- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

Microfocus X-Ray Counter MXC430

1. America closed type X-ray tube, long lifetime, maintenance-free. 2. 17” super definition digital flat panel detector (FPD), eliminate the scanning detector. 3. Ultrafast counting, one 7” (180mm) reel needs about 9s, four 7” reels or one 15” (380mm) reel needs about 14s. 4. Can count max 17” (430mm) diameter reel with a moisture barrier bag or JEDEC tray, etc. 5. Artificial intelligence deep learning algorithm with independent intellectual property rights, software accumulates data to the cloud database and shares it to all machines. 6. No need to enter the reel data in the factory in advance, users can use it directly. 7. Compared with the traditional parts counter, it can greatly improve the efficiency and accuracy, save manpower, and greatly shorten the time of material entering and leaving the warehouse. 8. Support MES, ERP, and other systems, to manage material warehouses digitally. Permanent software algorithm updates.

Available Options

Microfocus X-Ray Counter MXC430

×|

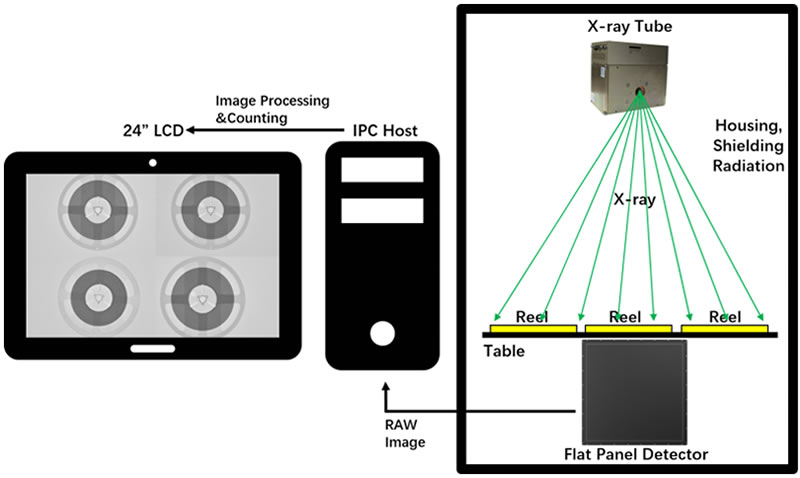

Working Principle |

|

|

|

Our Advantages Features |

|

● America closed type X-ray tube, long lifetime, maintenance-free. |

|

● 17” super definition digital flat panel detector (FPD), eliminate the scanning detector. |

|

● Ultrafast counting, one 7” (180mm) reel needs about 9s, four 7” reels or one 15” (380mm) reel needs about 14s. |

|

● Can count max 17” (430mm) diameter reel with a moisture barrier bag or JEDEC tray, etc. |

|

● Artificial intelligence deep learning algorithm with independent intellectual property rights, software accumulates data to the cloud database and shares it to all machines. |

|

● No need to enter the reel data in the factory in advance, users can use it directly. |

|

● Compared with the traditional parts counter, it can greatly improve the efficiency and accuracy, save manpower, and greatly shorten the time of material entering and leaving the warehouse. |

|

● Support MES, ERP, and other systems, to manage material warehouses digitally. Permanent software algorithm updates. |

|

Microfocus X-Ray Counter MXC430 Specification: |

||

|

Model |

MXC430 |

|

|

X-ray source |

Type | Closed, microfocus |

| Max tube voltage | 80kV | |

| Max tube current | 700μA | |

| Focal spot size | 30μm | |

|

Flat panel detector |

Type | Super definition digital FPD |

| Effective area | 427mm*427mm | |

| Pixel size | 139μm | |

| Resolution | 3072*3072 | |

|

Reel/tray counting |

Max size | 17” (430mm) |

| Max thickness | 85mm | |

| Min parts size | 01005 | |

| Speed | 7-10s | |

| Accuracy | ≥99.9% | |

|

Equipment |

Dimensions | 1000mm (L) * 1300mm (W) * 1920mm (H) |

| Weight | 850kg | |

| Power supply | AC110-220V 50/60HZ | |

| Max power | 1500W | |

| Industrial PC | I3-7100 CPU, 8G RAM, 240GB SSD | |

| Displayer | 24” HDMI LCD | |

|

Other functions |

Code scanning | Barcode and QR code |

| Label printing | Print material code and quantity automatically after counting. | |

| Management system connection | MES, ERP etc. | |

|

Safety |

Radiation leakage | No leakage, international standard: ≤1μSv/h. |

| Back door safety interlock | Once users open the back door, X-ray tube will power off immediately. When the back door is open, users can’t turn on the X-ray. | |

| Tray collision protection | There are steel plates protect the tray from collision when it comes out. | |

| Anti-pinch safety light curtain | Once the hand enters the movement range of the tray, the safety light curtain will be triggered, the tray will stop immediately, and the software will pop up a prompt at the same time. Users can continue only the hand leaves and click confirm on the prompt. | |

| Emergency stop | In front of the operation position, press to power off. | |

|

Speed and Accuracy |

|||||||||||||||||||||||||||||||||||

|

Till now, the counting time and accuracy of various sizes of reels as below. It will be faster and more accurate as our algorithm updates. |

|||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

|

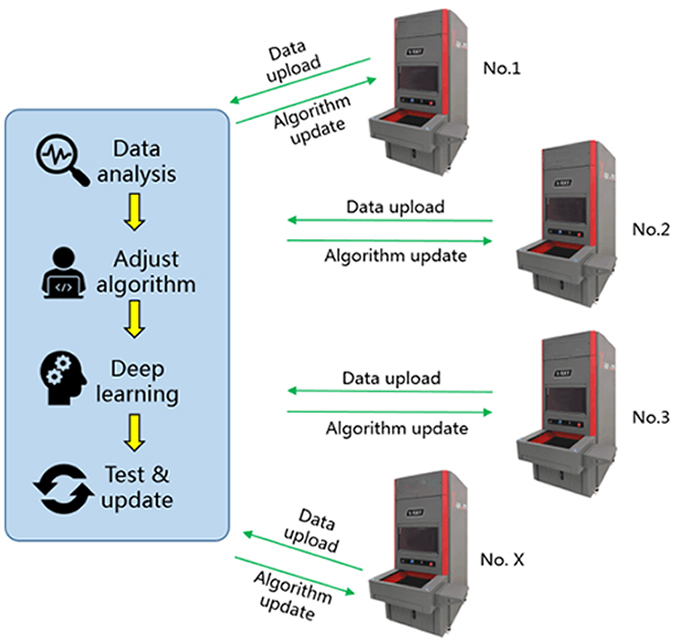

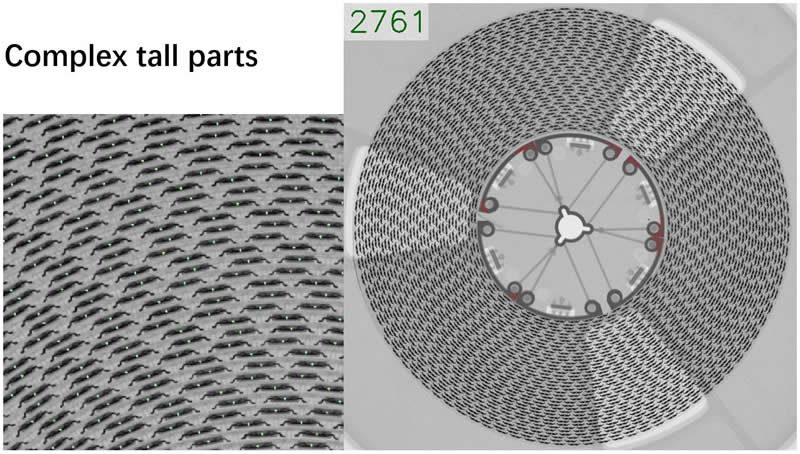

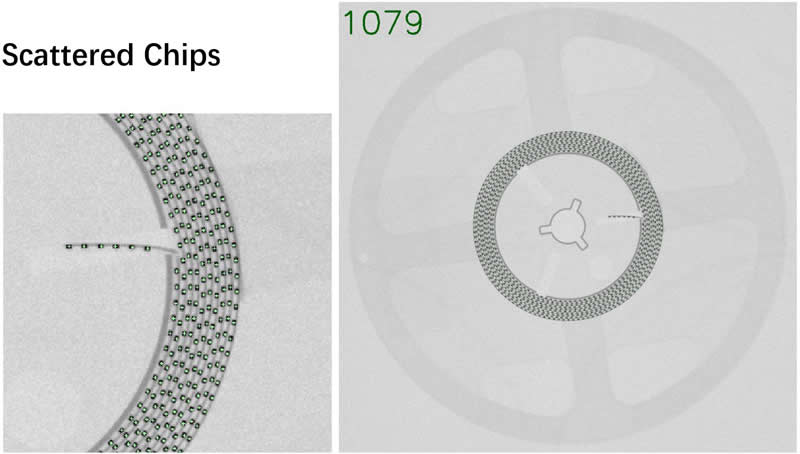

Artificial intelligence deep learning algorithm |

|||||||||||||||||||||||||||||||||||

|

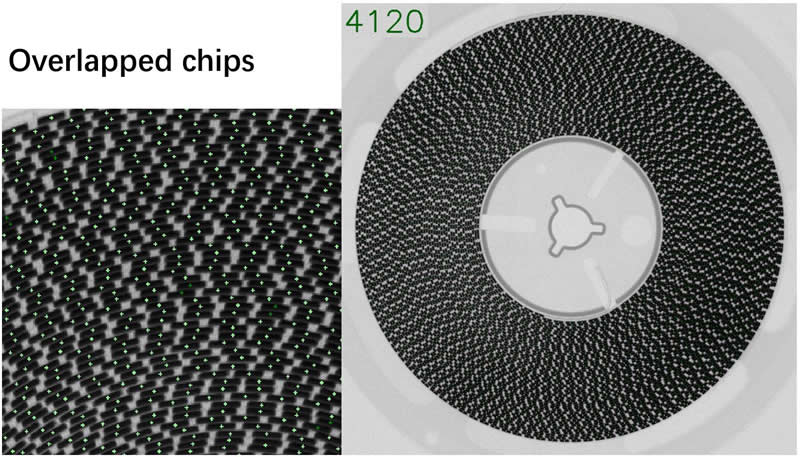

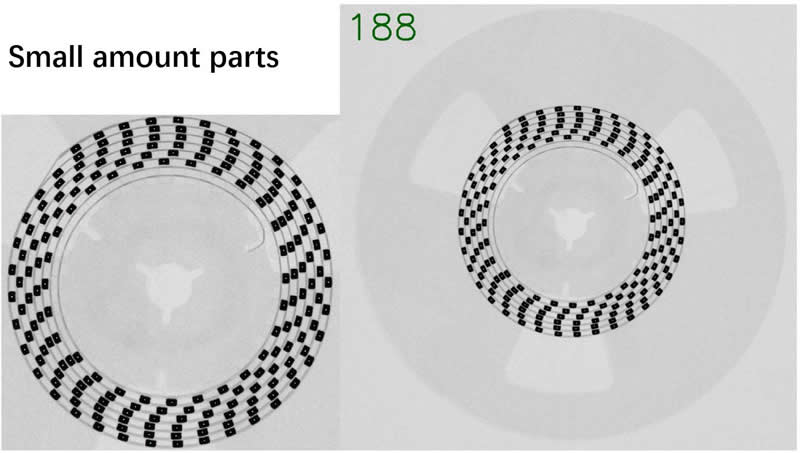

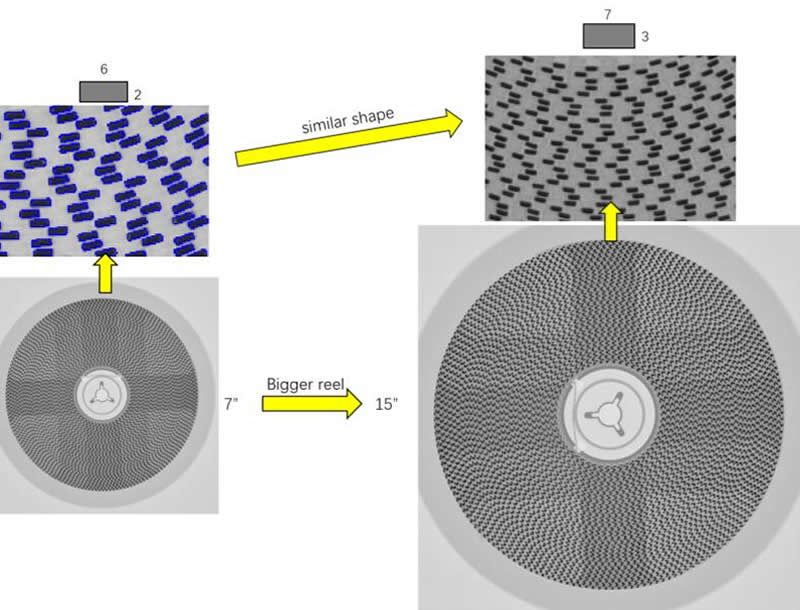

Our counting software uses a powerful artificial intelligence deep learning algorithm. No need to bind components to algorithm, we use AI to automatically identify components and automatically apply algorithm. The algorithm can learn the counted component data, such as: |

|||||||||||||||||||||||||||||||||||

|

1. Aspect ratio |

|||||||||||||||||||||||||||||||||||

|

2. The angle of each corner of the component; |

|||||||||||||||||||||||||||||||||||

|

3. Slope between components from inside to outside; |

|||||||||||||||||||||||||||||||||||

|

4. Deformation of component images from the inside to the outside, etc. |

|||||||||||||||||||||||||||||||||||

|

As the number of components counting increases, the results become more and more accurate. When we need to count similar components, or larger trays, we can easily handle it. |

|||||||||||||||||||||||||||||||||||

|

|

|

Cloud database |

|

Every 1Clicksmt X-ray counter can connect to our cloud database. The data and images of the machine will be uploaded to the cloud, and the machine will automatically download the latest database. Our engineers also optimize the algorithm in the background according to the images and data collected by each machine, and regularly update it to the database for customers. |

|

Over time, the accuracy of counting will be closer to 100%, and the coverage of component types will become wider and wider. When a machine counts a new kind of component, if the data of this kind of component is stored in our database, our software can directly call the data, which brings users higher efficiency, accuracy and coverage. |

|

|

|

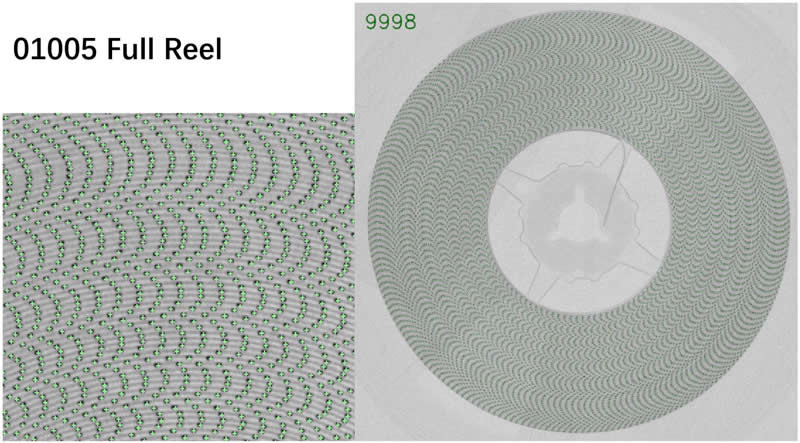

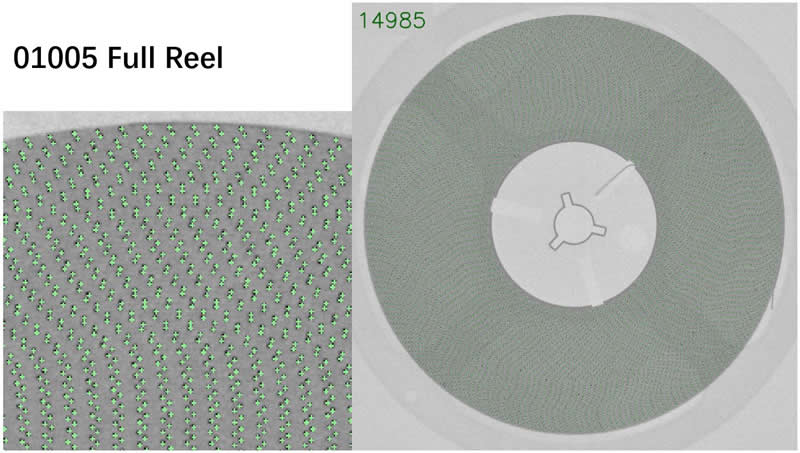

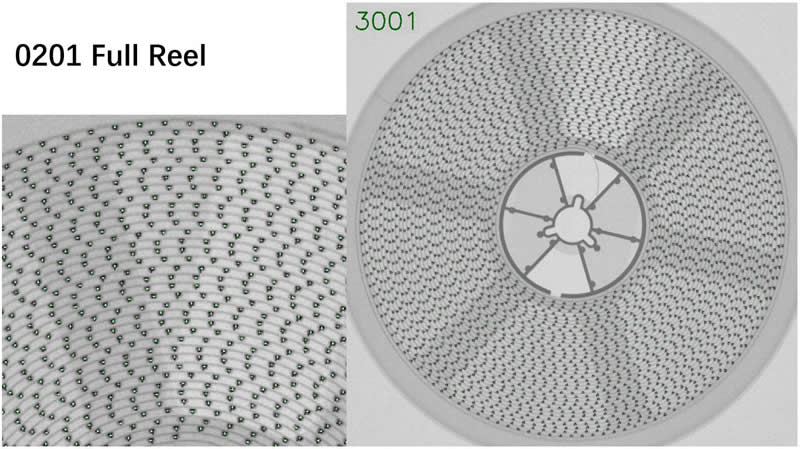

Sample images |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 review for Donec eu furniture

Related Products

X-Ray machine SoYi-R7

- Model: SoYi-R7

Add a review

Your email address will not be published. Required fields are marked