- Call us now: (+86)0769-85303739

- Email: sales@1clicksmt.com

ZERO ION G3-500A Ionic Contamination/Cleanliness Tester

ZERO ION G3-500A is our third generation IPC J-STD approved resistivity of solvent extract (ROSE) tester. Today's Zero Ion is more feature rich and operator friendly than ever before and the dynamic measurement technology continues to provide accurate and highly sensitive cleanliness measurement results essential for modern high reliability manufacturing environments.

Available Options

ZERO ION G3-500A Ionic Contamination/Cleanliness Tester

×|

|

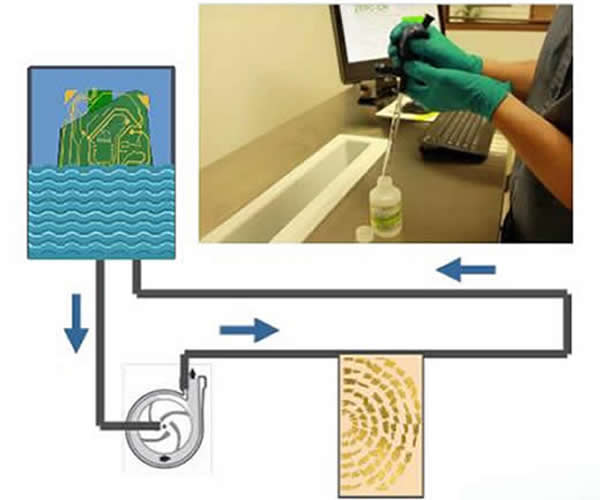

Dynamic Rose Testing ● ZERO ION is an industry standard for resistivity of solvent extract testing. The dynamic measurement technology provides sensitive and precise cleanliness data in compliance with WS 6536, IPC J-STD 001 TM 650 and other current specifications. ● The dynamic method was found to be the most sensitive ionic contamination test by the EMPF/US Navy MIL2000A. The spray under immersion and continuous filtration design allow for repeatable and accurate process monitoring results. |

|

|

Reliability Matters ● During a test the ZERO ION will automatically regenerate the test solution to 150 meg-ohms of resistance and then prompt an operator to insert an assembly. Testing will then automatically begin and continue until the solution again reaches 150 meg-ohms. This continuous filtration, while spraying the assemblies under immersion, allows for optimal removal and measurement of ionic process residues, expressed as ug/in2 / ug/cm2. |

|

|

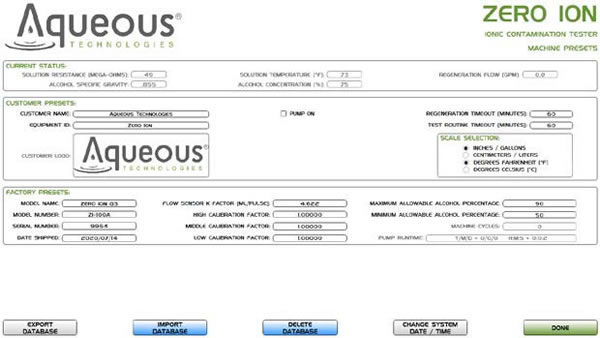

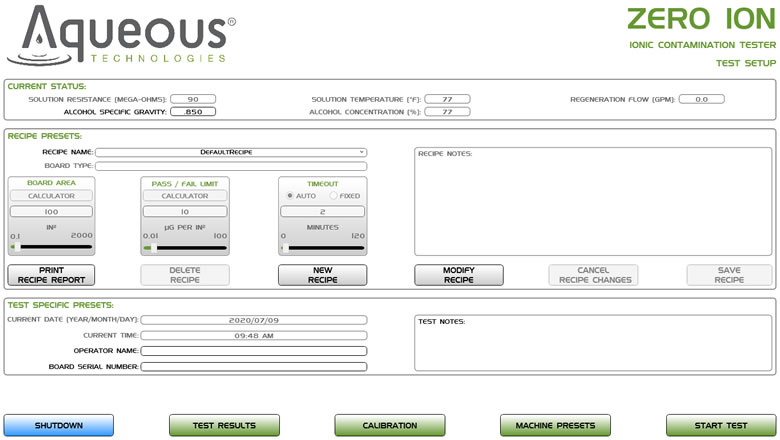

Process Controls ● The control platform developed for ZERO ION combines a simplistic operator experience with a versatile and robust program. Features include barcode scanning, an SQL database server, aSPC recording, password protected recipes, contamination reports and graphs, data networking and virtually unlimited recipe storage. |

|

|

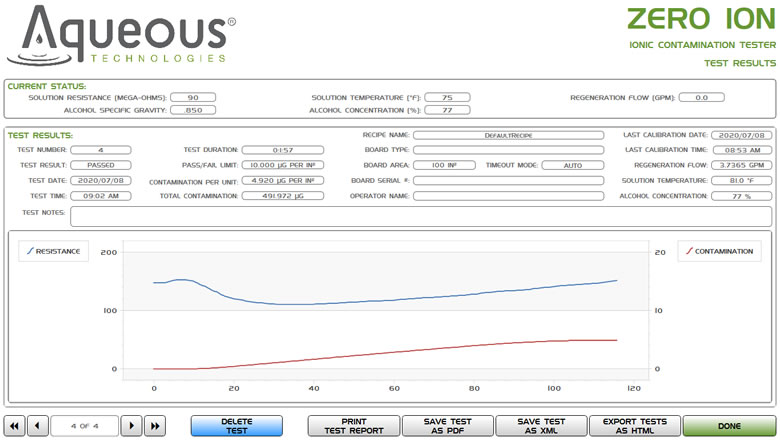

Process Controls ● Testing data including pass/fail status, contamination per in2/cm2, times, operator information, assembly notes, and more is available for printing, PDF writing and networking after every test. Reports are also logged into the searchable database and can be accessed at the touch of a button. |

|

ZERO ION G3-500A Ionic Contamination/Cleanliness Tester Features |

|

● Ultra sensitive dynamic measurement technology. |

|

● Built-in universal assembly holder. |

|

● Windows 10 all-in-one PC platform. |

|

● Heavy-duty rolled stainless steel frame and panel construction. |

|

● Advanced statistical process control (spc) data logging. |

|

● Non-heated spray under immersion with continuous filtration. |

|

● Sql multi-query searchable database. |

|

● Graphic touchscreen and keyboard operator interface. |

|

● Intuitively guided calibration procedures built into software. |

|

● Automatic recipe recall. |

|

● Wired and wireless network options. |

|

● Built-in assembly surface area calculators. |

|

● Included pdf report writer PDF. |

|

ZERO ION G3-500A Ionic Contamination/Cleanliness Tester Specification: |

|

|

Model |

G3-500A |

|

Weights and Dimensions: |

1350L×715W×900Hmm (75KG) |

|

Power Requirements: |

230 VAC 5 amps 50/60 Hz |

|

Contamination/Unit: |

ug/in2 or ug/cm2 |

|

Testing Method: |

dynamic test method spray under immersion |

|

Solution Resistance: |

150MΩ |

|

Test Solution: |

Isopropanol 99% 75% Isopropanol/ 25% Deionized Water (By Volume) |

|

Test Cell Sizes: |

24" x 24" / 61cm x 61cm custom test cells available |

|

Incldued Accessories: |

Test solution |

| Calibration solution | |

| Digital Pipette | |

| Hydrometer | |

| Keyboard and mouse | |

|

Standards Compliance: |

IPC Tm 650 J-STD 001 WS 6536 |

|

Calibration Rang: |

500ug/1000ug/2000ug |

|

Accuracy / Min.Resolution: |

5% / 0.001ug |

|

Calibration Solution: |

NaCl and H2O |

|

Di Media Tank: |

6L |

|

Control System: |

Windows 10 operating system |

| Teguar all-in-one PC | |

|

Construction Materials: |

Hrs - hot rolled steel frame |

| Silver hammer tone powder coat finish | |

| Polypropelyne test cell | |

|

Consumables: |

Test solution |

| Calibration solution | |

| DI media filter | |

|

Test Screen: |

|

|

|

|

Add a review

Your email address will not be published. Required fields are marked