- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

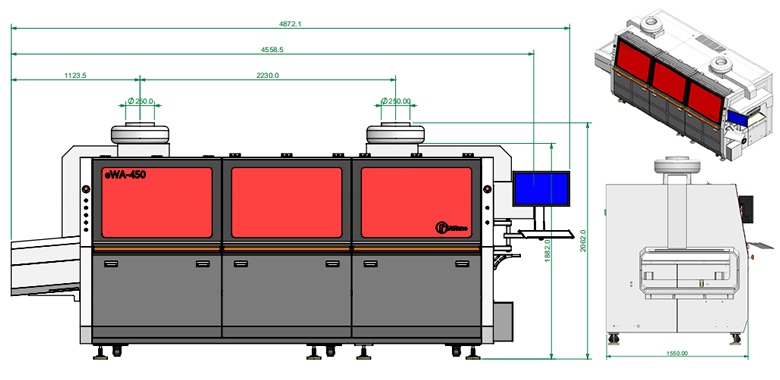

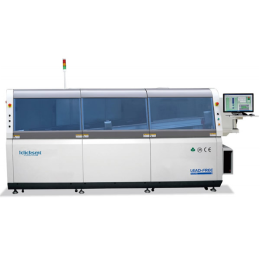

Lead Free Wave Solder Machine eWA Series

PC+PLC control system High quality sprayer driven by stepper motor 3 Bottom preheating zone, 1 Top preheating zone Hot air motor speed adjustable Full Titanium dual wave solder pot Solder pot in/out, up/down automaticlly Heavy duty titanium finger conveyor Max PCB width 450 mm

Available Options

Lead Free Wave Solder Machine eWA Series

×|

eWA series Lead Free Wave Solder Machine Structure: |

|

|

|

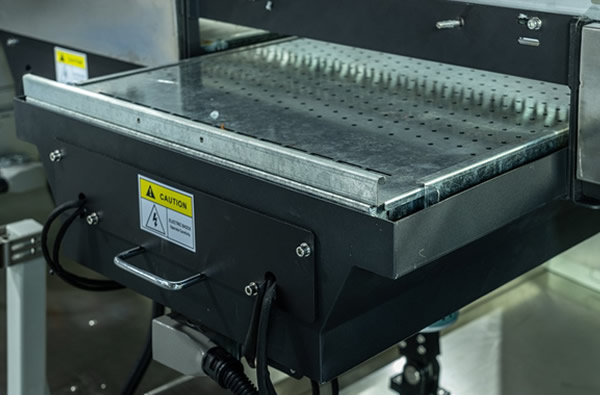

Conveyor System In-loading system: which can connect with the insertion conveyor directly, the sensor at bottom for counting and spray fluxer on/ off. |

|

|

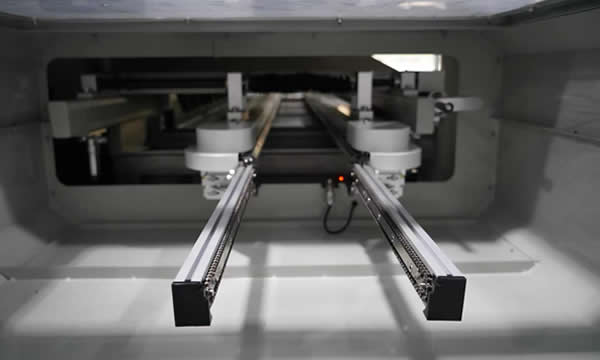

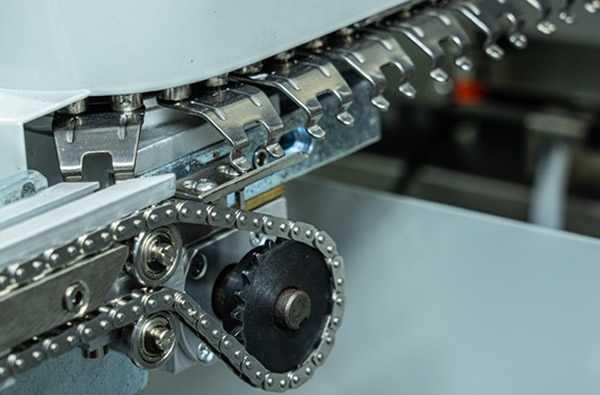

Conveyor System Standard: Heavy duty type Ti finger for standard conveyor. |

|

|

Flux System Stepper motor/driver etc, make sure the spray nozzle moving at needed speed smoothly. |

|

|

Flux System sprayer's flow, flux shape, automization etc adjustable, so to meet a perfect flux applying performance. |

|

|

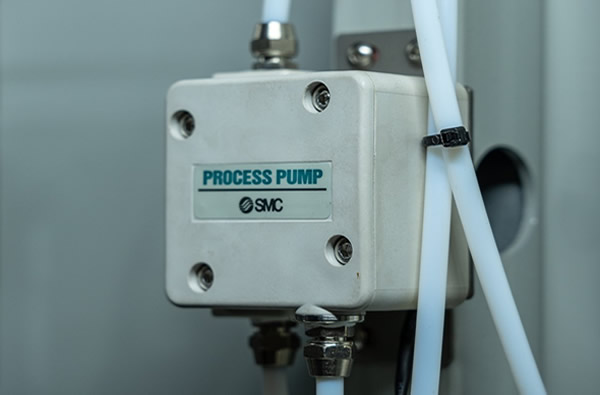

Flux System Flux is adding via a SMC pump automaticlly, save operator's time and job. |

|

|

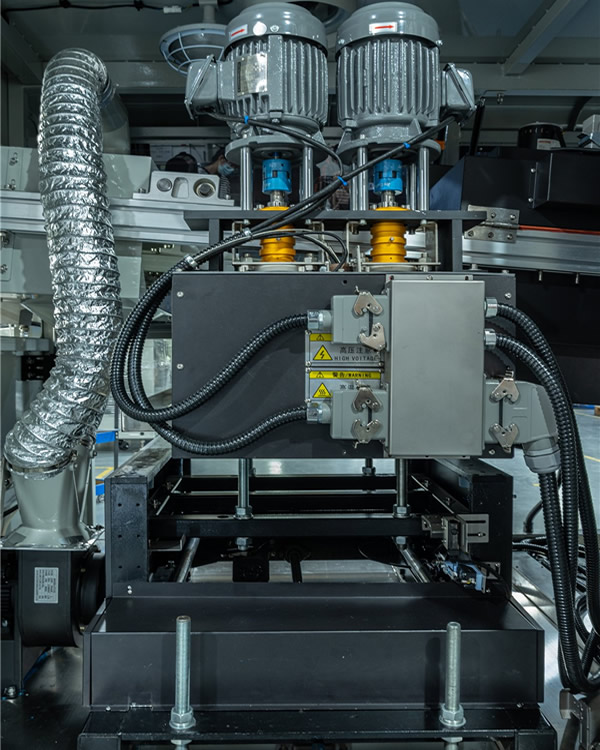

Preheating System Standard equipped with 3 hot air convection preheating zone at bottom, and 1 top hot air convection preheating zone. |

|

|

Preheating System 3 phase hot air motor controlled by inverter, speed is freely adjustable in the software. |

|

Preheating System Preheating module can be easily taken out for maintenance. |

|

|

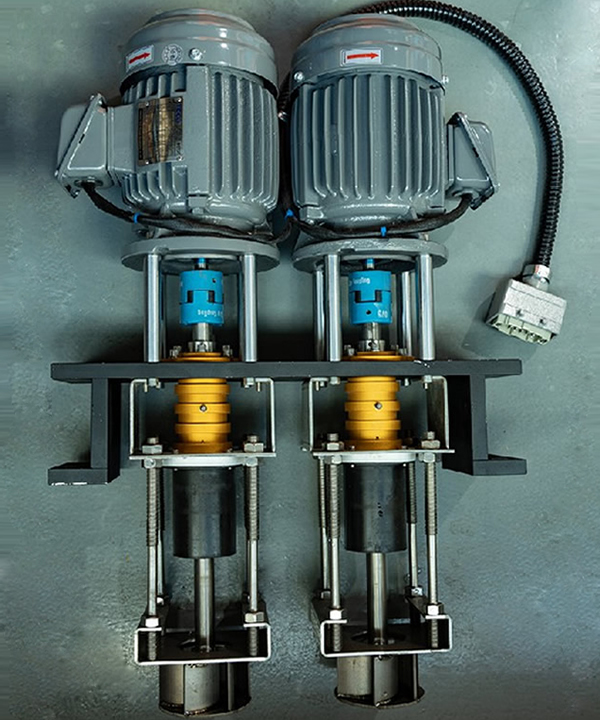

Soldering System Ti material made solder pot, capable for Lead free. Two wave nozzle, one is for turbulent wave and another is for flat wave. |

|

|

Soldering System Solder pot in/out, up/down automaticlly. |

|

|

Soldering System Special design for wave driving system, it can be easily taken out for maintenance. |

|

|

Cooling System Powerful cooling motor with top/bottom cooling system. |

|

|

Exhausting System Standard equipped with 2 exhausting blower, which can directly exhaust fume outside. |

|

|

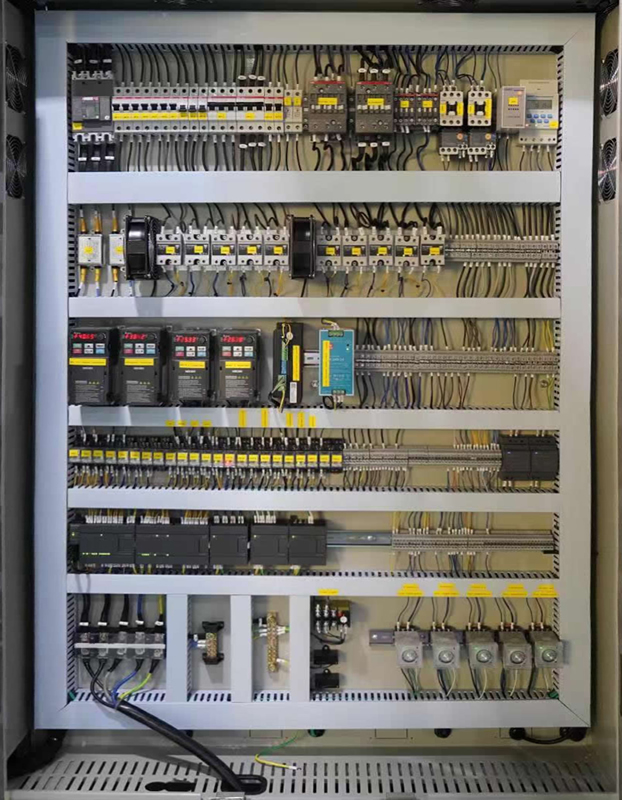

Electrical System All brand electrical parts, such as SIMENS PLC, ABB breaker, DELTA inverter, etc all wiring cetificated by CE. |

|

|

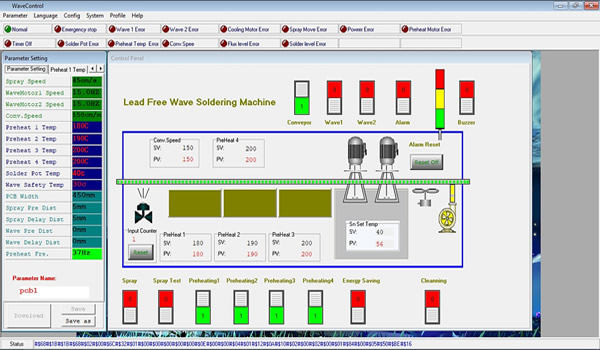

Software Full English software based on Windows 10 OS, easy to operate. |

|

eWA series Lead Free Wave Solder Machine Features |

|

● New industrial apperance design makes machine more beautiful. |

|

● PC+ PLC control system form a stable,safe and efficient controlling system, easy for operation. |

|

● Simple software interface, Full English interface is very easy for operation. |

|

● The one-week timer can make the machine turn on/off automatically to melt the solder before operator come to work. |

|

● The specially guiding rail with strong support to reduce the deformation. |

|

● Sprayer driven by stepper motor, the speed and spraying width can be set on software. |

|

● High quanlity sprayer provides perfect atomization performance of the flux. |

|

● Adding flux automatically, When flux is lower than limit, it will switch on the pump to feed flux in automatically. Operator just need to put the whole barrel flux into the flux tank, meanwhile put the sucking tube into the barrel. |

|

● Forced air convection preheat zone control by temperature controller in PID model. The preheat zone will provide enough uniform heat for the PCB. Hot air motor speed is adjustable in the software interface. |

|

● eWa series is equipped with 3 individual bottom hot air zone, plus 1 individual top hot air zone, this configuration will provide the greatest preheating effect for soldering. |

|

● Dual wave nozzles. Both wave heights are controlled by transducer. wave height can be set on the software. |

|

● Solder pot is made of Ti material. Long life warranty. |

|

● High quality wave motor with small noise and more stable. |

|

eWA series Lead Free Wave Solder Machine Specification: |

|

|

Model |

eWA-450 |

|

PCB width |

max 450MM |

|

Running power /General power |

12KW/36KW |

|

Machine Dimension |

4465(L)*1550(W)*1812(H) |

|

Net Weight |

2100KG |

|

Controlling System |

PC+PLC control |

|

Infeeding Conveyor Height |

750mm+/- 20mm |

|

Conveyor Speed |

300MM-2000MM/Min |

|

Conveyor Type |

Heavy duty Ti finger |

|

PCB Direction |

Left to Right |

|

Flux adding |

Automatic |

|

Spray drive |

Stepper motor drive |

|

Sprayer |

ST-6 spraying nozzle |

|

Preheat |

3 bottom hot air convection zone+1 top hot air convection zone |

|

Preheat power |

5kw/zone |

|

Preheating temperature |

Max: 250℃ |

|

Length of preheating zone tunnel |

1800mm |

|

Solder Pot Volume |

Max :550kg |

|

Solder Usual Temperature |

MAX:280℃ |

|

Solder Pot Temperature Control Mode |

PID + SSR mode |

|

Solder Pot Material |

Titanium |

|

Solder Pot Temperature |

Max :300℃ |

|

Wave Number |

Dual Waves |

|

Solder Pot Up/Down |

Automatically |

|

Solder Pot In/Out |

Automatically |

|

Conveyor Type |

Heavy duty Ti finger |

|

Exhausting blower |

Standard equipped 2 set, connecting port diameter:200mm |

|

Air Supply |

3-5BAR |

|

Power supply |

3PH 380V 50HZ |

|

eWA series Lead Free Wave Solder Machine Includes: |

|

● Lead free wave solder machine eWA-450 |

|

● Spraying system driven by step motor and PLC controller |

|

● 1 top individual preheating zone; 3 bottom individual preheating zones |

|

● Titanium alloy dual wave solder pot |

|

● Heavty duty titanium alloy finger conveying system |

|

● PC and PLC control system |

|

● Exhaust blower * 2 set |

|

● 1 year parts warranty |

0 review for Donec eu furniture

Related Products

Lead Free Wave Solder Machine E400

- Model: E400

Add a review

Your email address will not be published. Required fields are marked