- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

Fast chip shooter SM471 PLUS

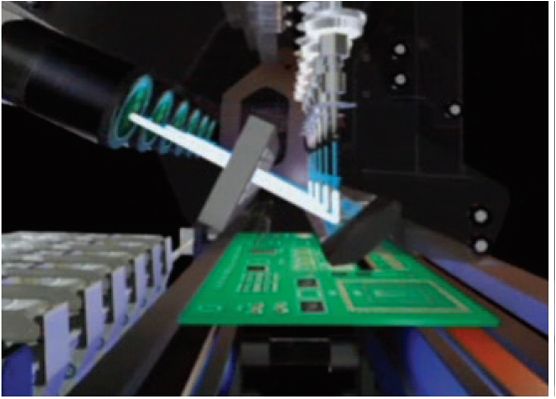

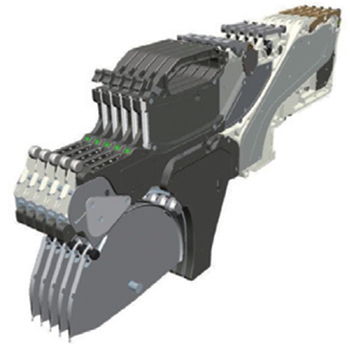

The SM471PLUS is a high performance chip shooer which applies two gantries equipped with 10 spindles per head as well as a new flying vision system. Compared to the existing SM471 model, its placement speed is increased further to 78,000CPH, which is the highest in the world among chip shooters of the same class. In addition, it is basically applicable to components from 0402(01005inch) chips to maximum 14mm IC components. Its actual productivity and placement quality is improved by applying high-speed and high precision electrical feeders. With two gantries and dual lane, the SM471PLUS supports various production modes to maximize the productivity of SM series machines.

Available Options

Fast chip shooter SM471 PLUS

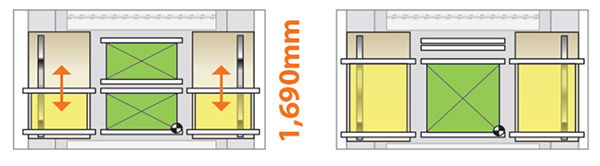

×Dual lane and shuttle conveyor maximizes the productivity of SM series component placers Dual lane production maximizes the productivity of small boards and the shuttle conveyor ensures extensibility to the production of large boards. |

|

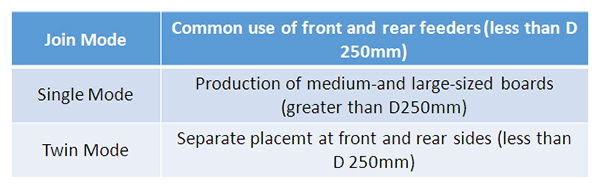

Supports for various production modes according to production chaaracteristics |

|

Even when a problem occurs to one placeent head or when the components, allowing continuous production without stopping the machine. |

|

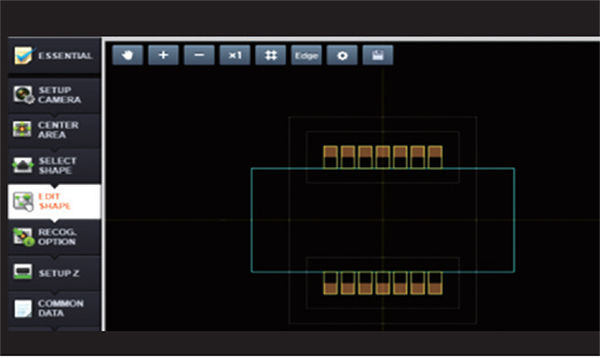

Panorama View Function Since large-sized components are not viewed in one screen, it is hard to adjust their pickup or placement positions. In order to remove such inconvenience, the panorama view function is added to allow large components to be viewedwithin the FOV of a camera. |

|

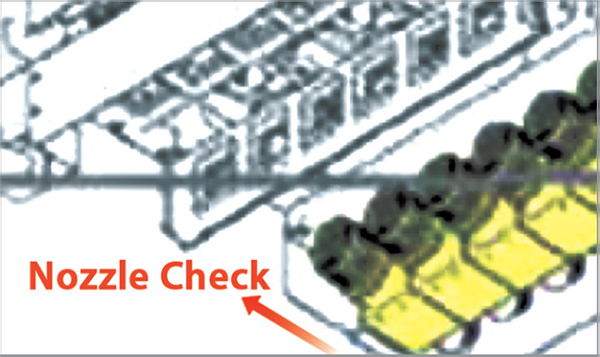

| Component Monitoring before/after Plancement Checks for nozzle contamination during production to prevent non-insertion and dumping of a large number of components in advance, ensuring high quality production. Time of inspection-Before/after ANC; before/after component placement; and after component dumping |

|

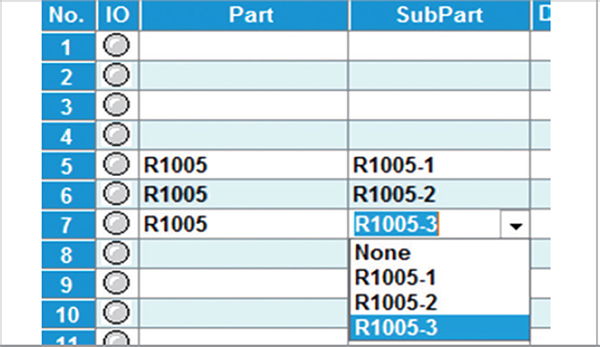

| Multi-Vendor Component Management Function When the same components are supplied from different component supply devices, this function allows components to be use without changing a PCB file and downloading a new PCB file. |

|

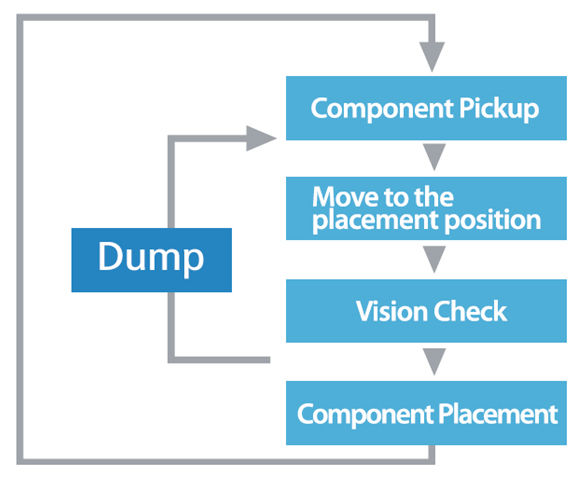

| On-the-fly Placement Method Owing to techwin's own On-the-fly image recognition technology which allows component recognition without stopping while moving after component pickup, placement speed is maximized by minimizing the moving time between the pickup position and placement position and reducing the recognition time to zero. |

|

| Added a new function maximizing the operational convenience of customers. |

|

Easy Component Registration New Part Editor A Drag & Drop component registration system, allowing registration of component informatic recognition and rotation by simply clicking the mouse. (When applying Elite2) In addition, user convenience is further reinforced by unifying the on-line/off-line comvenience is further reinforced by unifying the on-line/off-line component registration systems. |

|

| Mixed Use of Electric Feeder and Pneumatic Feeder Mixed use of electric and pneumatic feeders in the same feeder base is available for SM series component placers. The investment in production can be minimized by using these feeders along with existing feeders. |

|

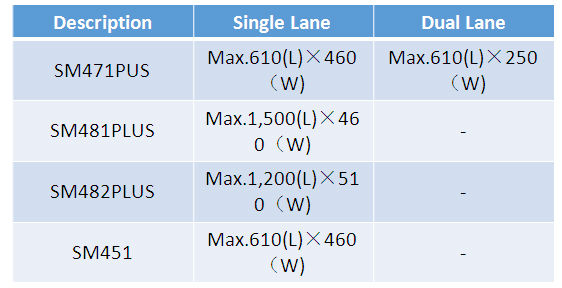

The highest applicability to long and large PCBs among machines of the same class |

|

SM471 PLUS Features | ||

1 | Placement Speed | Chip 78,000CPH(Optimal) |

2 | Applicable Component | 0402(01005inch)~Max. 14(h12mm) |

3 | Placement Accuracy | ±40μm@±3σ/Chip |

| ±50μm@±3σ/QFP | ||

4 | Applicable PCB | L510×W460×1Lane (Standard) |

| L610×W460(Option) | ||

SM471 PLUS Specification | |||

Model | SM471 PLUS | ||

Alignment | Flying Viion | ||

Number of Spindles | 10 Spindes × 2 Gantry | ||

Placement Speed | 78,000 CH (Optimum) | ||

Placement Accuracy | Chip | ±50μm@μ±3σ | |

| QFP | ±25μm@μ±3σ | ||

Component Range | Flying Vision | 0402(01005)~14mm IC, Connector (Lead Pitch 0.4mm) BGA,CSP (Ball Pitch 0.4mm) | |

| NA | |||

| Stage Vision | NA | ||

| NA | |||

| Max.Height | 12mm | ||

| Min. | 50(L)×40(W) | |

| Max. | Single Lane | 510(L)×460(W)/610(L)×460(W)Option | |

| Dual Lane | 460(L)×250(W)/610(L)×250(W)Option | ||

| PCB Thickness | 0.38~4.2 | ||

Feeder Capacity(8mm standard) | 120ea/112ea(Dacking Cart) | ||

Utility | Power | AC200/208/220/240/380/415V(50/60Hz, 3Phase) | |

| Max.5.0kVA | |||

| Air Consumption | 0.5~0.7MPa(5.0~7.0kgf/cm²) | ||

| 350Ne/min | |||

| 50Ne/min(vacuum pump) | |||

Mass(kg) | Approx.1820 | ||

External Dimension (mm) | 1650(L)×1690(D)×1485(H) | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 review for Donec eu furniture

Related Products

Advanced Flexible Mounter CM-S8

- Model: CM-S8

High Speed LED Mounter CM-S36

- Model: CM-S36

Juki RS-1

- Model: RS-1

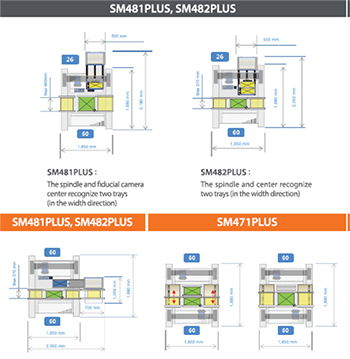

Flexible placer SM481 PLUS

- Model: SM481 PLUS

Odd shape component placer SM451

- Model: SM451

Add a review

Your email address will not be published. Required fields are marked