- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

Unit-i4 inline 4 nozzle compact selective soldering

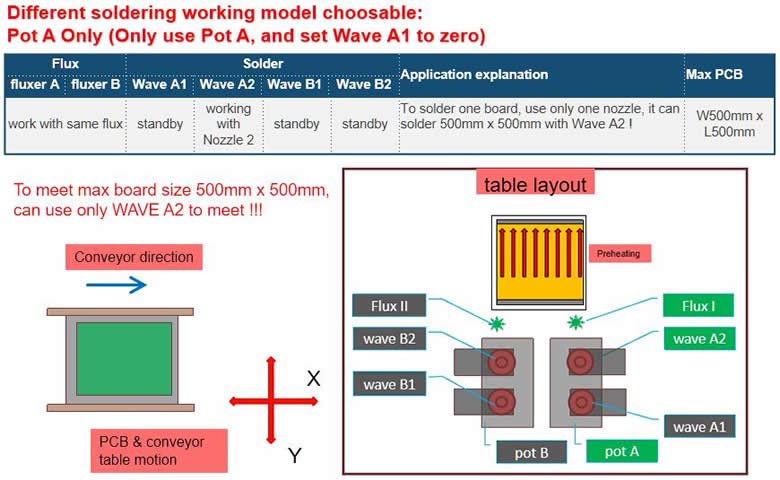

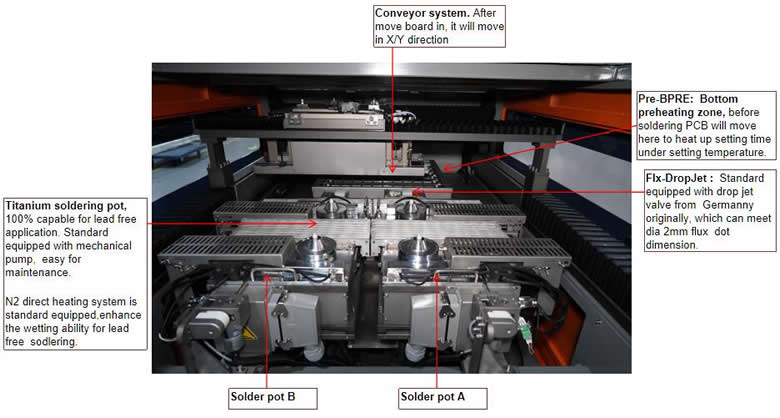

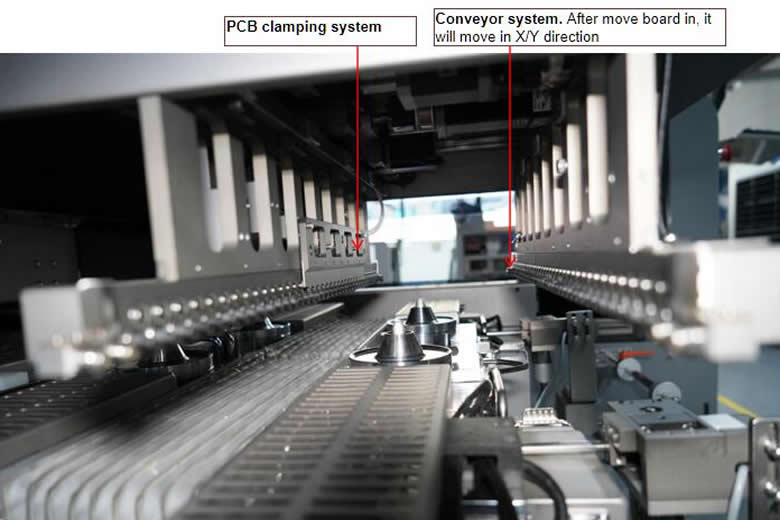

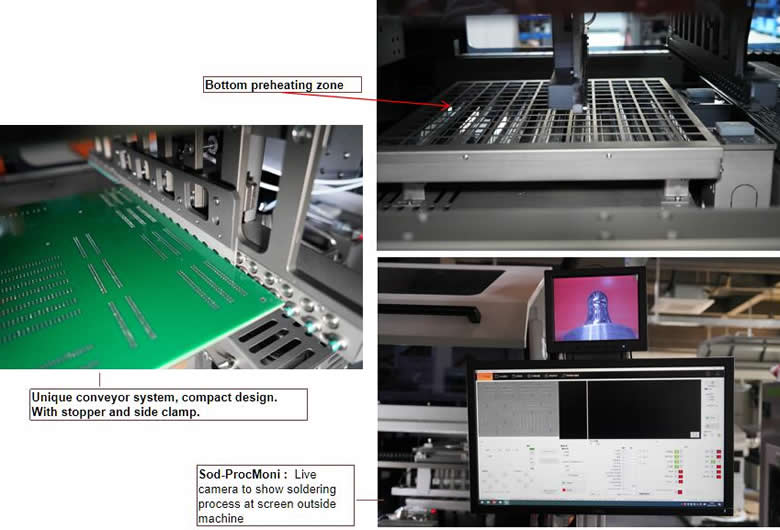

Unit-i4 is the latest generation selective with below feature: Highest output, Highest ROI, Highest flexibility, Compact inline !!! ● Two drop jet fluxer nozzle. And work together to apply flux for two board, also can use different type of flux or flux nozzle. ● Inbuilt with bottom IR preheating zone. ● Conveyor table is moving in X/Y direction under server motor. During soldering, it will combine solder pot’s Z direction motion to finish soldering with XYZ direction motion. ● Two individual solder tank, can use one for lead-free and another with leaded. Or same solder in two tank for max production for 4 board paralley soldering. ● Standard equipped with wave height calibration. ● Windows 10 system English version.

Available Options

Unit-i4 inline 4 nozzle compact selective soldering

×|

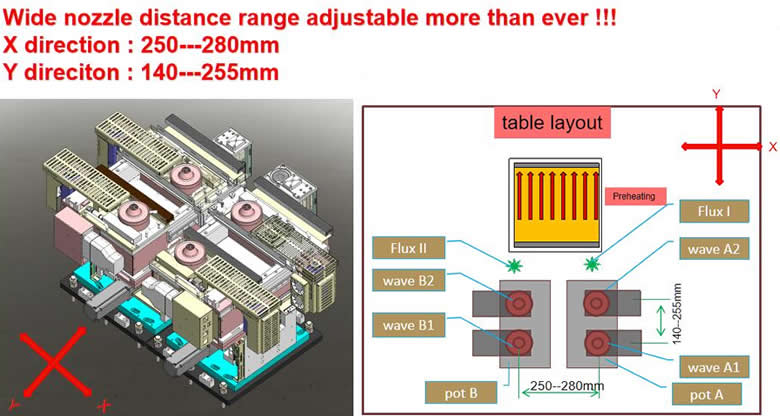

General Explanation: Solder nozzle distance range |

|

|

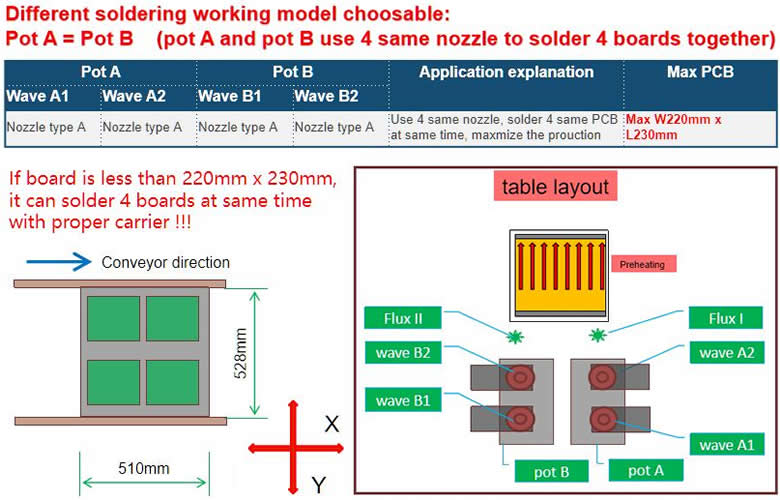

General Explanation: How to meet “Highest output, highest ROI” |

|

|

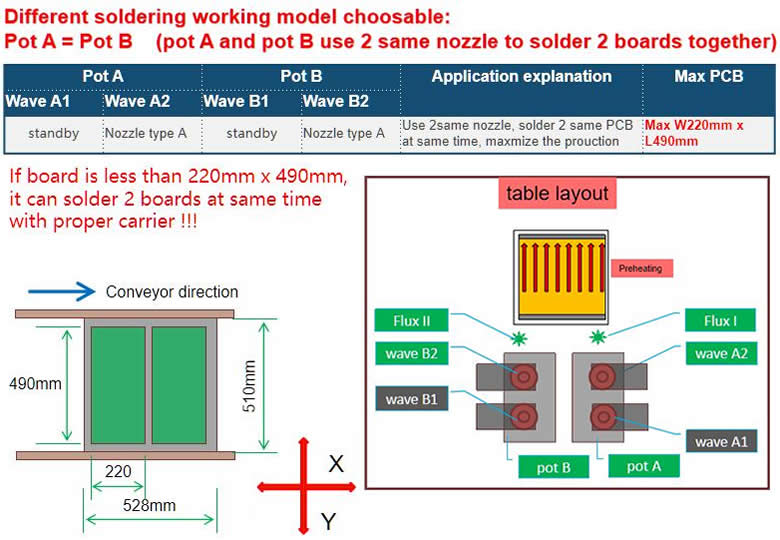

General Explanation: How to meet “Highest output, highest ROI” |

|

|

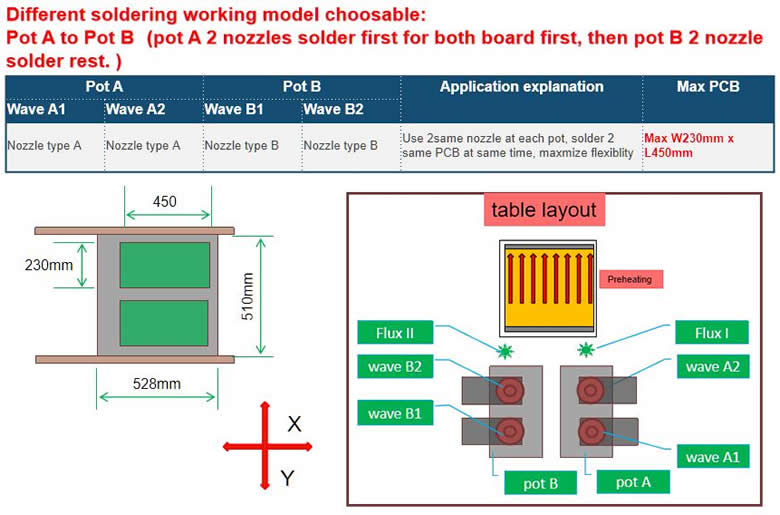

General Explanation: How to meet “Highest output with high flexibility” |

|

|

General Explanation: How to meet “Highest output with high flexibility” |

|

|

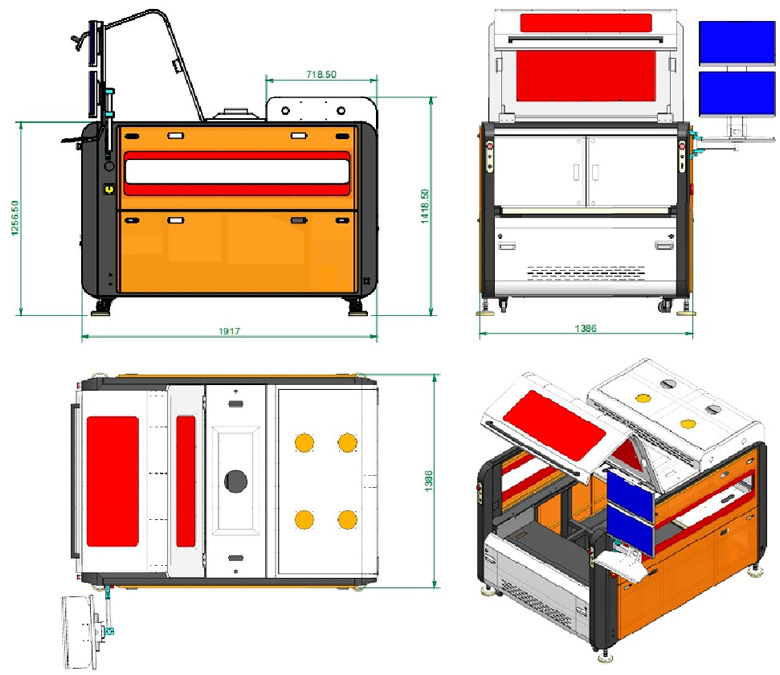

Compact inline Selective Soldering Machine |

|

|

Compact inline Selective Soldering Machine |

|

|

Compact inline Selective Soldering Machine |

|

|

Compact inline Selective Soldering Machine |

|

Unit-i4 Specifications | |

Item | Unit-i4 |

General |

|

Operating power/Max power | 6KW/22KW |

PCB dimension | 50x50---W508xL508mm (using one nozzle only) |

| 50x50---W220xL450mm (using only 2 nozzles together) | |

| 50x50---W220xL230mm (using all 4 nozzles together) | |

PCB top clearance PCB | 70mm |

PCB bottom clearance PCB | 30mm |

Max PCB & carrier load | 3kgs |

Machine dimension | 1386(W)*1917(D)*1418(H) |

Net weight | 700KG |

Power supply | 3PH 380V 50HZ |

Air supply | 3-5 bars |

Exhausting required | 500M3/h |

Controlling System |

|

Industrial PC | Yes |

Typical Program Time | 10 Minutes |

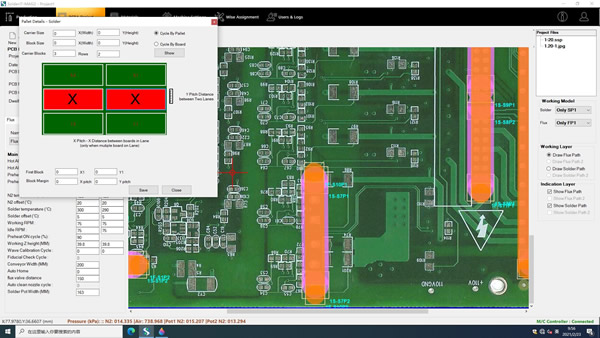

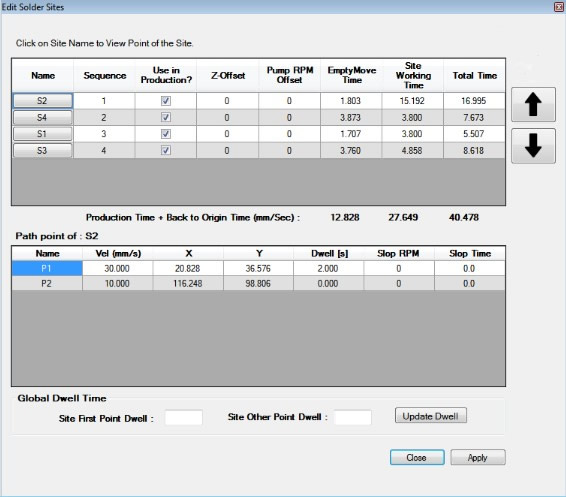

Program method | Draw path in scanned picture of board |

Controlling system | PC |

PCB Robotic Platform |

|

Axes of Motion | X, Y, Z |

Motion Control | Servo motors for X,Y,Z |

Position Accuracy | + / - 0.05mm |

Fluxing system |

|

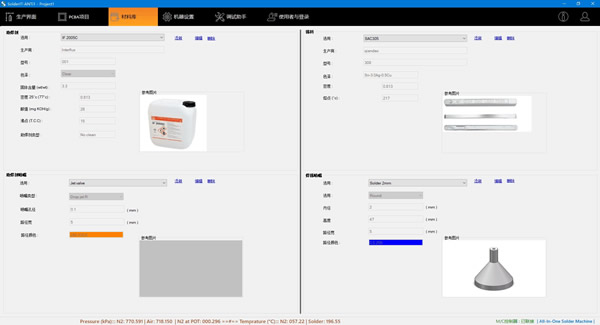

Flux Nozzle Type | drop jet nozzle made in Germany |

Flux nozzle number | 2 sets |

Flux Capacity | 1L x 2sets |

Flux Tank | Constant pressure tank |

Cleaning tank | Constant pressure tank |

Cleaning Capacity | 1L x 1set |

Preheat |

|

Bottom preheating | 4kw (bottom) |

Soldering system |

|

Solder Pot quantity | 2 |

Solder Pot Capacity | 35kgs / pot x 2pots |

Wave tunnel & fountain | 2 sets / pot x 2pots = 4 sets |

Wave nozzle number | 2 nozzle /pot x 2pots |

Wave nozzle distance adjustment | See layout |

Pump type | Mechanical pump |

Solder Temperature Control | PID |

Heat-Up Time | About 40mins |

Max Temperature | 380 ℃ |

Solder Pot heater | 2.4kw/pot x 2 pots |

Solder Nozzles |

|

Mini Wave Nozzles | Dia 4, 6,8,10,12mm |

Customized nozzle | Available |

Nozzle Material | Proprietary Alloy |

(N2) Inertion Management |

|

N2 heater | Standard Equipped, individual for each solder nozzle |

N2 Temp PID Control Range | 25 - 250 ℃ |

N2 Consumption per Nozzle | 1.5m3/H Total need: 6m3/H (Recommend to connect with Selmate-8 N2 generator) |

Required N2 Purity | >99.99% |

Conveyor System |

|

Conveyor height | 900+/-30mm |

Conveyor type | mini shafts |

Conveyor width adjustment | Auto by software |

Conveyor stopper | yes |

Conveyor side clamp | yes |

SMEMA connection | yes |

Alarm & monitoring |

|

Air pressue monitoring | yes |

flux level alarm | yes |

cleaning solvent level alarm | yes |

N2 flow monitoring | optional |

N2 purity monitoring | optional |

Solder process monitoring | yes |

solder level alarm | yes |

temperature alarm | yes |

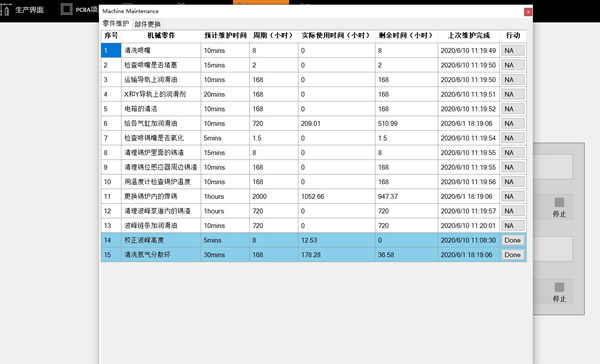

maintenance remind | yes |

consumable parts life time count down | yes |

Motion table limit alarm | yes |

|

Software System |

|

|

|

Solder It ● “Solder It” is a Windows Professional 10 based software designed to create a solder program. It can easy POINT AND CLICK for fluxing path and soldering parameters. |

|

|

● All motion path can be editable, include soldering speed, empty move speed, dwell time, solder Z height, wave height, wave slop speed, solder leaving angle, N2 temperature etc. Meanwhile, any factors related to good soldering result, it will be monitored, for sample all air pressure, N2 pressure, N2 purity, N2 flow rate etc. |

|

|

● Date base information. Engineer can input all solder, flux, solder nozzle information to machine. When doing programming, they can add these information to programming of board. In future to produce the same board, it will be easy to get not only motion information, but also what flux/solder/nozzle was used before, easy to repeat soldering quality. |

|

|

● Pre-maintenance & consumable parts timing function. Can count down consumable parts’ life time, remind engineer to do necessary change in advance. Also, can remind for necessary maintenance of machine. |

|

|

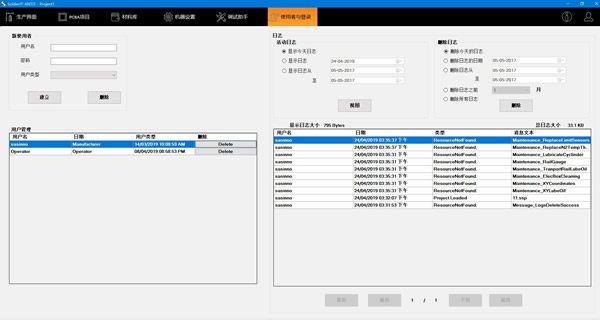

● 3 Level logging rights and date log information records. Who use machine, when use machine, what unnormal happen on machine, all these will be recorded. |

0 review for Donec eu furniture

Related Products

Flex-i2 Inline Selective Soldering Machine

- Model: Flex-i2

Ant-i2 Offline Selective Soldering Machine

- Model: Ant-i2

MAS-i2 Inline Selective Soldering Machine

- Model: MAS-i2

MAS-i4 Dual pot selective machine

- Model: MAS-i4

Unit-i1 inline 1 nozzle compact selective soldering

- Model: Unit-i1

Add a review

Your email address will not be published. Required fields are marked