The fixed frequency to recovery the solder paste into the printing area. |

|

Certification |

Specification |

|

CE |

98/37/EC, 89-336/EEC, 73/23/EEC |

|

Acoustic Noise Level |

Less than 70dB |

3 review for Donec eu furniture

wspnet - 2021-11-20 09:49:33

adsafasdfasdfasd434343 - 2021-12-28 02:23:34

34344334Add a review

Your email address will not be published. Required fields are marked

Related Products

Fully Automatic Screen Printer H12 & H15

- Model: H12 & H15

Thick Film Screen Printer Series

- Model: WZ-1202RS

sdfd - 2021-11-20 09:47:08

dsfads