- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

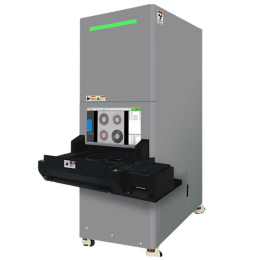

S-350/S-600 Series Desktop SPI Machine

S-350/S-600 series offline SPI were designed to make in-house offline SPI, This series SPI apply to small and normal size PCB, and satisfy customers with small investment to inspect printing quality, moving convenience, simple operation and high accuracy, the highest cost performance options for customers. and acceptable by CE certification.

Available Options

S-350/S-600 Series Desktop SPI Machine

×|

|

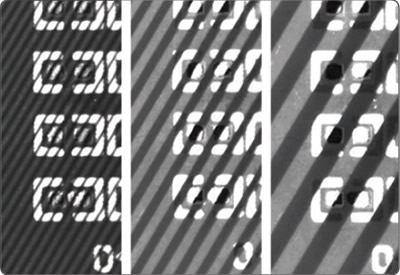

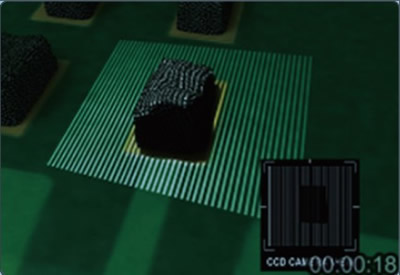

Programmable spatial light modulation(PSLM) The use of PSLM combined with the PMP to achieve 100% high-precision solder paste 3D measurement in SMT production line. Using PSLM technology, changed the traditional way of generating 3D Struct Light, the traditional glass grating moire required mechanically,driven by a piezoelectric motor (PZT). By using PSLM, no need glass grating and mechanical parts any more. The elimination of the mechanical drive and moving parts, greatly improving the ease of use,and avoid mechanical wear and reduce maintenance costs. |

|

|

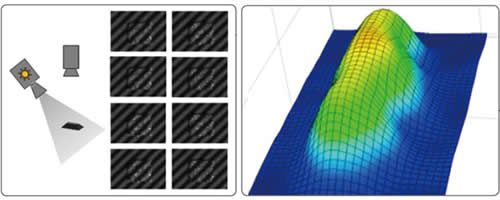

Phase modulation profiler metry. By using the Stop & Catch methods combined with multiple image acquisition, realize highly repeatable 3D results on the solder paste measurement. Compared to conventional scanning just take one pictures only on the solder paste a scan sampling, multiple image acquisition greatly enhancing the accuracy and reliable test results. |

|

|

3D Diffuse lighting & active RGB 2D light source Patented D-Lighting technology achieves full light spectrum detect ability. It is perfect solution to solve the shadow effect and reduce noise interference during 3D measurement. |

|

|

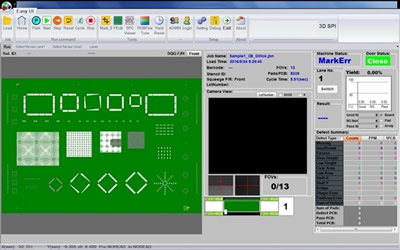

5 minutes of programming and one key operation. Operator can easily make program in 5 minutes by Gerber loading and friendly interface. one button operation dramatically reduce the training efforts. |

| S-350/S-600 Series Desktop SPI Machine Features: |

|

1. The use of PSLM combined with the PMP to achieve 100% high-precision solder paste 3D measurement in SMT production line. Using PSLM technology, changed the traditional way of generating 3D Struct Light, the traditional glass grating moire required mechanically, driven by a piezoelectric motor (PZT). By using PSLM, no need glass grating and mechanical parts any more. The elimination of the mechanical drive and moving parts, greatly improving the ease of use, and avoid mechanical wear and reduce maintenance costs. |

|

2. By using the Stop & Catch methods combined with multiple image acquisition, realize highly repeatable 3D results on the solder paste measurement. Compared to conventional scanning just take one pictures only on the solder paste a scan sampling, multiple image acquisition greatly enhancing the accuracy and reliable test results. |

|

3. Patented D-Lighting technology achieves full light spectrum detect ability. It is perfect solution to solve the shadow effect and reduce noise interference during 3D measurement. |

|

4. Gerber data conversion and import, achieve automatic detection of the entire board. Manual "Teach" function realize user-friendly programming and test job generation in case of no Gerber data situation. |

|

5. Friendly and simple user interface, five minutes of programming and one key operation. |

|

6.Powerful "Statistical Process Control (SPC)", provide a plenty of tools, user-friendly real-time monitoring, reduce defects caused by poor solder paste printing and improve final product quality. |

|

S-350/S-600 Series Desktop SPI Machine Specifications |

||

|

Model |

S-350 |

S-600 |

|

Measurement Principle |

3D white light PSLM PMP(programmable spatial light modulation) | 3D white light PSLM PMP(programmable spatial light modulation) |

|

Measurements |

volume, acreage, height, XYofiset, shape |

volume, acreage, height, XYofiset, shape |

|

Detection of defective range |

missing print, insufficient solder, excessive solder, bridging, offset, mal-shapes, surface contamination | missing print, insufficient solder, excessive solder, bridging, offset, mal-shapes, surface contamination |

|

Camera Pixel |

Standard : 2M |

Standard : 2M |

|

Lens Resolution |

20um(FOV: 26*20mm) |

20um(FOV: 26*20mm) |

|

FOVSpeed |

1.5s/FOV |

1.5s/FOV |

|

Quantityof lnspection Head |

Single Head |

Single Head |

|

RGB LightSource |

standard configuration |

standard configuration |

|

Maximun Meauring Height |

Standard :±350um |

Standard :±350um |

|

Maximun Measuring Heightof PCB Warp |

±2mm |

±2mm |

|

Minimum Pad Spacing |

150um |

150um |

|

Maximum PCB Size |

L460xW350mm |

L700xW600mm |

|

SPC Statistics |

Standard configuration |

Standard configuration |

|

Geiber & CAD data loading |

Standard configuration |

Standard configuration |

|

Computer |

Windows 10 OS, English version |

Windows 10 OS, English version |

|

Equipment Diemension |

810x 890x530mm |

1500x 1100x600mm |

|

Power & AirPressure |

AC, 220V, 50/60hz |

AC, 220V, 50/60hz |

|

Offline SPI machine S350/600 Includes: |

|

Standard configuration: |

|

● Offline SPI machine S350/600 |

|

● 2M pixels industrial camera &telecentric lens |

|

● Single 3D inspection head (PSLM PMP) |

|

● SPC software |

|

● One year warranty |

0 review for Donec eu furniture

Related Products

Merlin A-400P Offline Automated Inspection System

- Model: Merlin A-400P

Falcon SA-510F SMT Component Automated Inspection System With Flipper

- Model: Falcon SA-510F

X-Ray Counter SoYi-C3

- Model: SoYi-C3

X-Ray Counter SoYi-C2

- Model: SoYi-C2

SA-500 SMT Component Automated Inspection System

- Model: SA-500

Add a review

Your email address will not be published. Required fields are marked