- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

Automatic Screw Driving Machine SY-S12T

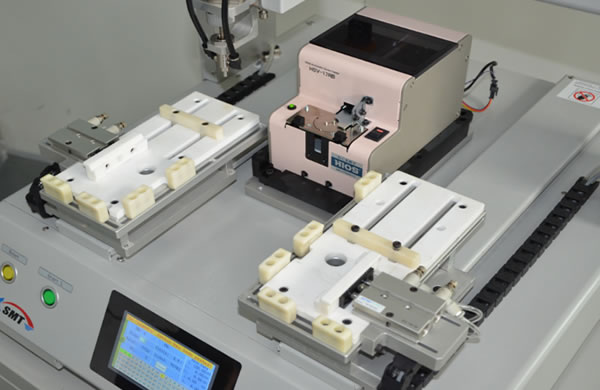

SY-S12 series machine is equipped with high quality Japan made HIOS screw driver and Quicher screw feeder, Double work station realize non-stop running, greatly improve production efficiency.

Automatic Screw Driving Machine SY-S12T

×|

|

High quality robot with step motor controlled by PLC and touchscreen. |

|

|

High quality Japan made HIOS high quality screw driver and screw feeder (optional) |

|

|

Double work station realize non-stop, improve production efficiency. Support placing products on the front side of machine and taking out on back side of machine. |

|

|

Customized fixture is available to variety of products. |

|

|

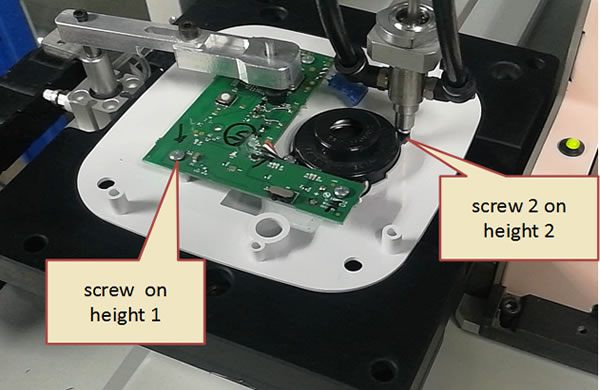

SY-S12T/L/M Series with optional A axis can automatically adjust screw driving height, capable to drive screws on different plane height. |

|

Automatic Screw Driving Machine SY-S12 Series Description: |

|

1. High quality 4 axis(X/Y1/Y2/Z) robot with step motor control ensures machine run stably . |

|

2. PLC and touch screen control system with full english interface, easy to operate . |

|

3. Equipped with high quality Japan made HIOS screw driver and screw feeder (optional). |

|

4. Double work station realize non- stop, improve production efficiency. |

|

5. Customized fixture is available to variety of products. |

|

6. Support placing products on the front side of machine and taking out on back side of machine. |

|

7. Screw missing detection and loose screw detection are standard configuration. |

|

8. SY-S12T/L/M Series with optional A axis is able to drive screws on different plane height. |

|

9. Screw floating height detecting function is optional to ensure each screw is driven to bottom and tightend. |

|

Automatic Screw Driving Machine SY-S12 Series Specification: |

|||

|

Model |

SY-S12T |

SY-S12L | SY-S12M |

|

Screw driving head quantity |

1 |

1 | 1 |

|

Work table quantity |

2 |

2 | 2 |

|

Work table size(mm) |

W120mm*D200mm*H60 |

W180mm*D250mm*H60 | W250mm*D300mm*H60 |

|

Drive system |

X/Y/Z axis step motor control |

X/Y/Z axis step motor control | X/Y/Z axis step motor control |

|

Positioning Repeatability |

±0.05mm |

±0.05mm | ±0.05mm |

|

Screw picking method |

vaccum picking |

vaccum picking | vaccum picking |

|

Screw driving speed |

max 1.5 pcs/sec |

max 1.5 pcs/sec | max 1.5 pcs/sec |

|

Power |

300W |

300W | 300W |

|

Power Supply |

1P, AC110V/220V, 50/60 HZ |

1P, AC110V/220V, 50/60 HZ | 1P, AC110V/220V, 50/60 HZ |

|

Machine size(mm) |

W550mm*D650mm*H650mm |

W650mm*D650mm*H700mm | W800mm*D650mm*H700mm |

|

Weight |

60KG |

70KG | 75KG |

|

air pressure requirement |

0.4-0.7Mpa |

0.4-0.7Mpa | 0.4-0.7Mpa |

| Specification of screws for standard Quicher screw feeder | One type of screw from M1.0 to M3.0(Others can be customized) | One type of screw from M1.0 to M3.0(Others can be customized) | One type of screw from M1.0 to M3.0(Others can be customized) |

| Applicable Screw Length(under head) |

Up to 20mm |

Up to 20mm | Up to 20mm |

|

Standard HIOS screw driver |

Standard Torque is 1~5kgf.cm (0.1~0.5N.M). Others can be customized | Standard Torque is 1~5kgf.cm (0.1~0.5N.M). Others can be customized | Standard Torque is 1~5kgf.cm (0.1~0.5N.M). Others can be customized |

|

Automatic Screw Driving Machine SY-S12 Series configuration: |

|

Standard configuration: |

|

● Automatic screw driving machine |

|

● 4 aix step motor and driving system. |

|

● Quicher screw feeder (OHTAKE NSRI)*1set (One type of screw from M1.0 to M3.0, Others can be customized) |

|

● HIOS high quality screw driver *1set (Standard is CL-2000 or CL-3000 or CL-4000 one set; Others can be customized) . |

|

● 1 year parts warranty . |

|

Optional configuration: |

|

● A axis for screws needed to be driven on different plane height |

|

● Screw floating height detection . |

|

● Customized fixture |

0 review for Donec eu furniture

Related Products

Automatic Screw Driving Machine SY-S22T

- Model: SY-S22T

Automatic Screw Driving Machine SY-S24S

- Model: SY-S24S

Embeded Screw Driving Machine ASD-600S

- Model: ASD-600S

Inline Screw Driving Machine ASD-600i

- Model: ASD-600i

Add a review

Your email address will not be published. Required fields are marked