- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

X-Ray machine SoYi-R9

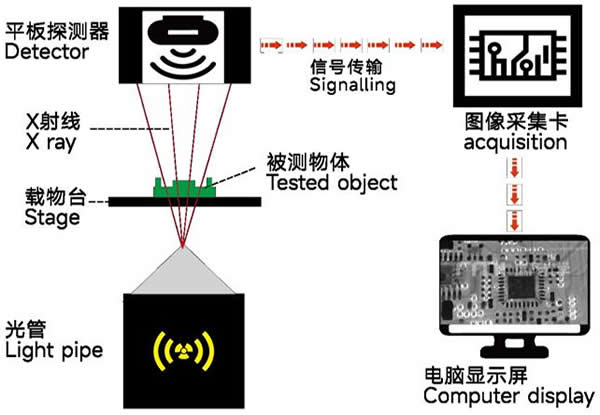

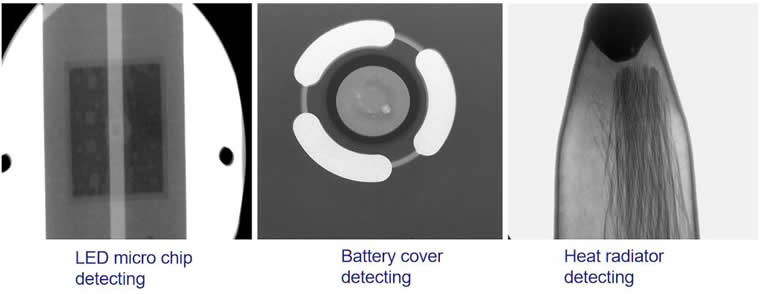

The system mainly consits of micro focal X-ray source, image imaging unit, computer image processing system, mechanical system, electrical control system, safety protection system, warning system, including modern non-destructive tessolderg, computer software technology, image acquisition and processing technology, mechanical transmission technology as a whole, covering the optical, mechanical, electrical and digital image processing four categories of technology fields. X-ray absorption differences by different materials, the internal structure of objects imaging and detection of internal defects, can be real-time observed products inspection image, determine whether the internal defects and defect types and grades, at the same time through the computer image processing system to complete the image storage and processing, in order to improve the image resolution, Ensure the accuracy of the assessment. SoYi-R9 can achieve inspeciton accuracy of 1um, can be used to detect integrated circuit chip semiconductor, such as BGA, IGBT, inverted chip and PCBA component welding, LED state, IC packaging and other industries of high precision testing.

Available Options

X-Ray machine SoYi-R9

×

|

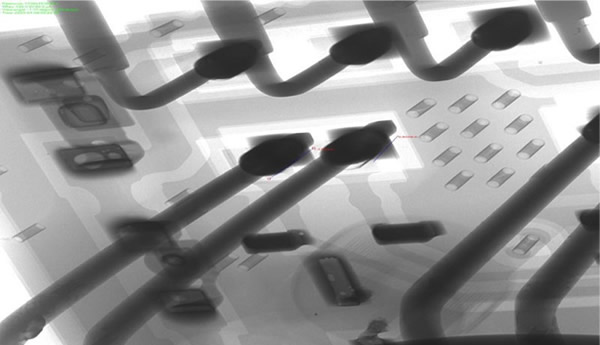

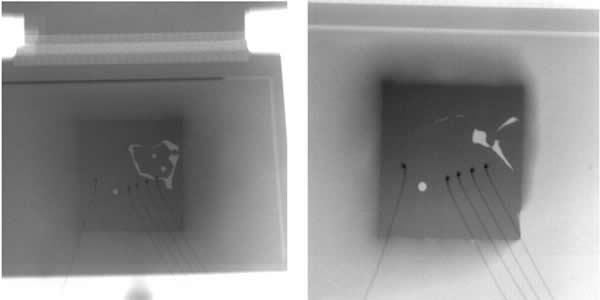

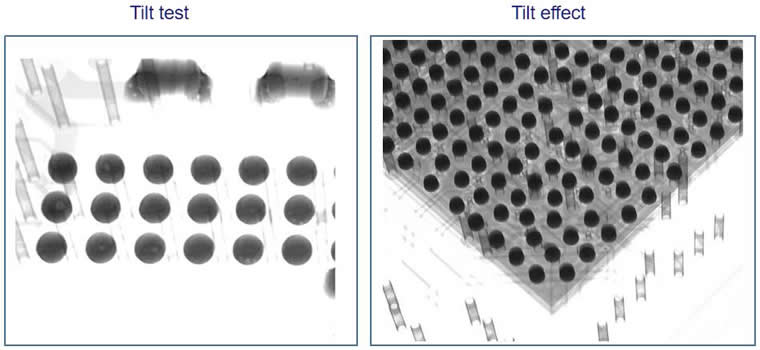

X-Ray detecting theory ● X-Ray tube and flat panel detector can tilt 60 degree for inspection. |

|

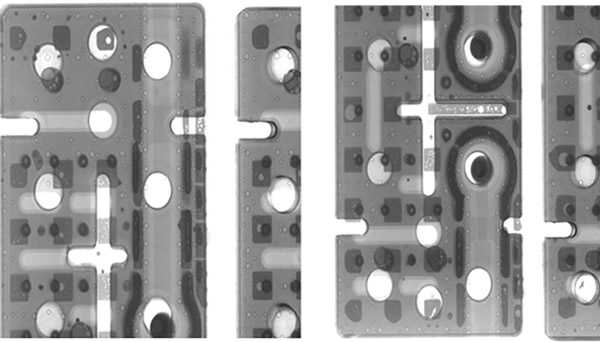

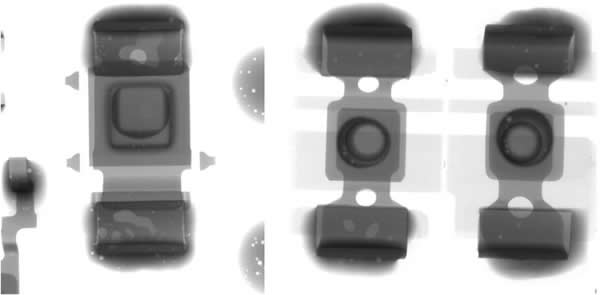

Common defect-Electronic semiconductor |

|

|

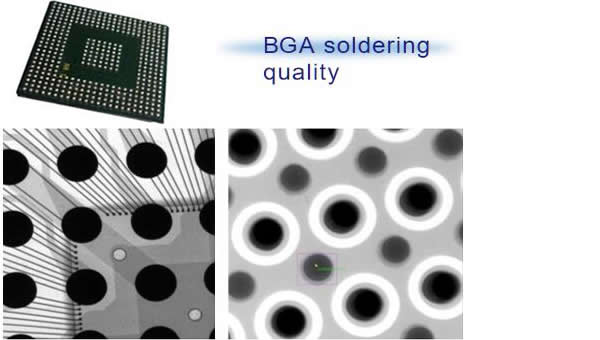

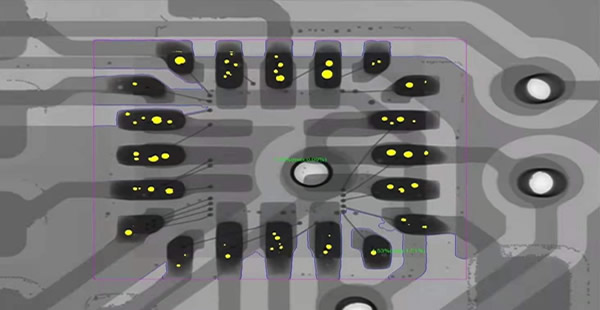

BGA soldering quality |

|

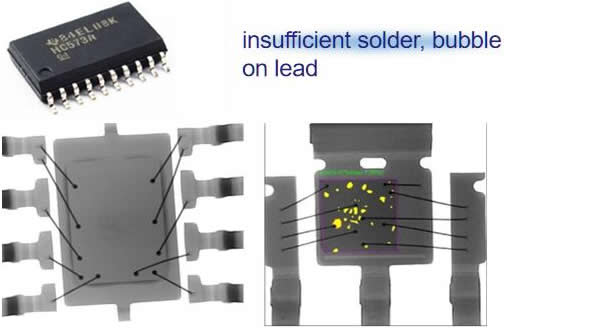

insufficient solder, bubble on lead |

|

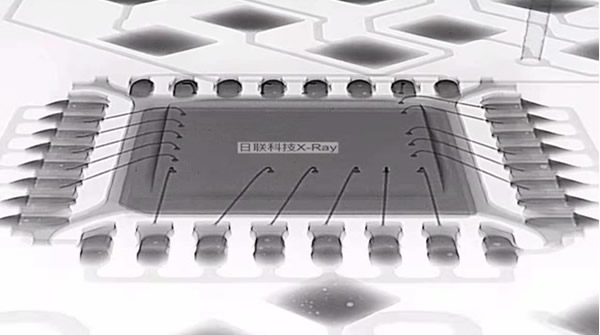

IC golden wire \ bubble detecting |

|

Solder height |

|

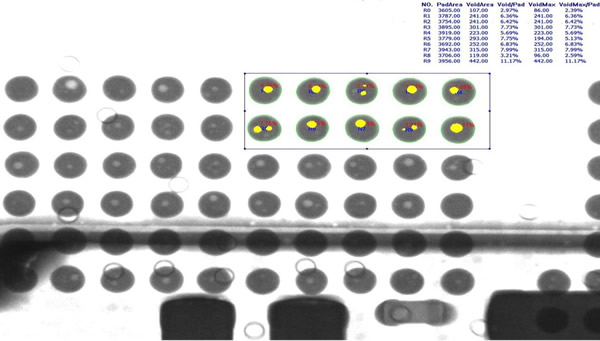

Soldering point bubble measuring |

|

BGA bubble measuring |

|

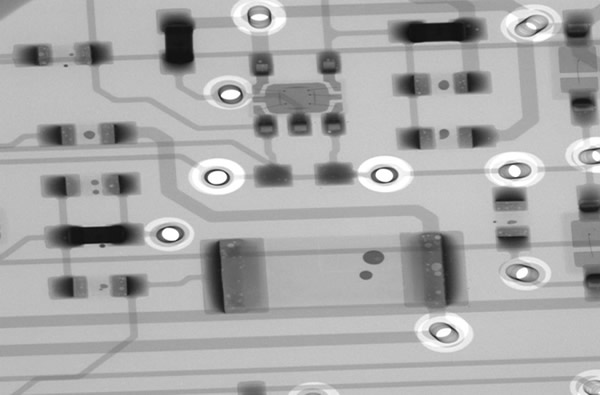

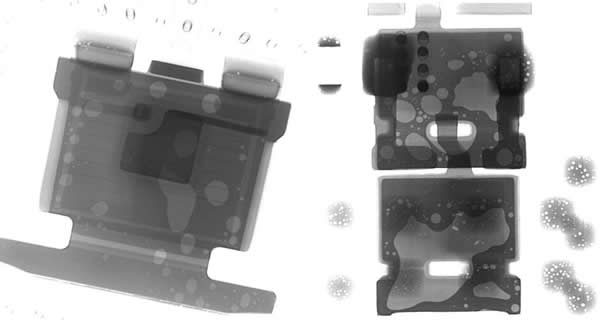

PCBA detecting |

|

5G Base station circuit board detecting |

|

LED bubble detecting |

|

Chip bubble detecting |

|

Chip bubble detecting |

|

|

|

|

|

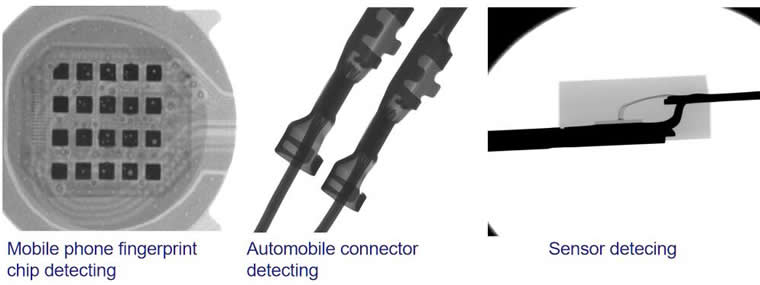

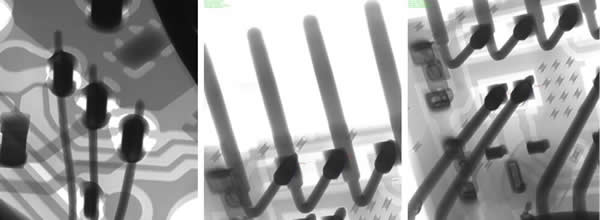

DIP soldering height detecting |

|

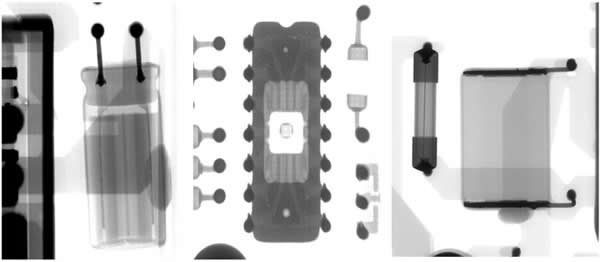

Component detecting |

|

|

|

SoYi-R9 X-RAY machine Advantage |

|

1, CNC programming, automatically inspect multiple position. |

|

2, Automatically inspect multiple components on same position. |

|

3, High end X-ray source with flat panel makes inspection accuracy can reach 1um. |

|

4, One key to measure void size and percentage. |

|

5, X-Y movement controlled by joystick. |

|

6, X-Ray source can tilt 60 degree to inspect components. |

|

7, Big loading platform, easy to inspect big product. |

|

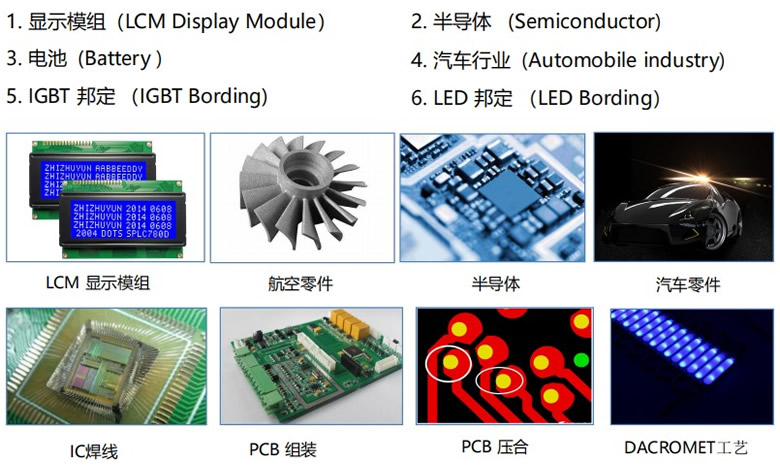

8, Wide application shown as right picture. |

|

|

SoYi-R9 Specification | |||

| Hardware | X-Ray Source | Type | Enclosed |

| Volatge | 100kV(200uA) | ||

| Brand | CANON, made in Japan | ||

| Spatial resolution | 1um | ||

| Imaging unit | Type | Flat panel detector | |

| Tilt angle | Single side 60° | ||

| Pixel matrix | 1648*1644 pixel | ||

| Pixel size | 76um | ||

| Frame rate | 30ps | ||

| System magnification | 450X | ||

| Brand | DRTECH | ||

Computer | Industrial PC | Industrial PC, Window 10 system | |

| Display | 23” | ||

Loading platform | Loading area | 690mm×685mm | |

| Detecting area (max) | 670mm×665mm | ||

Software | Software | Self-developed image processing system | |

| Auto measuring | BGA soldering voids auto measuring, support data /graphic output | ||

| Multi measuring tools | Support measuring distance, angle, diameter, polygon, PTH filling rate, etc | ||

| Real time display | Real time diplaying the working data of voltage, current, angle, date, etc. | ||

| CNC programming | CNC programming to detect mutiple position autimatically | ||

Gerneral | Power | 2kW | |

| Size | 1510*1770*1850mm(L*W*H), not including display and lighting tower | ||

| Weight | 1800KG | ||

Add a review

Your email address will not be published. Required fields are marked