- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

Vertical Cleaner for Stencil & PCBA VSP-870

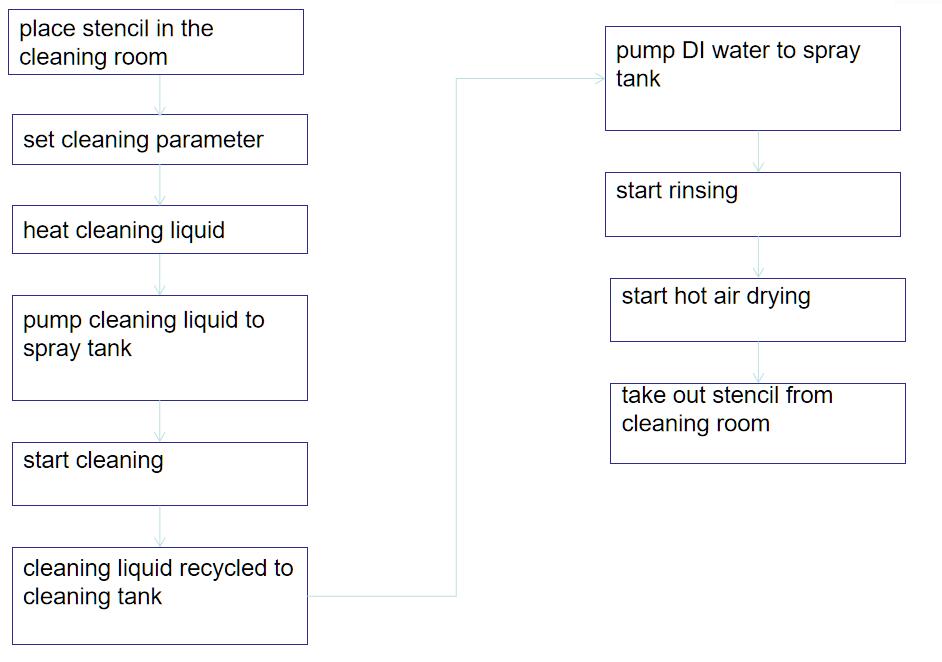

VSP-870 use water based liquid for screen stencil ,PCBA, printing scraper cleaning. The equipment can realize atutomatic cleaning ,rinsing and drying process accroding to preset program.

Available Options

Vertical Cleaner for Stencil & PCBA VSP-870

×|

The whole machine is made of 304 stainless steel, beautiful and durable.

|

|

|

|

● Visual viewing window to monitor cleaning process, pressure guage to monitor system working pressure in real time. |

|

|

● 0.22um precision Filtering System ensure cleaning quality |

|

|

● DI water conductivity mointor to monitor resistivity of rinsing DI water in real time |

|

|

● Hot air drying system. |

|

Vertical Cleaner for Stencil & PCBA VSP-870 Features: |

| ● Double liquid tank with heating, hot air drying, realize atutomatic cleaning, rinsing and drying process accroding to preset program. Cleaning process: High pressure liquid jet cleaning -chemical insolation- DI water rinsing - hot air drying. |

|

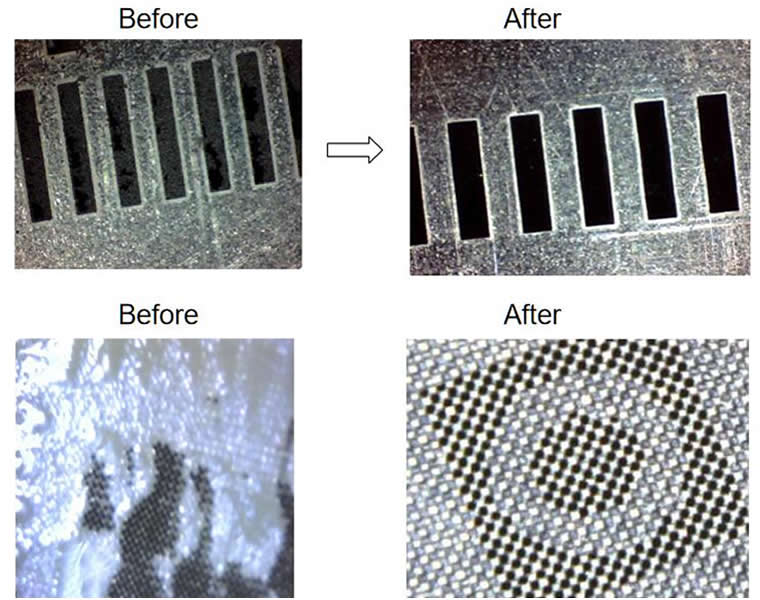

● The equippment use water based liquid with high pressure jet for screen stencil ,PCBA, printing scraper cleaning. production. |

|

● The most scientific nozzle design:Increasing nozzles from left to right, Enhance the cleaning efficiency, Distribution nozzles up and down, Completely solve the blind clean area. |

|

● Large cleaning size:800mm(L) ×750mm(W) × 40mm(H), special product size can be customized. |

|

● Quick installed nozzle is easy for maintenance. |

|

● Cleaning pressure is adjsutable to meet different cleaning requirement. |

|

● Monitor resistivity of rinsing DI water in real time to ensure cleaning quality. |

|

● Mointor filter lifetime in real time and remind operator to replace filter. |

|

● Automatically count cleaning time. |

|

● PLC + touchscreen control, full english interface, easy to operate. |

| ● Motor overload protection, overheating protection to prevent machine damaged. |

|

Vertical Cleaner for Stencil & PCBA VSP-870 specification : |

|

|

Model |

VSP-870 |

|

Max Product Size |

Max 800mm(L) ×750mm(W) × 40mm(H) |

|

Cleaning Tank Capacity |

Max 50L |

|

Cleaning method |

High pressure jet liquid for cleaning |

|

Drying method |

hot air for drying |

|

Cleaning liquid filtering |

0.22 um filter |

|

Cleaning Time |

Reference cleaning time: solder paster 8-10 minutes, red glue 15 minutes, misprinted board 15 minutes. |

|

Dilution Liquid Heating Temperature |

RT+15~70℃ |

|

Resistivity Meter Monitoring Range |

1mΩ~18mΩ.cm |

|

DI Water Supply |

15~50L/min |

|

DI Water Pressure |

0.2-0.4Mpa |

|

DI Water Entrance Pipe Connection |

1 inch |

|

Power Supply |

3Phase 380V 50/60HZ |

|

Net Weight |

Approx 500Kg |

|

Exhaust Size |

Φ124mm(W)×30mm(H) |

|

Machine Size |

1650mm(L) ×1160mm(W) ×1910mm(H) |

|

Exhaust flowrate requirement |

20M3/Min |

|

Cleaning liquid consumption |

20ml--300ml/batch, varies according to products. |

|

DI water consumption |

40L/rinsing for 3 times |

|

Vertical Cleaner for Stencil & PCBA VSP-870 Configuration : |

|

● Vertical Cleaner for Stencil & PCBA VSP-870*1 set |

|

● 0.22μm filter core *2pcs |

| Vertical Cleaner for Stencil & PCBA VSP-870 Application : |

|

0 review for Donec eu furniture

Related Products

Pallet Cleaner AQ-601

- Model: AQ-601

ZQ-6800I Inline PCBA Cleaning Machine

- Model: ZQ-6800I

Pneumatic Scraper And Misprinted PCBA Cleaner PSC-600

- Model: PSC-600

Offline PCBA Cleaner AQ-650

- Model: AQ-650

Add a review

Your email address will not be published. Required fields are marked