- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

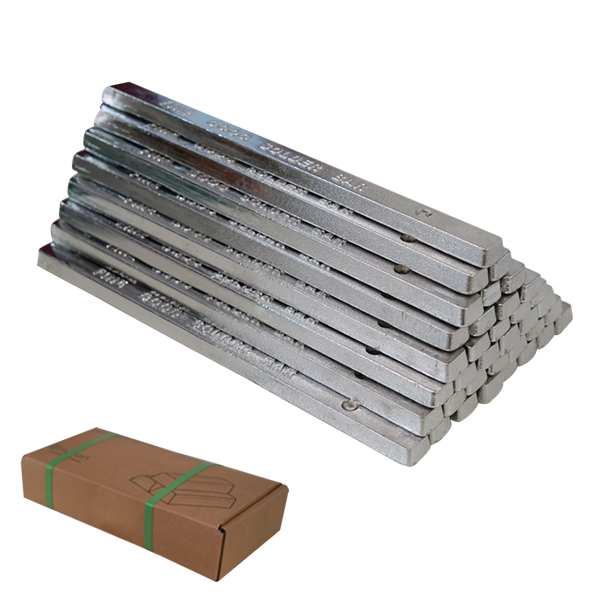

Sn63/Pb37 Bar Solder

Our solder bars with different compositions comply with industry standards and ordinary solder bars are all made with high quality alloys, advanced smelting technology and strict quality control, thus reducing the contents of impurity elements such as copper, calcium, zinc, aluminum and iron to the lowest level when welding, to ensure that you get good and reliable solder joints.

Available Options

Sn63/Pb37 Bar Solder

×Solder bar itself has been added with antioxidant and such antioxidant is constantly released to the surface of solder liquid, forming a layer of thin film to prevent the solder from direct contact with air, achieving the goal of antioxidization. But, along with the long-term use, antioxidant will reduce, therefore more antioxidant must be added continuously, namely adding more solder bars. It would be the best to add solder bars every two hours instead of once a day. This way, the solder surface can give full play to its antioxidation.

|

Sn63/Pb37 solder bar Alloy compositions and contents: |

||||

|

Description |

Sn63/37 solder bar |

Specification | Sn63/Pb37 | |

|

Seq |

Test items |

Contents (in WT%) |

||

|

Alloy compositions meet industry specifications as follows: |

||||

|

1 |

Tin (Sn) |

63±1.5 |

||

|

2 |

Lead (Pb) |

The rest |

||

|

Impurity limit ≤ |

||||

|

3 |

Stibium (Sb) |

0.8 |

||

|

4 |

Bismuth (Bi) |

0.08 |

||

|

5 |

Iron (Fe) |

0.02 |

||

|

6 |

Arsenic (As) |

0.02 |

||

|

7 |

Copper (Cu) |

0.05 |

||

|

8 |

Zinc (Zn) |

0.002 |

||

|

9 |

Alumimium (Al) |

0.005 |

||

|

10 |

Cadmium (Cd) |

0.005 |

||

|

Note: The above alloys were determined by densitometry. Final tin content = tin content + antimony content |

||||

|

Packing and labelling |

|

1. Packing size: 25kg/box (±0.02KG) |

|

|

|

2. Labeling: Description, weight, manufacture date, lot number, etc. |

|

|

|

3. Shelf life: One year when stored between 0~40℃ |

|

|

|

4. Precautions: Stored in a dry and ventilated place and keep away from moisture |

.jpg)

Add a review

Your email address will not be published. Required fields are marked