- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

Large board Dispensing Machine LD-600

Standard configuration: X/Y axis controlled by servo motor& ballscrew, max speed 1000mm/s Max W580*D580mm PCB capable Repeatable accuracy: +/-0.05mm Nozzle temperature control system Nozzle vacuum cleaning Liquid level in tube detecting system X/Y/Z axis auto correction platform

Large board Dispensing Machine LD-600

×|

Large Board Dispensing Machine LD-600 Details: |

|||||||||||||||||

|

|

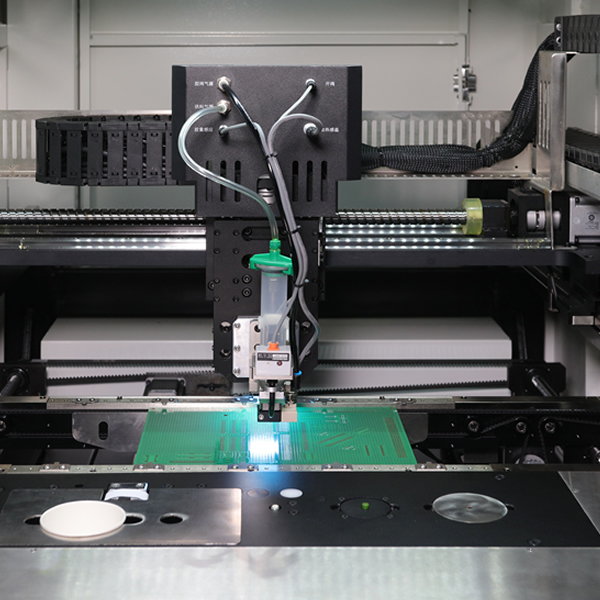

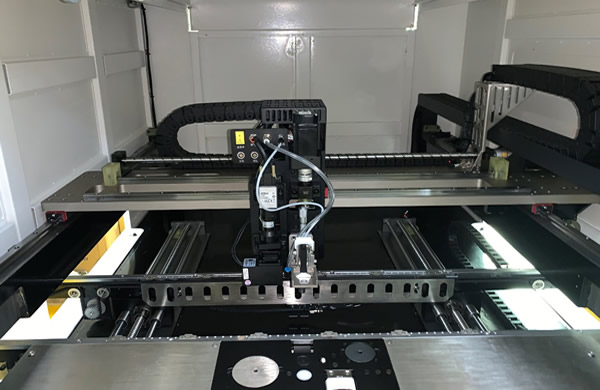

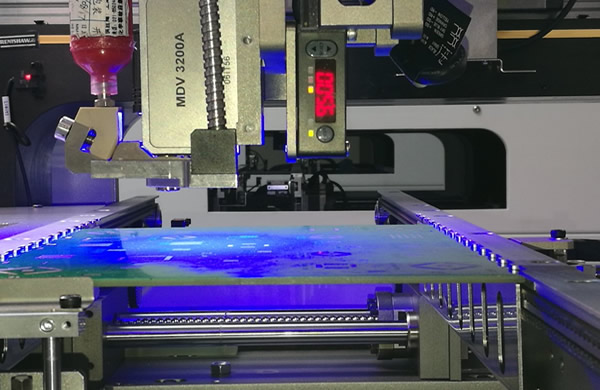

● Solid motion platform for LED board dispensing, X/Y axis is controlled by Fuji servo motor, max running speed can reach 1000mm/s. |

||||||||||||||||

|

|

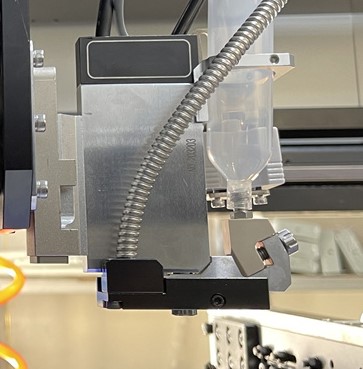

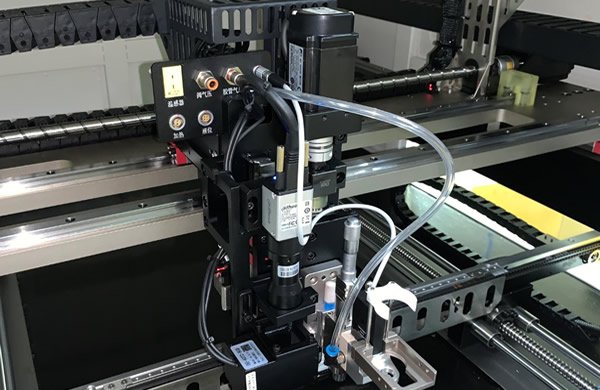

● Various high precision valve such as peumatic jet valve, piezoelectric jet valve, screw valve is choosable, to meet different dispensing requirement. |

||||||||||||||||

|

|

● Material level detection. ● Nozzle temperature control. |

||||||||||||||||

|

|

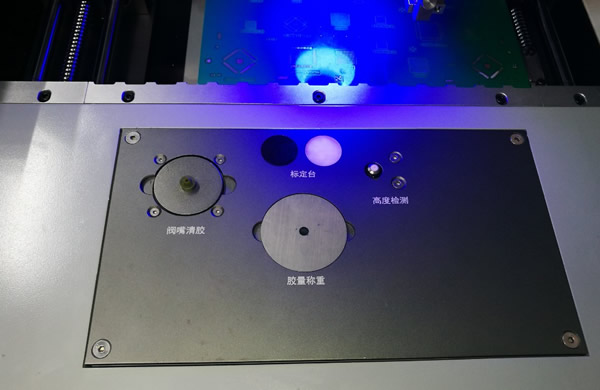

● X/Y/Z correction platform. ● Nozzle suction cleaning. ● Glue weighing device (option). |

||||||||||||||||

|

|

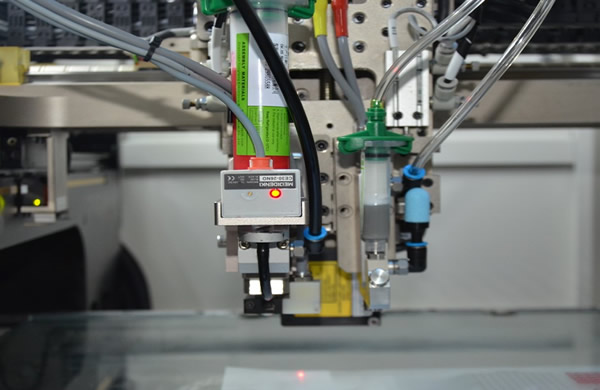

● Keyence laser height detecting system to correct the dispensing height. |

||||||||||||||||

|

Large Board Dispensing Machine LD-600 Software: |

|||||||||||||||||

|

1、Full english interface, software based on Windows 10 OS, easy to operate, It can realize Laser positioning, dot, line, circle, arc instruction.

2、Search function: Only need to edit one dispense location when PCB has many same components, others can be searched automatically and use the same dispense program to edit them. 3、It can locate fast through the images. Camera will locate the relevant position when click the image at the same time. It is very convenient to find the components.

4、Whole Panel Function, easy to setup panel with sub-program function. 5、Automatically check the dot image, and alarm if the dot is defective. 6、Software can load CSV file etc directly. |

|||||||||||||||||

|

Large Board Dispensing Machine LD-600 Valve: |

|||||||||||||||||

|

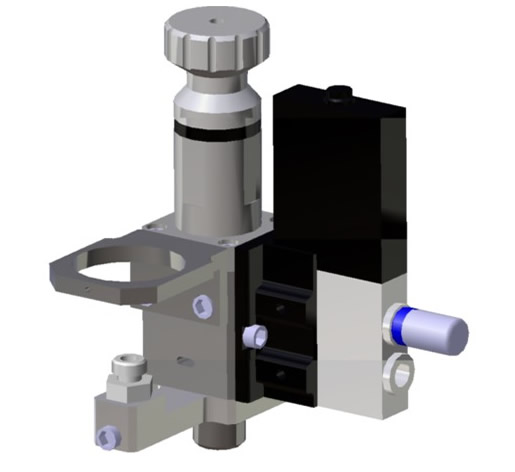

Peumatic Jet valve JET-6000 Features |

|

||||||||||||||||

|

|||||||||||||||||

|

Application : underfill Pin encapsulating conformal coating package on package dam&fill Red glue dispensing COB package |

|||||||||||||||||

|

Large Board Dispensing Machine LD-600 Valve: |

|||||||||||||||||

|

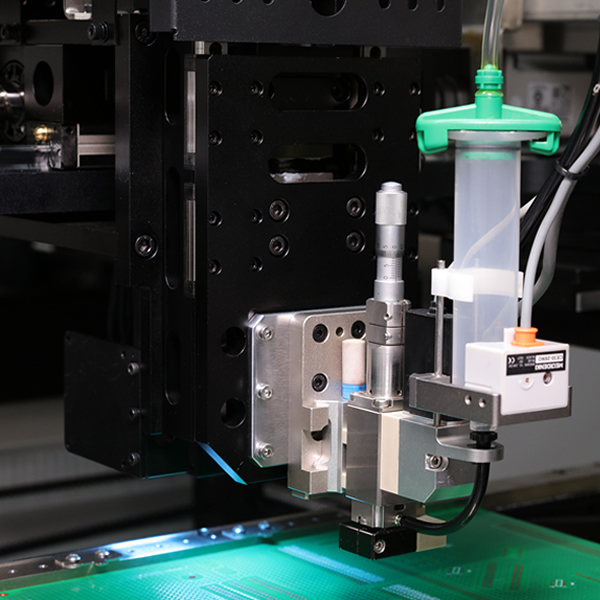

Piezoelectric Jet Valve VD-1000 Features |

● Extremely fast opening and closing of valve at full stroke with up to 3000 Hz. ● Freely adjustable parameter settings allow customizing the jet properties to require-- ments and fluid properties. ● Electronic control unit allows change of dispensing parameters without delay. ● High repeatability of drop-to-drop dispensing volume for media of all viscosities. ● Converting the force of the latest generation piezo through sophisticated mechanics. |

||||||||||||||||

|

|||||||||||||||||

|

|||||||||||||||||

|

Application: underfill Pin encapsulating conformal coating package on package dam&fill Red glue dispensing COB package |

|||||||||||||||||

|

Large Board Dispensing Machine LD-600 Features : |

|

● Solid motion platform for LED board dispensing, X/Y axis is controlled by Fuji servo motor, max running speed can reach 1000mm/s. |

|

● Various high precision valve such as peumatic jet valve, piezoelectric jet valve, screw valve which can meet different dispensing requirement. |

|

● Equipped with vacuum cleaning device, which improved the nozzle cleaning effect. |

|

● Keyence laser height detecting system(Option) to correct the dispensing height. |

|

● Material level detecting in syringe fuction , machine will alarm when material is insufficient. |

|

● Equipped with X/Y/Z auto correction platform. |

|

● Glue weighing function (Option) gurantees precise dispensing. |

|

● Industrial CCD and it's mark positioning function. |

|

● Teaching with CCD for programming , support loading CAD file. |

|

● Automatic detection of glue size, machine will alarm if detect unqualified glue point. |

|

● Industrial PC, Windows operation system, full english interface, very easy to use. |

|

Large Board Dispensing Machine LD-600 specification : |

|

|

Model |

LD-600 |

|

Overall size |

1100*1390*1500(L*W*H) |

|

Control method |

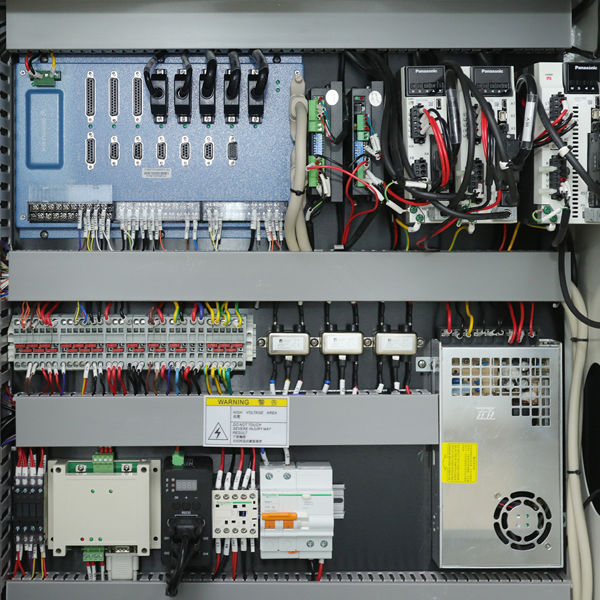

Industrial PC, full English software based on Windows 10 OS |

|

Visual System |

fiducial mark recognition and automatic correct coordinate offset |

|

Conveyor |

One section conveying, conveying height: 900+/- 20mm, left to right only. |

|

Width adjustment |

Single Lane: 80~580mm, automatic width adjustment |

|

X/Y axis Drive Model |

Servo Motor |

|

Z Axis Drive Mode |

Servo Motor |

|

Maximum Speed |

X/Y: 1000mm/S |

|

Repeatable Accuracy |

0.025mm |

|

Dispensing Area |

X=580mm, Y=580mm |

|

Valve Heating |

Room Temperature~80℃±3℃ |

|

Material Volume |

30CC Or 50CC |

|

Material Detection |

Automatically Inspect glue dispensing size. |

|

Nozzle Cleaner |

Vacuum Cleaning |

|

Communication Connector |

SMEMA |

|

Program Method |

CAD file load, Manual Teaching. |

|

Power Supply |

1P,220V 50~60HZ |

|

Air Pressure |

7kg/cm2 |

|

Power |

Max 2.5KW |

|

Machine Weight |

680kg |

|

Large Board Dispensing Machine LD-600 configuration: |

|

Standard machine includes: |

|

● X/Y/Z axis controlled by servo motor. |

|

● Industrial PC, monitor, Keyboard, mouse. |

|

● 1 section conveyor controlled by step motor with automatic adjustment |

|

● 3 color alarm lamp |

|

● CCD visual system |

|

● Nozzle heating |

|

● Nozzle cleaning device |

|

● Liquid level in tube detecting device |

|

● X/Y/Z axis auto correction platform |

|

● SMEMA cable |

|

● 1 year parts warranty |

|

|

|

Optional configuration: |

|

● China made pneumatic jet valve |

|

● VERMERS Piezoelectric jet valve |

| ● China made piezoelectric jet valve |

|

● Precision glue weighing system |

| ● Laser height detecting system |

|

● Air pressure boosting pump (for pneumatic jet valve) |

|

● Bottom heating device |

|

● Bar code reading system |

2 review for Donec eu furniture

wspnet - 2020-12-26 01:29:52

Your email address will not be published. Required fields are markedAdd a review

Your email address will not be published. Required fields are marked

Related Products

Ultra Speed Dispensing Machine JD-450

- Model: JD-450

Benchtop Dispensing Machine SD-400i

- Model: SD-400i

Single Station Benchtop Dispensing Machine GR-300S

- Model: GR-300S

Double Station Benchtop Dispensing Machine GR-300S2Y

- Model: GR-300S2Y

5 Axis Benchtop Dispensing Machine GR-400B

- Model: GR-400B

dsfasdfasd - 2020-12-26 01:15:36

dfasdfasd