- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

DA-1200 THT Component Automated Inspection System

DA-1200 is a new kind of automtaic AOI equipment for THT component with high cost performance, which can be easily installed on the existing production line. It can automatically inspect defects of THT compoments instead of the traditional manual inspection. DA-1200 uses intelligent algorithm which can train the components with large sample images to comprehensively recognize the features of the components to improve the misjudge problems, and make programming very easy.

Available Options

DA-1200 THT Component Automated Inspection System

×|

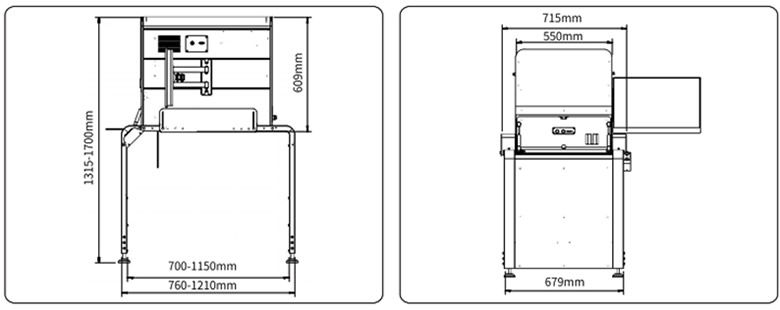

DA-1200 THT Component Automated Inspection System Dimension: |

||

|

Dimension of the machine: The equipment can be easily installed on the production line without any modification of production line. |

||

|

||

|

THT Component Automated Inspection System Software: |

||

|

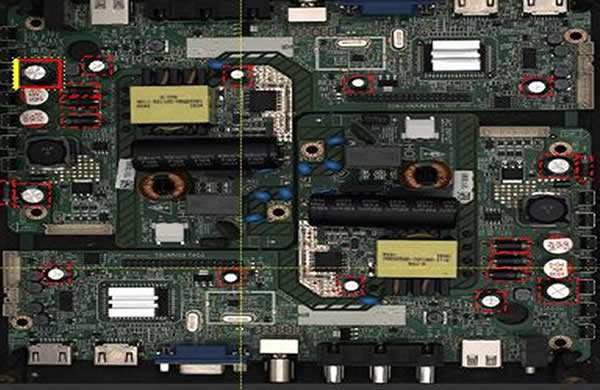

Detection items: Wrong, Miss, Reversed, Skew, Redundant of THT components. Rapid detection: Machine is installed above existing conveyor, automatically inspect PCBA without stopping PCBA, production efficiency: > 450pcs /hour |

||

|

||

|

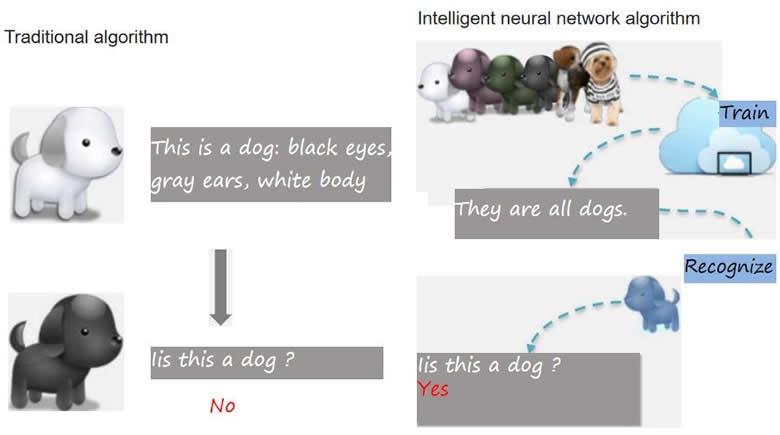

THT Component Automated Inspection System Algorithm: |

||

|

Intelligent algorithm: Intelligent neural network algorithm which can train the components with large sample images to comprehensively recognize the features of the components to improve the misjudge problems, and make programming easy. |

||

|

Priciple comparision with raditional algorithm |

||

|

||

|

|

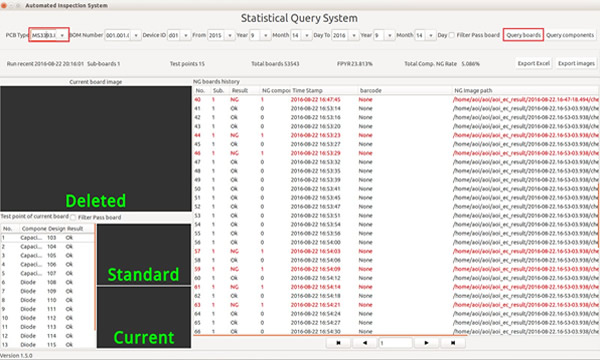

Simple programming: click the automatic search button, and the software will automatically identify the standard components such as capacitance, diode. Support online debugging and update the program, support offline programming. |

|

|

|

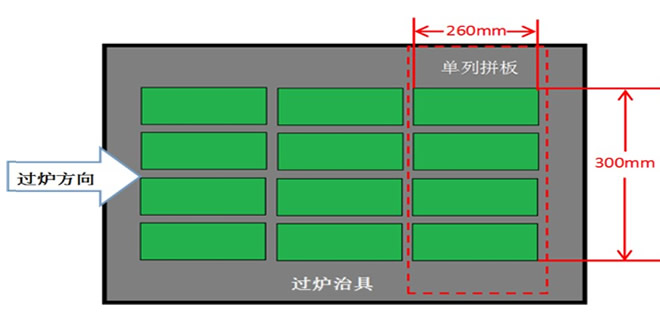

Support panel board programming. Multi boards can be inspected at same time. |

|

|

|

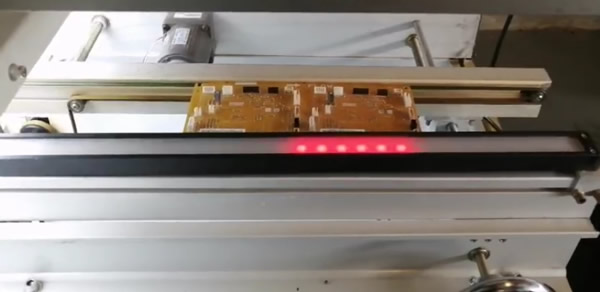

NG Tracking LED Bar (LED light following NG product to help confirming NG product). |

|

|

|

Powerful data statistic software, easy to search and to be exported as a exel file. |

|

|

DA-1200 THT Component Automated Inspection System Features: |

|

● Simple installation: The equipment can be easily installed on the production line without any modification of production line. |

|

● Detection items: Wrong, Miss, Reversed, Skew, Redundant of THT components. |

|

● Ease programming: one-key programming for standart component, support offline programming, support online degugging without stopping production. Quickly operate the equipment after 2 hours training, Quickly change production line and make new program within 10 minutes. |

|

● Rapid detection: Machine is installed above existing conveyor, automatically inspect PCBA without stopping PCBA. |

|

● Intelligent algorithm: Intelligent neural network algorithm which can train the components with large sample images to comprehensively recognize the features of the components to improve the misjudge problems, and make programming easy. |

|

● Testing of multiple boards at same time: Multiple boards can be tested at same time, and various kinds of board layouts can be considered. |

|

● Data statistics software: standart data statistics software, easy to search and export detailed statistical data. |

|

● Capable to connect with MES(option). |

|

DA-1200 THT Component Automated Inspection System Specifications |

|||

| Model | DA-1200 | DA-2900 | |

| Optics Specification | Testing method | Deep neural networks based methods, contrast based methods, col based methods | Deep neural networks based methods, contrast based methods, col based methods |

|

Camera |

12 million pixel, Color CCD | 31MP, Color CCD | |

|

Light source |

Flat white LED Light |

Flat white LED Light |

|

| Testing Specifacation |

Items of testing |

Wrong, Miss, Reversed, Skew, Redundant | Wrong, Miss, Reversed, Skew, Redundant |

|

Min component size |

3*3mm |

3*3mm |

|

|

Detectable PCB size |

Max: 400*300mm | Max: 520*380mm | |

| Computer specifications |

Operation System |

Ubuntu 18.04 LTS 64bit |

Ubuntu 18.04 LTS 64bit |

|

Industrial control computer |

CPU: intel i5 Display card: NVIDIA GTX1050Ti Memory: 8G DDR, 256G SSD+2T Mechanical Hard Disk Network: 1000M Wired Network Card |

CPU: intel i7 Display card: NVIDIA GTX1050Ti Memory: 8G DDR, 256G SSD+2T Mechanical Hard Disk Network: 1000M Wired Network Card |

|

|

Displayer |

22 inch |

23.8 inch |

|

| Equipment Specification |

Size |

W 640*D(760~1210)*H(1315~1700)mm(Desktop type without conveyor) | |

|

Weight |

100kg |

100kg |

|

|

Power supply |

1P, AC220V 50HZ | 1P, AC220V 50HZ | |

|

Power |

230W |

230W |

|

|

Operating temperature |

5~45℃ | 5~45℃ | |

| THT Component Automated Inspection System Application |

|

|

DA-1200 THT Component Automated Inspection System Includes: |

|

Standard configuration: |

|

1. DA-1200 THT Component Automated Inspection System. |

|

2.Online programming software (combined with AOI software). |

|

3.Data statistic software (combined with AOI software). |

|

|

|

Option configuration : |

|

1. Offline programming software. |

|

2. NG Tracking LED Bar (LED light following NG product to help confirming NG product). |

0 review for Donec eu furniture

Related Products

Benchtop Repair Station BRS-100

- Model: BRS-100

Add a review

Your email address will not be published. Required fields are marked