- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

Automatic Soldering Robot H351

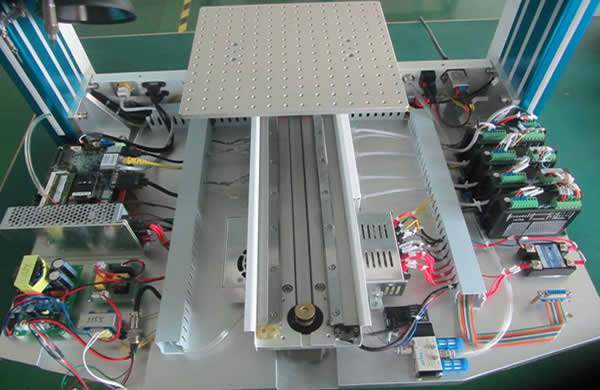

H351 is a 5 axis soldering robot with X,Y,Z,R, and solering wire feeding motion system. It is equipped with 400W high frequency heating systerm with rapid heat recovery, soldering tip is easy to be exchange with low cost. Break-tin automatic solder wire feeder can reduce burst tin that causes flux remaining on PCB when soldering under high temperature to improve the soldering quality. Self-developed software under windows 7 English OS is easy to operate.

Available Options

Automatic Soldering Robot H351

×|

|

● General: Advanced industrial design make machine looks very beautiful, solid structure and X/Y/Z/R step motor with it's motion control system ensure machine run smoothly and precisely. |

|

|

● Motion system: 5 axis with X,Y,Z,R, and soldering wire feeding motion system are all controlled by one combined 5 axis motion control card with PC, so it can integrate all the functions into one software like programming, soldering time setting, solder wire feeding length setting, motion control. it makes machine running more stable and easy to operate.The repeated accuracy of 24-hour “NRZ” continuous motion<0.06mm. |

|

|

● Heating system: High frequency induction heating system with 400W power (600W is optional), it has rapid temperature recovery time. |

|

|

● Heating system: Touch screen control panel for temperature setting. |

|

|

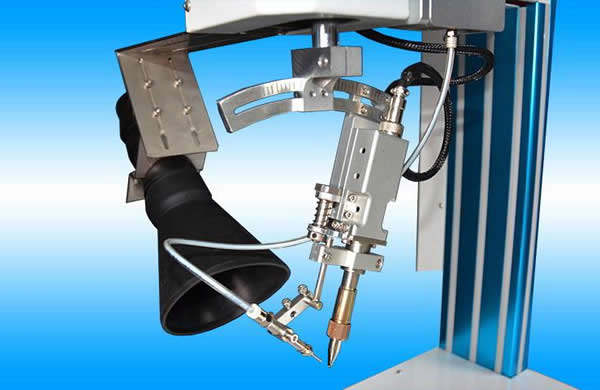

● Soldering head: Heating element adopt silver coil which can ensure long lifetime. Induction type soldering tip can be easliy changed with lower cost. heating speed is very fast.With the rotation axis, iron components can rotate 330 degrees. fully meet the differeent angle of welding products. Mobile smoke cover: Mobile smoke cover (optional ) can be easily connected with smoke extractor or exhaust system in workshop, which can provide a clean work environment. |

|

|

● Soldering tip: Various soldering tips can meet different process requirement. customized solering tips is also available. |

|

|

● Solder wire feeding: High precision solder wire feeding system with wire pierecing wheel which can reach 0.1mm feeding accuracy and reduce the problem of flux remaining on PCB after soldering, improve the soldering quality. |

|

● Broken tin wire |

|

● Solder tip cleaner: It is equipped with automatic soldering tip cleaning device, which can improve soldering quality. Adopt electric steel brush to clean the soldering tip, which has high efficiency. It can quickly remove the residual tin on the soldering tip. Adopt motion control card and motor, the clean time can be set free. Cleaning speed can be adjusted. |

|

|

● Solder tip cleaning |

|

|

● Humanized operation: H351 adopt self-developed software based on windows 7 English operation system, use touchscreen with wireless controller and teach method for programming. |

|

|

● Teaching pendant: A wireless remote control teaching controller is easily used for programming. |

|

|

● Standard universal fixture. |

|

|

● Customerized fixture according to customer's requirement (option). |

|

● Optional CCD: High resolution CCD, it has mark positioning function, and can automatically correct the coordinate offset . |

H351 Automatic Soldering Robot Features

|

● Advanced industrial design, beautiful shape, solid structure break traditional framework, which is more reasonable and practical. |

|

● X,Y,Z,R, and soldering wire feeding motion system are all controlled by one combined 5 axis motion control card with PC, so it can integrate all the functions into one software like programming, soldering time setting, solder wire feeding length setting,motion control. it makes machine running more stable and easy to operate. |

|

● X,Y,Z,R axis adopt quality step motor with it's contorl system, make machine run smoothly and precisely. |

|

● It is equipped with automatic soldering tip cleaning device, which can improve soldering quality and prolong lifetime of soldering tip. |

|

● H351 is equipped with industrial PC with windows 7 English operation system, use touchscreen with wireless controller and teach method for programming, makes programming very easy. |

|

● Break tin solder wire feeding system can pierce holes when feeding solder wire, it can reduce burst tin that causes flux remaining on PCB when soldering under high temperature to improve the soldering quality. solder wire feeding accuracy can reach 0.1mm. |

|

● 400W high frequency induction system has rapid temperature recovery time, heating element adopt silver coil which can ensure long lifetime. soldering tip can be easily changed with lower cost. |

|

● Self-developed advanced software, fool-style programming with wireless controller like play game, all parameters can be set in one program, such as moving path, solder wire feeding quantity, soldering time etc, very easy to use. |

|

● Optional smoke cover and smoke extractor can provide a very clean work enviroment. |

| ● Various soldering tips can meet different process requirement. customized solering tips is also available. |

|

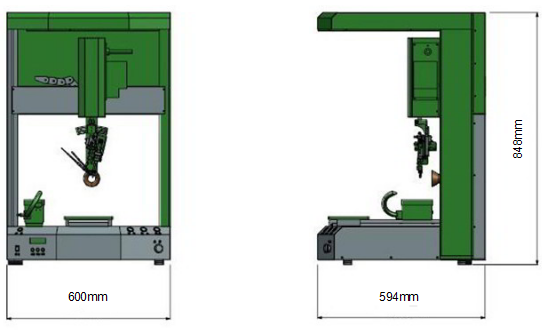

Structure drawing

|

|

H351 - Specifications |

|||

|

Model |

G351 |

H351 |

H352 |

|

Axes |

X/Y/Z/R/wire feeder |

X/Y/Z/R/wire feeder |

X/Y1/Y2/Z/R/wire feeder |

|

Machine travel(X/Y/Z/R) |

Standard : 470/320/90mm/330° With safety light curtain: 400*280mm*90mm/330° |

Standard : 320/320/90mm/330° With safety light curtain: 250/280/90mm/330° |

Standard: 235/320/90mm/330°*2pcs With safety light curtain: 220/300/90mm/330°*2pcs |

|

Max running speed(X/Y) |

500mm/s |

500mm/s | 500mm/s |

|

Repeat positioning accuracy |

±0.06mm |

||

|

Platform load |

3KG |

||

|

Temperature Range |

180℃-450℃ |

||

|

Min Solder wire feeding length |

0.1mm |

||

|

Solder wire feeder |

standard 1.0mm-1.2mm feeder(break tin),optional 0.6-0.8mm feeder(without break tin) |

||

|

Programming method |

Manual teach(Touch Screen + Wireless Remote) |

||

|

Power supply |

single-phase: AC 220V/110V f : 50HZ/60HZ |

||

|

Air pressure |

0.4-5kg/cm² |

||

|

Work environment |

0℃~40℃ |

||

|

Machine size |

L750*W594*H854mm(not including safety light curtain ) |

L600*W594*H848mm(not including safety light curtain ) |

L750*W594*H854mm(not including safety light curtain ) |

|

Weight |

105kg |

85kg | 105kg |

|

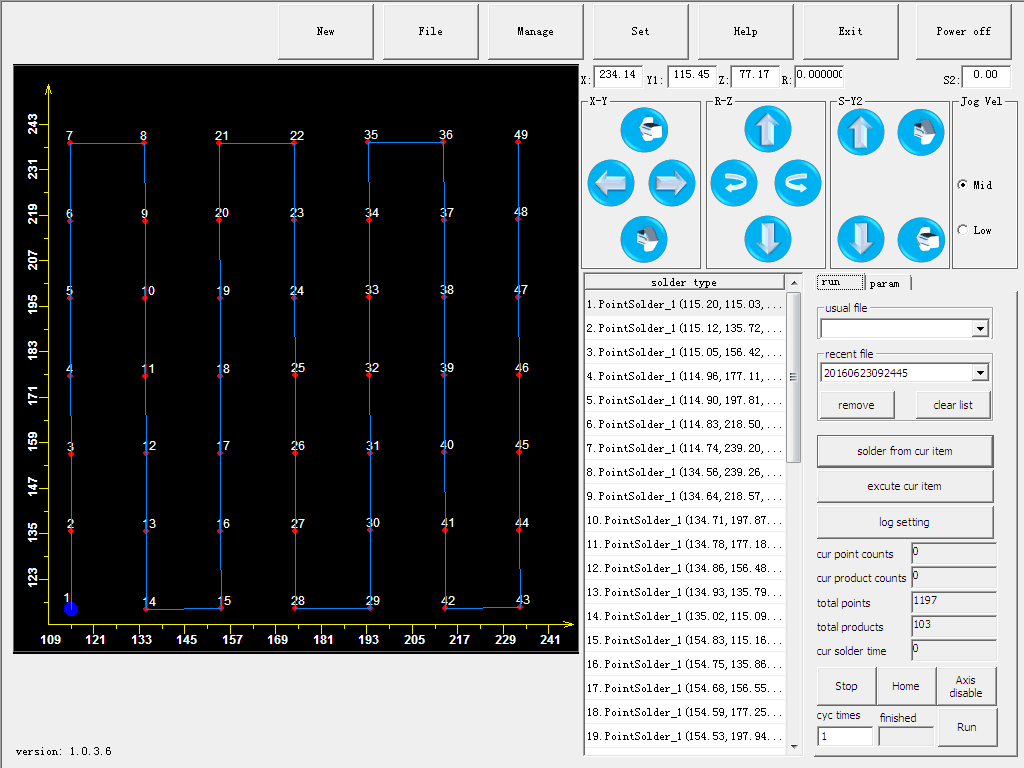

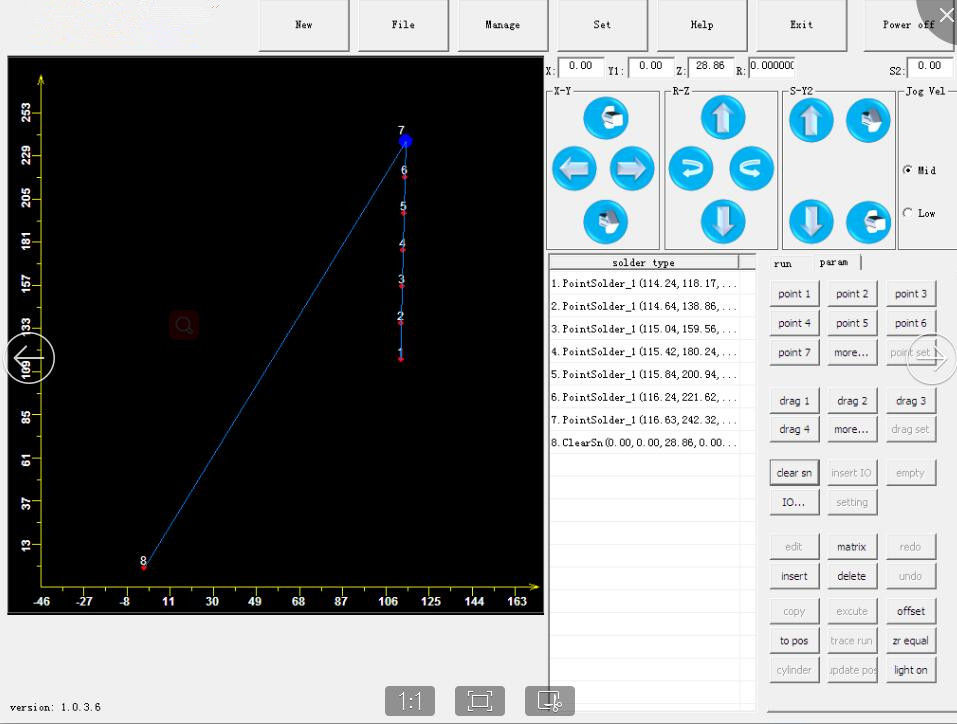

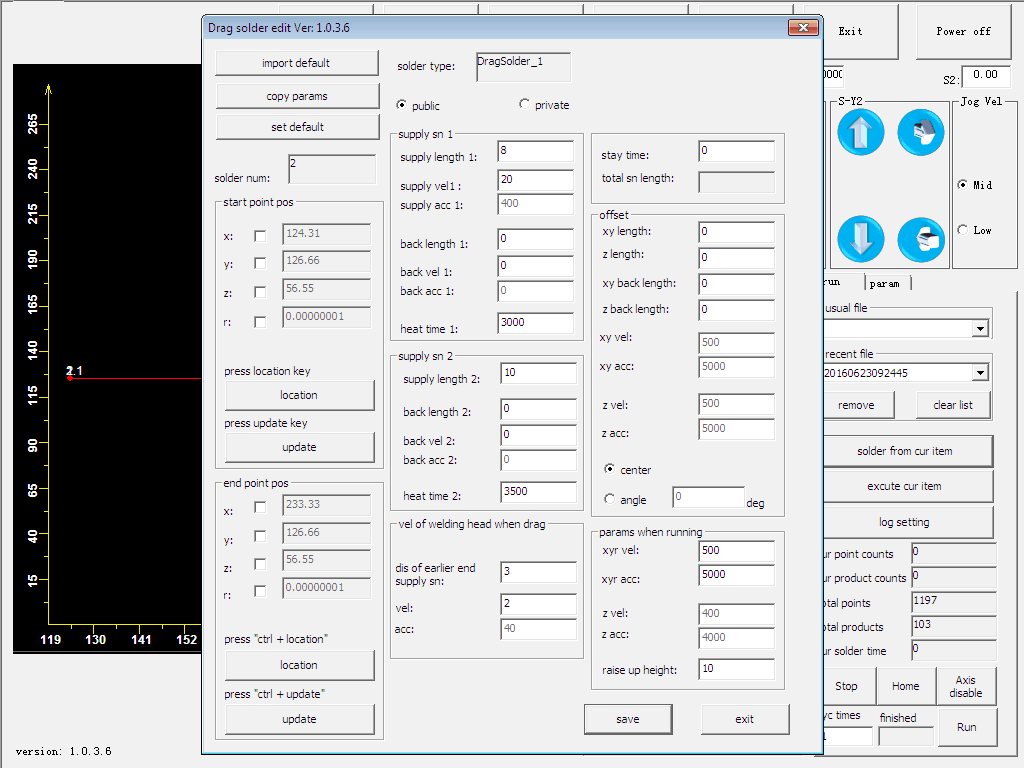

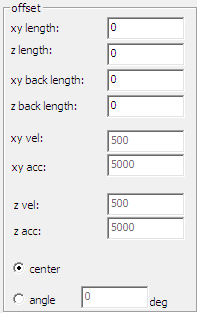

Programming

Self-developed advanced software, fool-style programming with wireless controller like play game, all parameters can be set in one program, such as moving path solder wire feeding quantity, solder wire feeding speed, running speed, soldering time etc, very easy to use. The self-developed software & hardware researched enjoy free upgrade in the whole service life.

|

|

|

|

Programming

Bulk modification of similar soldering spots can be set without modifying one by one. Insert or delete soldering spot coordinates in any position without affecting other soldering spots.

|

|

|

|

Programming

Easier setting operation for spot soldering and drag soldering; built-in data can be called out at any moment; The program can store an unlimited number; Real-time display the current completion of the number of soldering products and the current number of soldering points.

|

|

|

Programming

Every program can set different types of spot soldering and drag soldering according to the different size of the soldering pad. Both spot soldering and drag soldering parameters can be set to 100 groups. The display screen of coordinatometer shows the track of all soldering spots clearly and makes program modification more visually. Real-time display of the current soldering track on the touch screen.

|

|

|

Humanized operation: Full touch operation + fool-style programming, in which case any setting can be realized by click. |

|

|

|

|

|

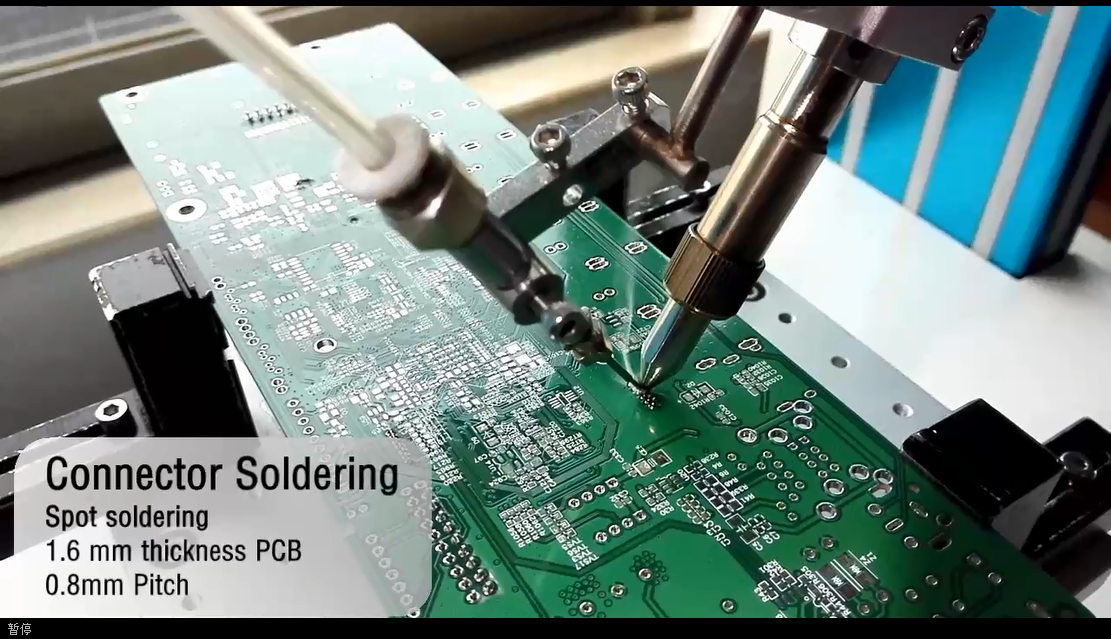

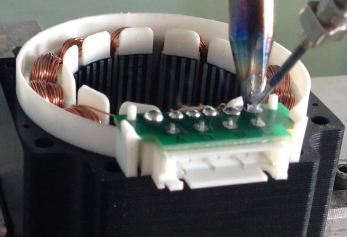

High heat soldering point(connector) |

Fine pitch soldering point |

|

|

|

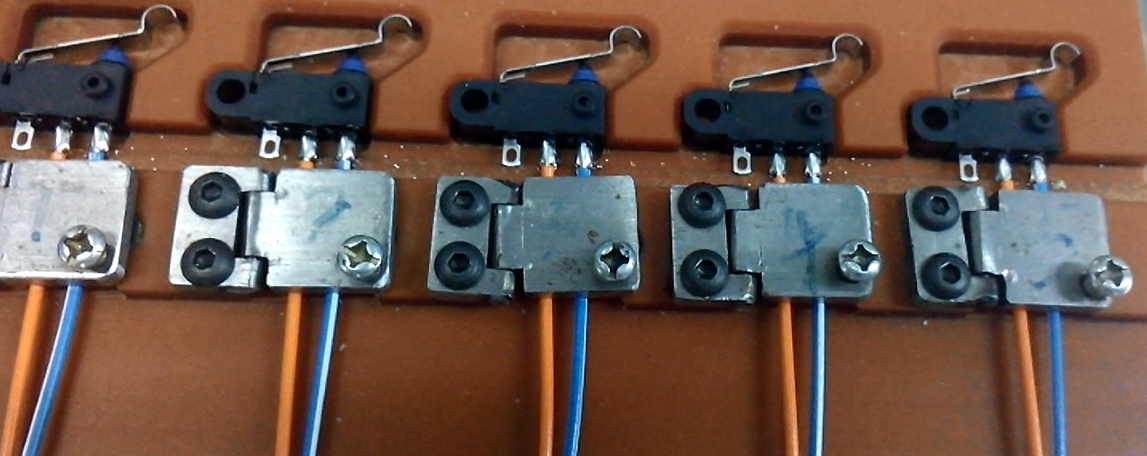

USB soldering |

Micro switch soldering |

|

|

|

| Motor soldering | |

|

Standard configuration : |

|

● Automatic Soldring Robot. |

|

● Industrial PC,12"LCD touch screen. |

|

● X,Y,Z,R and wire feeding driving system. |

|

● 1.0-1.2mm solder wire feeder (break tin) |

|

● 400W high frequecy induction heating system. |

|

● wireless controller. |

|

● Universal fixture 1set |

|

● Soldering tip*3pcs |

|

● Steel brush*10pcs |

|

● 1 year parts warranty |

|

Optional configuration : |

|

● Customized fixture. |

|

● Smoke exhaust cover. |

|

● Smoke extractor. |

|

● Safety light curtain. |

|

● CCD for fiducial mark recognition. |

|

● 0.6-0.8mm solder wire feeder (without break tin function ) |

|

● Optional 600 W soldering station instead of 400 W soldering station.(Only for a large amount of heat absorption products) |

0 review for Donec eu furniture

Related Products

Automatic Soldering Robot iBot-1

- Model: iBot-1

Add a review

Your email address will not be published. Required fields are marked