- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

Linking Conveyor Series

Linking Conveyor Series

This unit is used to link between production machines or board handling units.

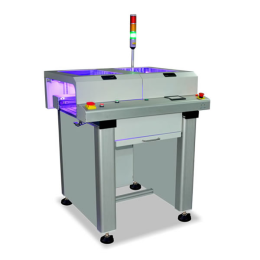

Inspection Conveyor Series

Inspection Conveyor Series

The inspection conveyor is used when frequent visual inspection of PCB's is required in the PCB assembly line.

High Version Conveyor Series

High Version Conveyor Series

This unit is used to link between production machines or board handling units.

High Version Reject Conveyor Series

High Version Reject Conveyor Series

The unit installed after AOI for separated NG board for visual inspect and good board will pass through without stopping.

Reject Conveyor Series

Reject Conveyor Series

The unit installed after AOI for separated NG board for visual inspect and good board will pass through without stopping.

Telescopic Conveyor Series

Telescopic Conveyor Series

The unit provides a 'normal open' passage in a PCB assembly line. An integrated conveyor segment slides across the opening to deliver PCB to downstream machine.

Coating Conveyor Series

Coating Conveyor Series

This unit is used as a visual inspection station for operators controlling the boards right after a conformal coating line.

Manual Lift Gate Conveyor Series

Manual Lift Gate Conveyor Series

By manual lifting the conveyor section, access is gained to the rear of the line.

Single Magazine Loader Series

Single Magazine Loader Series

The unit loads your production line automatically by pushing PCB’s out of a magazine onto the conveyor of the downstream machine.

Multi Magazine Loader Series

Multi Magazine Loader Series

The unit loads your production line automatically by pushing PCB's out of the magazine onto the conveyor of the downstream machines. Full magazines are inserted at an ergonomic low level.

Vaccum and magazine combo loader

Vaccum and magazine combo loader

The unit loads your production line automatically by pushing PCB's out of the magazine onto the conveyor of the downstream machines. Full magazines are inserted at an ergonomic low level.

Destacker Series

Destacker Series

A large stack of unpopulated PCB's is placed above the ESD beltconveyor. Unique separation cams take one PCB from the bottom of the stack and lowers it onto the ESD belt conveyor.