- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

NG OK Magazine Unloader Series

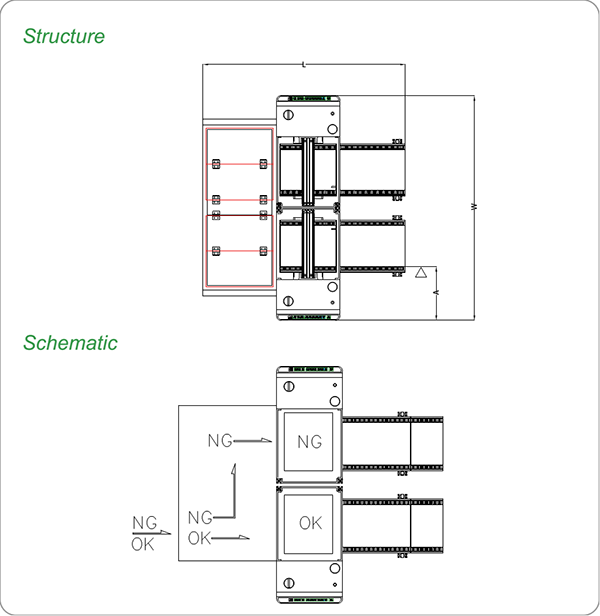

The PCB's are collected from upstream machine onto a shuttle conveyor and pushed into designated magazine. Shuttle conveyor moves sideways between upstream machine and magazines.

Available Options

NG OK Magazine Unloader Series

×NG OK Magazine Unloader Series Features

|

● Pannasonic PLC Program control. |

|

● Selectable pitch settings. |

|

● Good or bad board separation. |

|

● Unique guide rail driven positioning of shuttle conveyor. |

|

● Towerlight display for machine status. |

|

● Additional mgazines buffing capacity available upon request. |

|

● Conveyor width adjustment using hand wheel. |

|

● Automatic magazine alignment by upper- and lower pneumatic lamping. |

|

● Regulated pressure on attached pneumatic pusher. |

|

● Pusher position adjustable to centre of the magazine. |

|

● User friendly “soft touch” LED membrane control panel. |

|

● SMEMA compatible. |

NG OK Magazine Unloader Series Specifications

|

● Transport height: |

910mm ±30mm |

|

● Transfer direction: |

Left to right |

|

● Operation side: |

Front of the machine |

|

● Fixed rail: |

Front of the machine |

|

● Interface: |

SMEMA |

|

● Conveyer concept: |

ESD belt (round or flat) |

|

● Belt speed: |

16m /min |

|

● PCB edge support: |

3mm |

| ●Components clearance: | Top 30 mm, bottom 30 mm (depends on pitch) |

|

● Power supply: |

230 VAC/50 Hz/1 Ph |

|

● Power consumption: |

500VA max. or specify |

|

● Air supply: |

4-6 bar |

|

● Air consumption: |

10 ltr/min max. |

|

● PCB unloading time: |

±10 seconds |

|

● Magazine change-over time: |

± 30 seconds |

|

● Pitch distance: |

10.20.30.40mm pitch or specify. |

|

● Max. total magazine weight: |

50 kg each * or specify |

|

Model |

ULDC250M |

ULDC330L |

ULDC390LL |

ULDC460XL |

|

Machine Dimension (L x W x H) |

1500 x 1550 x 1350 |

1860 x 1700 x 1350 |

2150 x 1800 x 1350 |

2150 x 1950 x 1350 |

|

Weight |

220kg |

320kg |

380kg |

400kg |

|

PCB length |

50mm - 330mm |

50mm - 445mm |

50mm - 530mm |

50mm - 530mm |

|

PCB width |

50mm - 250mm |

50mm - 330mm |

50mm - 390mm |

50mm - 460mm |

|

PCB Thinckness |

0.6mm – 4.5mm |

0.6mm – 4.5mm |

0.6mm – 4.5mm |

0.6mm – 4.5mm |

|

Magazine Dimensions (max.) |

355 x 320 x563 |

460 x 400 x 560 |

535 x 460 x 570 |

535 x 530 x 570 |

|

Fixed rail to front dimension(A) |

367mm |

367mm |

367mm |

367mm |

* Customized is available

NG OK Magazine Unloader Series Options

|

● Automatic width adjustment for shuttle conveyor. |

|

● Additional magazine capacity. |

|

● Touchscreen instead of button panel. |

|

● Enclosed construction improve level of safety. |

| ● Other options available on request. |

0 review for Donec eu furniture

Related Products

Inspection Conveyor Series

- Model: CYB

High Version Conveyor Series

- Model: CYX

High Version Reject Conveyor Series

- Model: CYCX

Reject Conveyor Series

- Model: CYC

Telescopic Conveyor Series

- Model: CYT

Add a review

Your email address will not be published. Required fields are marked