- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

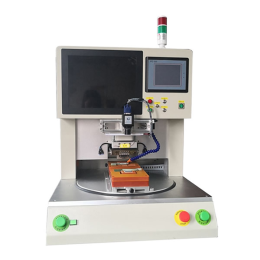

Precise resistance soldering machine WZ-04LB

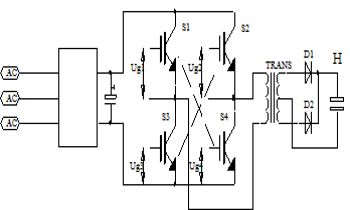

Precision resistance welding machine using AC-DC-AC-DC conversion technology to implement DC spot welding, compared to frequency AC spot welding technology, DC spot welding high quality, fast welding, energy saving effect, small size, light weight equipment. Using the MCU precise control of welding process, real-time monitoring and display the current welding current and other parameter values.

Available Options

Precise resistance soldering machine WZ-04LB

×

|

|

| Inverter resistance welding power supply: DC output. Welding current is pulsating DC, waviness is small, no AC zero cross-heating workpiece shortcomings, heat concentration, improve the thermal efficiency of welding for non-ferrous materials and some difficult welding of welding materials particularly suitable for welding process stability, welding quality Significantly increased. At the same time the electrode life has been extended. | By adjusting the size of the air pressure to control the soldering pressure |

|

![7EC}OT5GB~MU]~%9B4CP(5E.jpg 7EC}OT5GB~MU]~%9B4CP(5E.jpg](/Data/1clicksmt-oddinsertion/upload/image/20201009/6373783859901552853332155.jpg)

|

| Using AC-DC-AC-DC conversion technology, making the time control can reach milliseconds and accuracy, control response and control accuracy has been greatly improved.Inverter bridge current automatic shutdown, and enhance system protection |

Current soldering waveform |

|

|

| Separate increase pressure adjustment knob:Together with the air pressure to adjust the soldering pressure. | Throttle valve : By controlling the cylinder throttle valve to adjust the rise and fall speed |

![[KDJK_PL]KW[FJ9V(5E`}7F.jpg [KDJK_PL]KW[FJ9V(5E`}7F.jpg](/Data/1clicksmt-oddinsertion/upload/image/20201009/6373783859906167441178066.jpg)

|

|

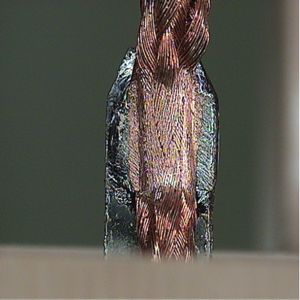

| Electrode: The electrode is made of tungsten alloy, has a strong high temperature hardness and strength, at room temperature and high temperature environment has good electrical conductivity and thermal conductivity. And strong antioxidant capacity. |

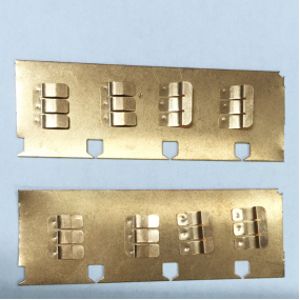

Customized soldering electrodes

Customized fixture |

|

![_4Q}E(T4D{6}C`5VG]F7_AN.jpg _4Q}E(T4D{6}C`5VG]F7_AN.jpg](/Data/1clicksmt-oddinsertion/upload/image/20201009/6373783859910248997321483.jpg)

|

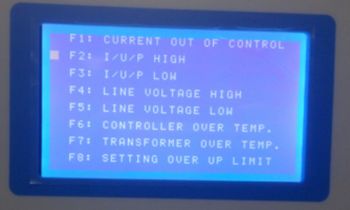

| Three-stage heating setting, with the current slow rise and slow down function, the time is set to (0-250ms or 0-1s), suitable for complex welding process needs.The soldering current is displayed on the LCD screen in real time |

Current upper and lower limit setting interface , real-time monitoring current current is beyond the se tting range |

|

Warning interface : Displays the current error

|

Precise resistance soldering machine WZ-04LB Features

|

● Soldering parameters adjustment and soldering process display by LCD.Intuitive graphical user interface. |

|

● Constant current,constant voltage,constant power modes and pulse width control mode. |

|

● Trinal pulse waveforms programmed in current,voltage or power control mode .Up & Down Slope control. |

|

● Monitoring the seting parameters with up and down limits. |

|

● Using IGBT inverter technology, MCU and modern power electronic technology development of new power supply. |

|

● Inverter bridge using soft-switching technology, smaller switching losses, reduce electromagnetic interference. |

|

● 20 groups of parameters stored, can be used to store a variety of welding types of product parameters |

| ● Inverter bridge current automatic shutdown,and enhance system protection. |

|

Precise resistance soldeing machine specification |

||||||

|

Model |

Input voltage(V) |

rated power(kVA) |

Maximum output current(DCA) |

Control mode |

Duty cycle(%) |

Inverter frequency(kHz) |

|

WZ-04LB |

3~380V |

12 |

4000 |

Constant current mode/Constant power mode/Constant voltage mode/Constant pulse width mode |

10 |

4 |

|

Welding cycle time |

Number of soldering pulses |

Current ramp-up and ramp-down control |

Soldering Parameters Storage Quantity (Group) |

Dimensions(mm)(L*B*H) |

weight(kg) |

|

|

11 |

3 |

have |

20 groups |

460*400*300 |

33 |

|

Application:

|

![{F7NRXJ`1E6Q7]QA9IFA74E.jpg {F7NRXJ`1E6Q7]QA9IFA74E.jpg](/Data/1clicksmt-oddinsertion/upload/image/20201009/6373783869386431759648981.jpg)

|

|

A multi-strand copper wire is soldered to a copper sheet plated with zinc |

A multi-stranded wire was soldered to a nickel-plated copper foil |

![@QZ%$JM}NYMV2SQ}]$[%N9F.jpg @QZ%$JM}NYMV2SQ}]$[%N9F.jpg](/Data/1clicksmt-oddinsertion/upload/image/20201009/6373783869387744491518155.jpg)

|

|

| LED light bar soldering | LED light bar soldering |

|

|

| Copper, stainless steel pieces, and so are the hardware with a resistance spot welding |

Copper, stainless steel pieces, and so are the hardware with a presistance spot welding |

![EGG6@NA3KSCXDH]D]SUTQG8.jpg EGG6@NA3KSCXDH]D]SUTQG8.jpg](/Data/1clicksmt-oddinsertion/upload/image/20201009/6373783869393182157715097.jpg)

|

|

|

The motor rotor inside the enameled wire and the terminal of the welding, is the use of resistance spot welding

|

|

0 review for Donec eu furniture

Related Products

Hot Bar Soldering Machine HBS-A4

- Model: HBS-A4

Hot Bar Soldering Machine HBS-4AT

- Model: HBS-4AT

Hot Bar Soldering Machine HBS-A3

- Model: HBS-A3

Double Station Hot Bar Soldering Machine HBS-4AM

- Model: HBS-4AM

Add a review

Your email address will not be published. Required fields are marked